Method for treating fluorine-containing and ammonia nitrogen-containing waste water in electronic industry

A technology for electronic industry and ammonia nitrogen wastewater, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. , poor biodegradability and other problems, to achieve the effect of reducing fluoride ion content and ammonia nitrogen content, stable treatment effect and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The wastewater containing fluorine and ammonia nitrogen in an electronics industry contains a large amount of pollutants such as fluorine, ammonia nitrogen, organic nitrogen, phosphorus and suspended solids, and the total dissolved solid salt content in the water is relatively high. See Table 1 for the content of main pollutants in specific wastewater.

[0028] Table 1: Contents of main pollutants in wastewater containing fluorine and ammonia nitrogen

[0029] Ammonia nitrogen

Ammonia nitrogen / fluoride ion

COD

SS

TDS

pH value

20mg / L

26mg / L

55mg / L

0.36

50mg / L

50mg / L

4.8mg / L

2000mg / L

6~9

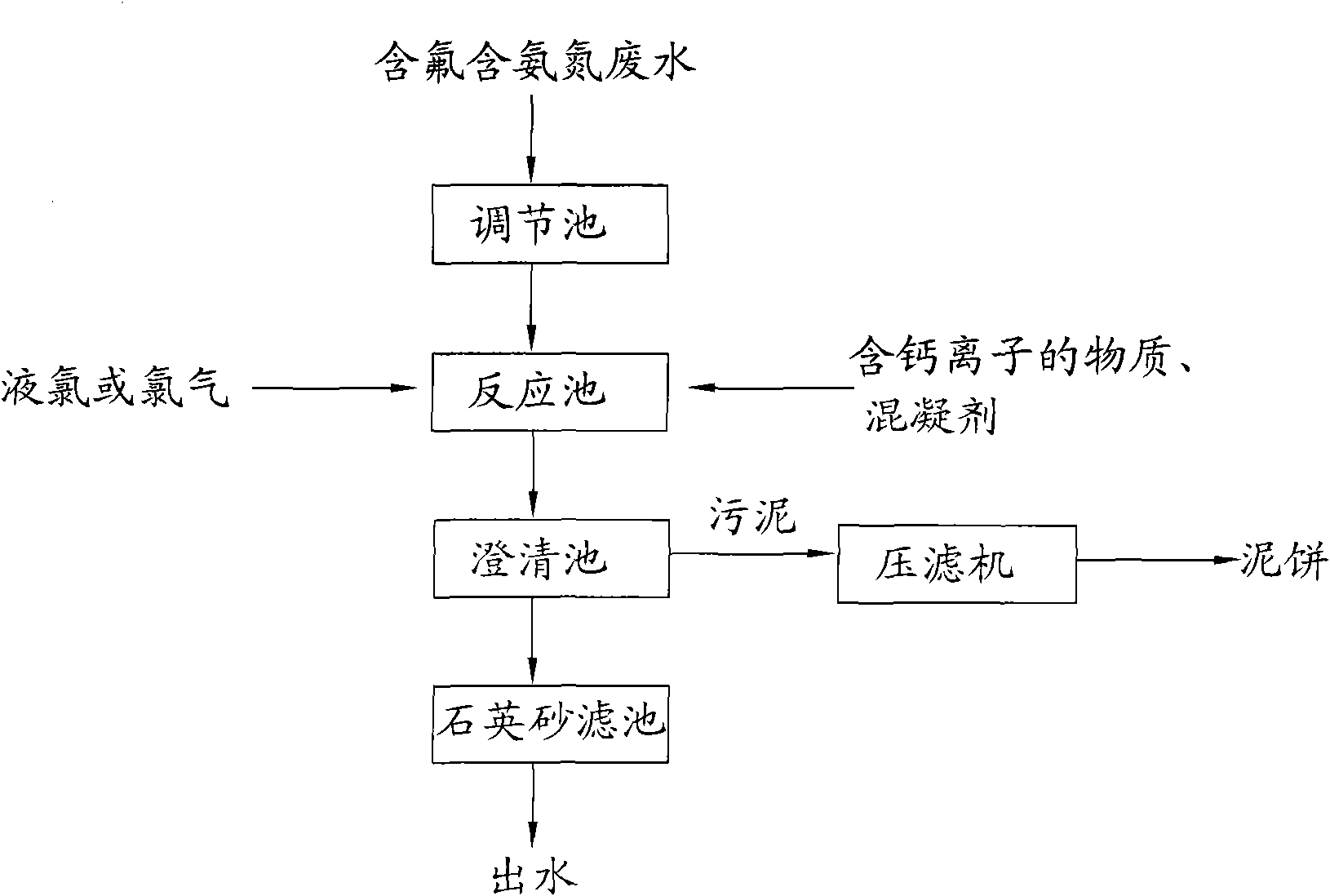

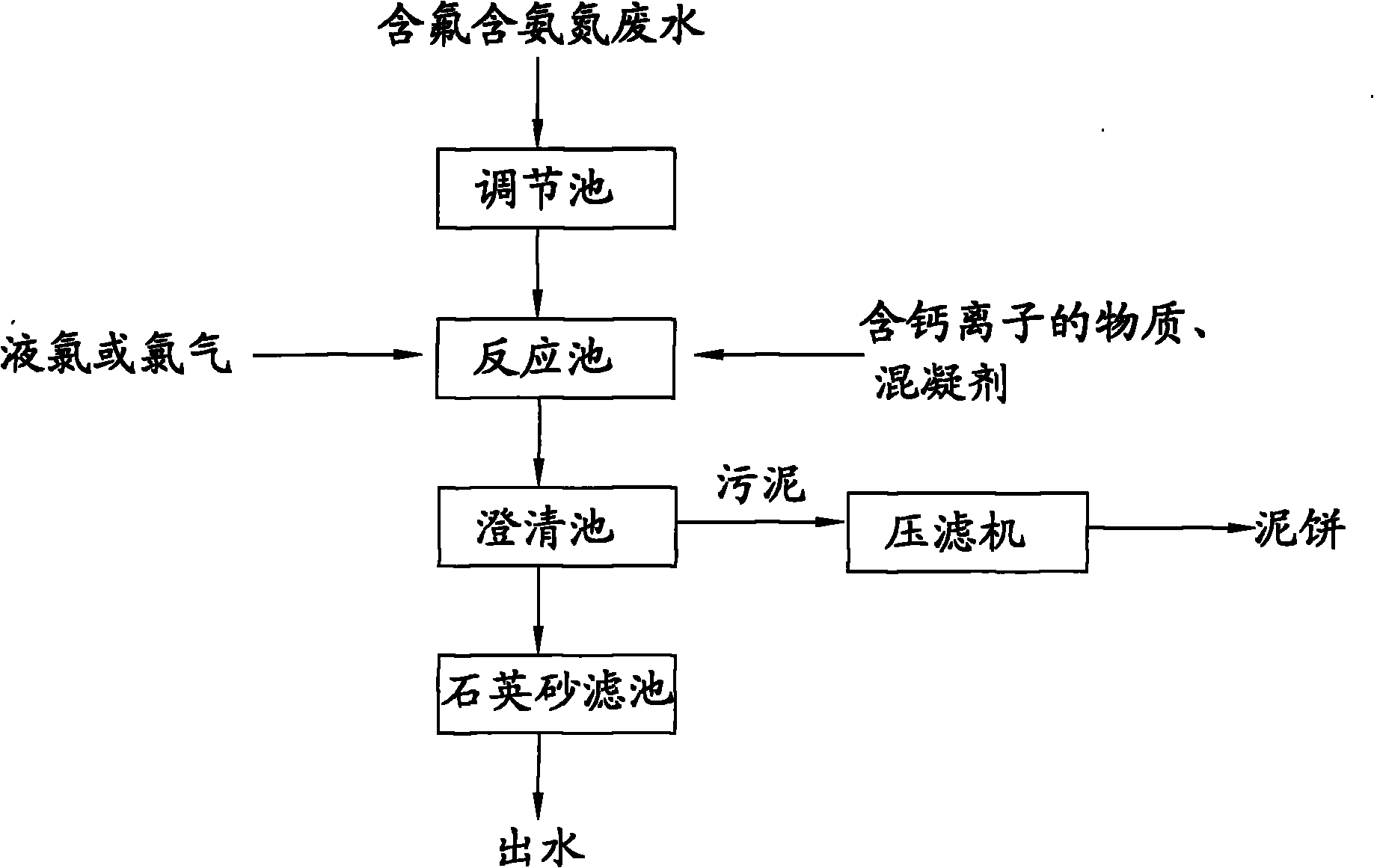

[0030] Such as figure 1 As shown, the waste water is sequentially passed through the adjustment tank, the reaction tank, the clarification tank and the V-type quartz sand filter for the removal of fluorine and ammonia and nitrogen. The specific treatment proc...

Embodiment 2

[0044] The wastewater containing fluorine and ammonia nitrogen in an electronics industry contains a large amount of pollutants such as fluorine, ammonia nitrogen, organic nitrogen, phosphorus and suspended solids, and the total dissolved solid salt content in the water is relatively high. The specific content of main pollutants in wastewater is shown in Table 2.

[0045] Table 2: Contents of main pollutants in wastewater containing fluorine and ammonia nitrogen

[0046] Ammonia nitrogen

Fluoride ion

Ammonia nitrogen / fluoride ion

COD

SS

phosphorus

TDS

pH value

25mg / L

32mg / L

50mg / L

0.50

50mg / L

50mg / L

4.8mg / L

2000mg / L

6~9

[0047] The principle of the waste water treatment method according to this embodiment is the same as that of Example 1, but its specific operation process is different, and it is specifically carried out in the following manner: first add the first batch of...

Embodiment 3

[0050] The wastewater containing fluorine and ammonia nitrogen in an electronics industry contains a large amount of pollutants such as fluorine, ammonia nitrogen, organic nitrogen, phosphorus and suspended solids, and the total dissolved solid salt content in the water is relatively high. See Table 3 for the content of main pollutants in specific wastewater.

[0051] Table 3: Contents of main pollutants in wastewater containing fluorine and ammonia nitrogen

[0052] Ammonia nitrogen

total nitrogen

Fluoride ion

Ammonia nitrogen / fluoride ion

COD

SS

phosphorus

TDS

pH value

35mg / L

43mg / L

37mg / L

0.95

50mg / L

50mg / L

4.8mg / L

2000mg / L

6~9

[0053] The principle of the waste water treatment method according to this embodiment is the same as that of Example 1, but its specific operation process is different, and it is specifically carried out in the following manner: first add the first batch of liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com