Method for manufacturing normal pressure reinforced wax mould head

A manufacturing method and technology of wax patterns, applied in the direction of casting molding equipment, etc., can solve the problems of wax pattern strength reduction, loss, low wax pattern density, etc., and achieve the effects of improved product qualification rate, strong adsorption, and solid interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Prepare a "one"-shaped wax model with a length of 600 mm, a thickness and a width of 8 mm. its shape like image 3 .

[0016] Its production steps are as follows:

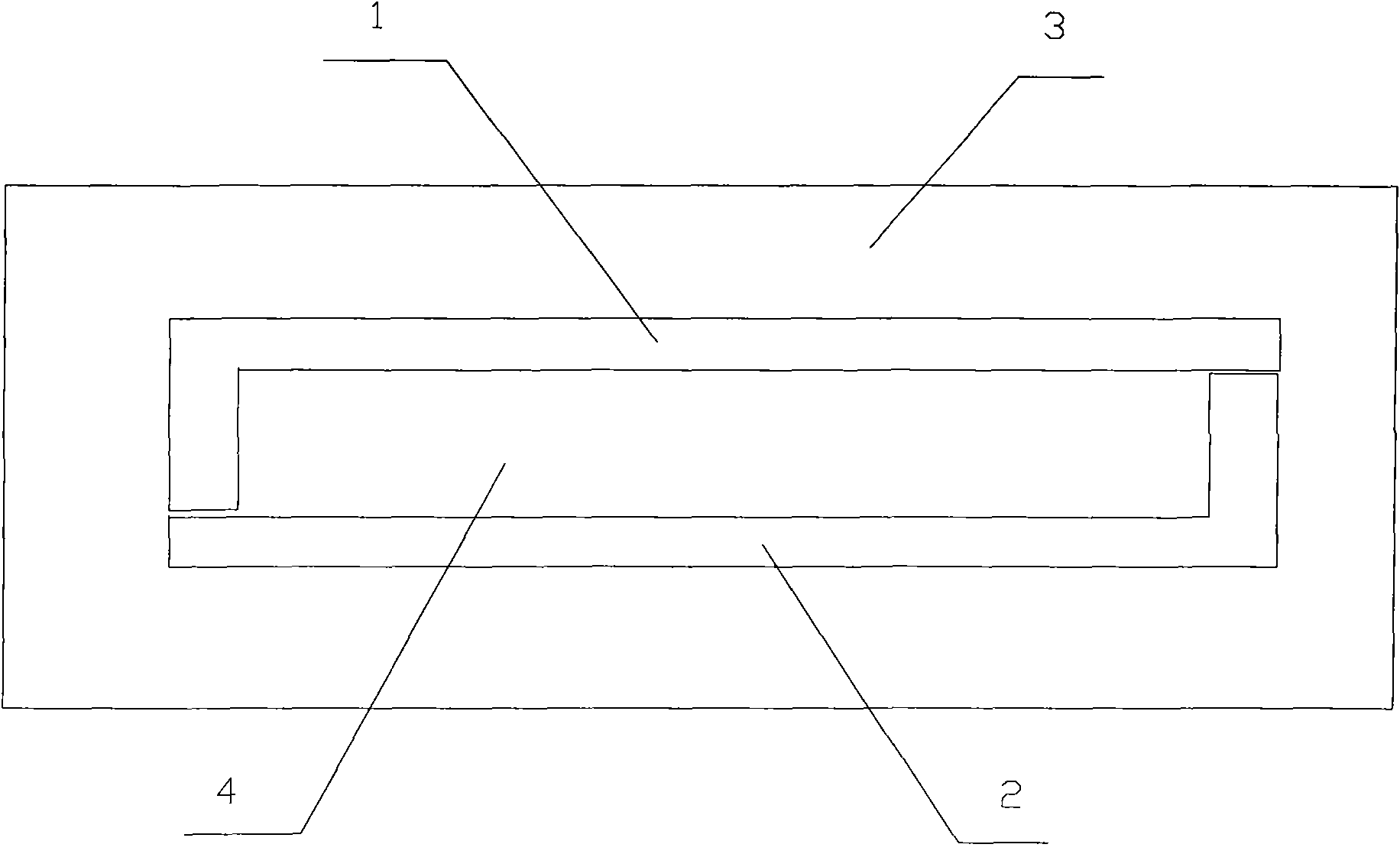

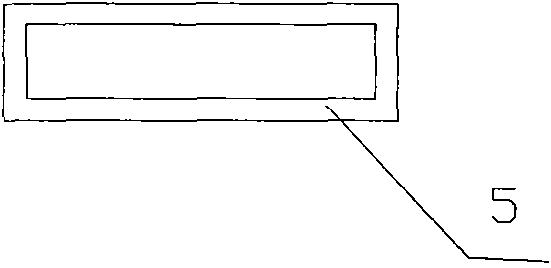

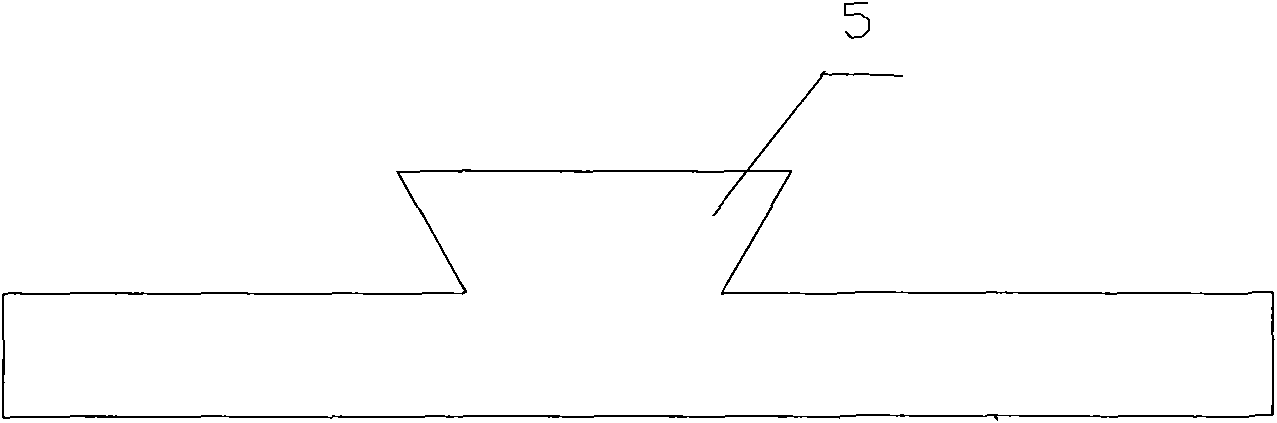

[0017] 1. First make discrete mold components: two aluminum alloy strips with a length of 600mm and a beam with a length of 80mm at one end are cast through sand casting, as discrete mold components 1 and 2, such as figure 1 shown. Place the two discrete mold assemblies 1 and 2 on the metal flat plate 3, and form a "one"-shaped cavity 4 between the two discrete mold assemblies 1 and 2 to form a "one"-shaped wax mold wax pattern mold. Simultaneously, also select the high-pressure die head 5 of the bucket-shaped high-pressure band gate wax cup similar to the shape of the "one"-shaped cavity 4, and the width of the high-pressure die head 5 of the bucket-shaped high-pressure band gate wax cup is 40mm, which is equivalent to 1 / 2 of the length of the "one"-shaped cavity 4; the width of the wax mold head 5 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com