Photosensitive letterpress printing original plate

A letterpress printing and photosensitivity technology, applied in the field of photosensitive letterpress printing original plate, can solve problems such as poor damage resistance, increased layer thickness, poor dispersion state of carbon black, etc., and achieve high light blocking and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

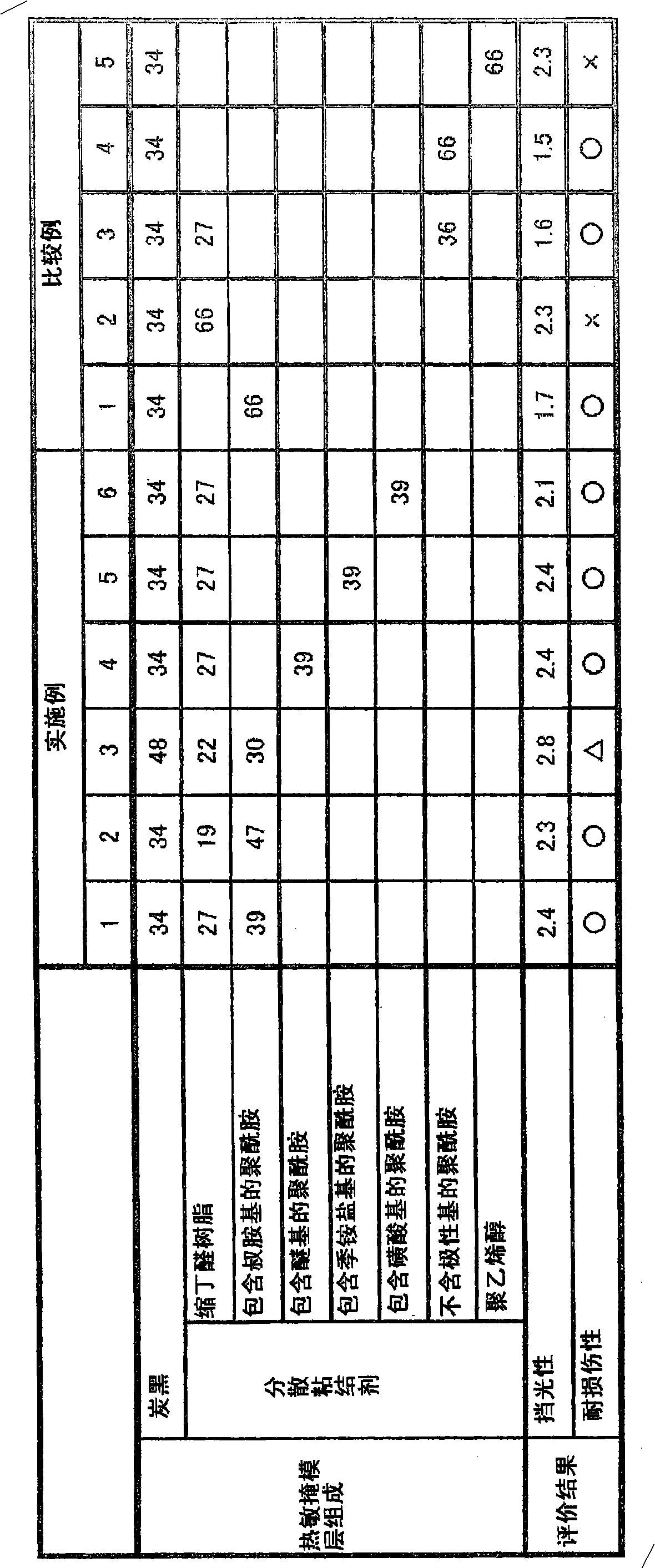

[0043] The present invention is specifically given below through examples, but the present invention is not limited to these examples.

[0044] Preparation of Dispersed Binder

[0045] As the dispersion binder, prepare butyral resin, polyamide containing tertiary amino group, polyamide containing ether group, polyamide containing quaternary ammonium salt group, polyamide containing sulfonic acid group, polyamide containing no polar group polyamide and polyvinyl alcohol. As the butyral resin, BM-5 manufactured by Sekisui Chemical Co., Ltd. was used. As the polyamide containing a tertiary amino group, the polyamide containing a quaternary ammonium salt group, and the polyamide containing a sulfonic acid group, polyamides synthesized as follows are used. Macromelt 6900 produced by Henkel was used as the polyamide not containing a polar group. As the polyvinyl alcohol, GH23 manufactured by Nippon Synthetic Chemicals Co., Ltd. was used.

[0046] Synthesis of polyamides conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com