Gold bonding wire and preparation method thereof

A technology of bonding gold wire and intermediate alloy, which is applied in the field of bonding wire, can solve the problems of affecting the surface cleanliness of the finished wire, limiting the winding length of the take-up shaft, and affecting the use effect of the product, so as to achieve a good low-length arc and prevent a large number of broken wires , Improve the effect of metal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Bonding gold wire of the present invention is prepared according to the following process steps:

[0036] ①Use gold with a purity of 99.99wt% to electrolytically purify high-purity gold with a purity of 99.999wt%. The gold with a raw material purity of 99.99wt% is a commercially available gold material of ordinary purity. This raw material is purified to 99.999wt% by electrolysis. The specific method is:

[0037] The commercially available gold is used as the anode, which is hung on the anode conductive rod, and the inert carbon material is used as the cathode, which is hung on the cathode conductive rod, and the anode and the cathode are kept parallel. Add chloroauric acid solution into the electrolytic cell as the electrolyte, and control the cell pressure at 0.6V during the electrolysis process to ensure the liquid level of the electrolyte (to ensure that 95% of the volume of the cathode sheet is immersed in the electrolyte). The electrolytic gold is washed with pur...

Embodiment 2

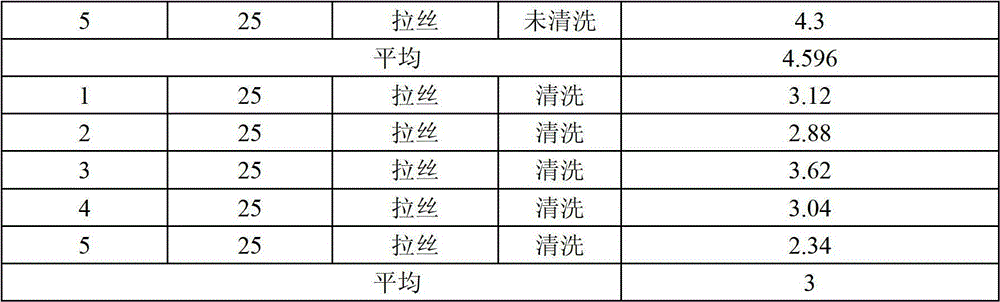

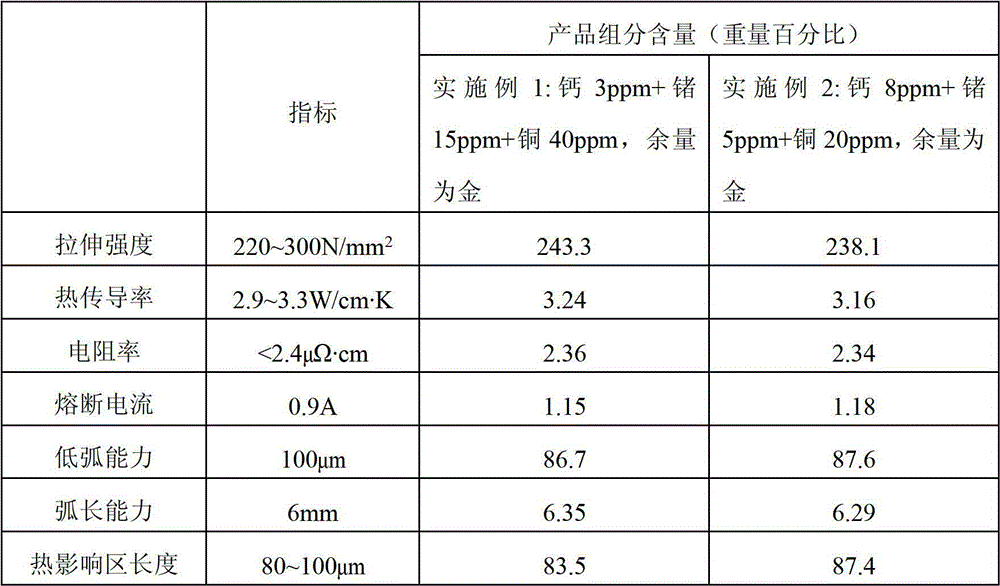

[0060] The method of Example 1 was repeated according to the content of each component specified in Table 2 below, and the performance test parameters are listed in Table 1.

[0061] Table 2 embodiment 1-2 product component content and product performance index

[0062]

[0063] The performance test parameters of each embodiment in Table 2 show that the bonding gold wire of the present invention can meet the target, and has the characteristics of high strength and low arc length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com