Ph-responsive three-dimensional ordered macroporous controlled-release material

A three-dimensional orderly, controlled release technology, applied in non-active ingredients medical preparations, immobilized on/in organic carriers, pharmaceutical formulations, etc., can solve the problems of capsules that are not easy to overcome the burst release effect, low pore volume, etc. , to achieve the effect of wide application value, good controllable release and high graft density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

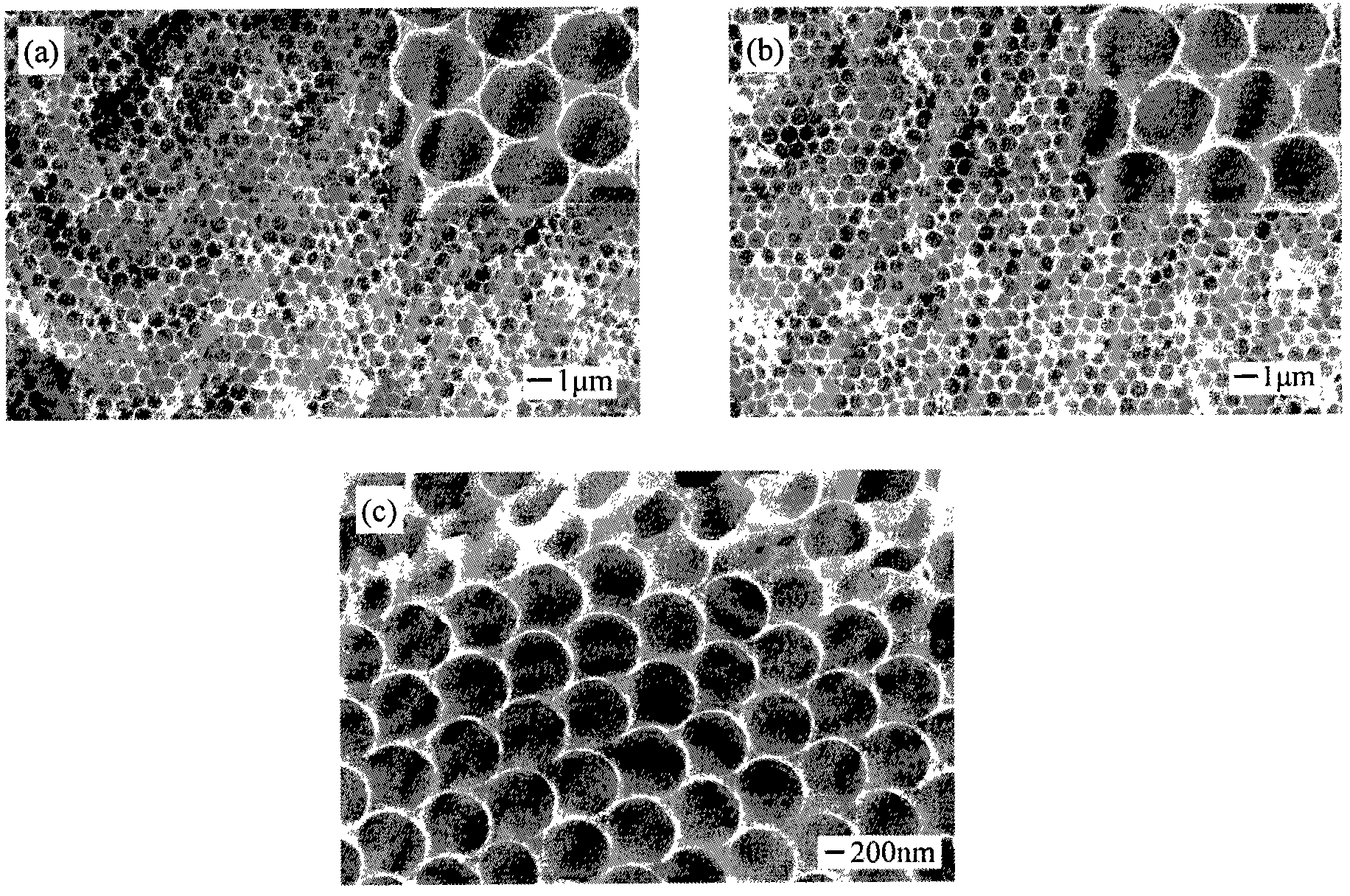

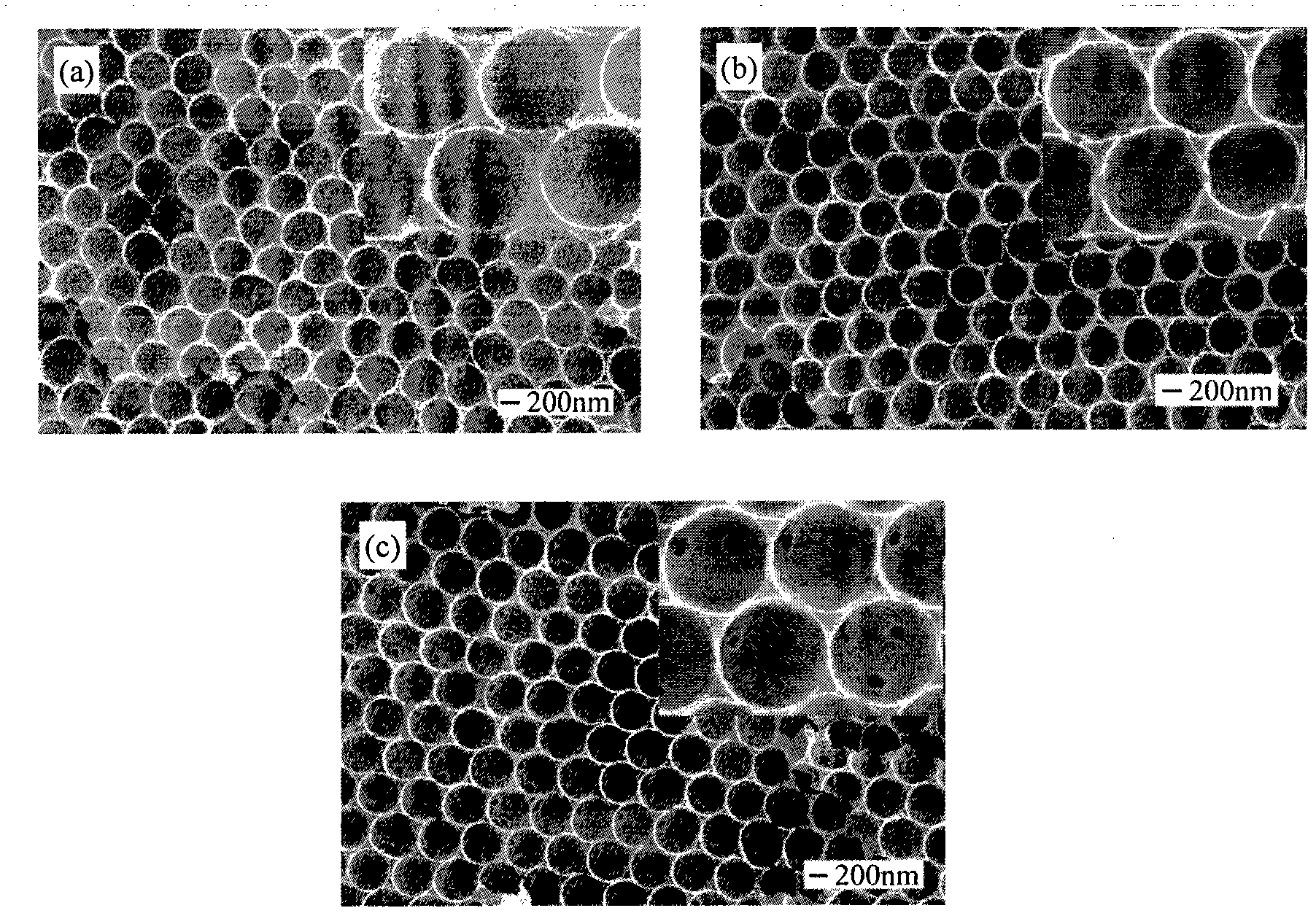

[0028] Preparation of responsive 3DOM CLPS-g-PAA material obtained after hydrolysis of 3DOM CLPS material with an average pore size of 800nm grafted with poly(tert-butyl acrylate) segments.

[0029] (1) Preparation of colloidal crystal templates with an average particle size of 1100 nm

[0030] At room temperature, in a three-necked flask, 11 g of ammonia water with a concentration of 25% by mass, 70 g of absolute ethanol, 6.2 g of distilled water, and 3 g of ethyl orthosilicate were successively added. Stir until the mixed solution becomes a uniform and stable suspension, add an equal amount of ammonia water, absolute ethanol, distilled water and ethyl orthosilicate in the same mass ratio, repeat 3 times, pour the resulting suspension into a beaker, Stand still at room temperature to allow the solvent to volatilize completely to obtain a silica colloidal crystal template, which is placed in a sweet pot, sintered at 400°C in a horse-boiling furnace for 5 hours, and then slow...

Embodiment 2

[0039] Preparation of pH-responsive 3DOM CLPS-g-PMAA material obtained by grafting poly(n-butyl methacrylate) segments with an average pore size of 800 nm after hydrolysis

[0040] (1) Preparation of colloidal crystal templates with an average particle size of 1100 nm

[0041] The preparation method steps of the colloidal crystal template with an average particle diameter of 1100 nm are the same as in Example 1 (1).

[0042] (2) Preparation of three-dimensional ordered macroporous cross-linked polystyrene material with an average pore size of 800nm:

[0043] Average pore diameter is that the preparation method other steps of 800nm three-dimensional ordered macroporous cross-linked polystyrene material are the same as embodiment 1 (2), what adjust is that adding volume is 6ml (5.5g) styrene monomer, 1ml (0.9g) di Vinylbenzene crosslinking agent, 0.03g azobisisobutyronitrile initiator, soak for 1.5 hours, polymerize at 80°C for 32 hours, peel off the polystyrene on the surfac...

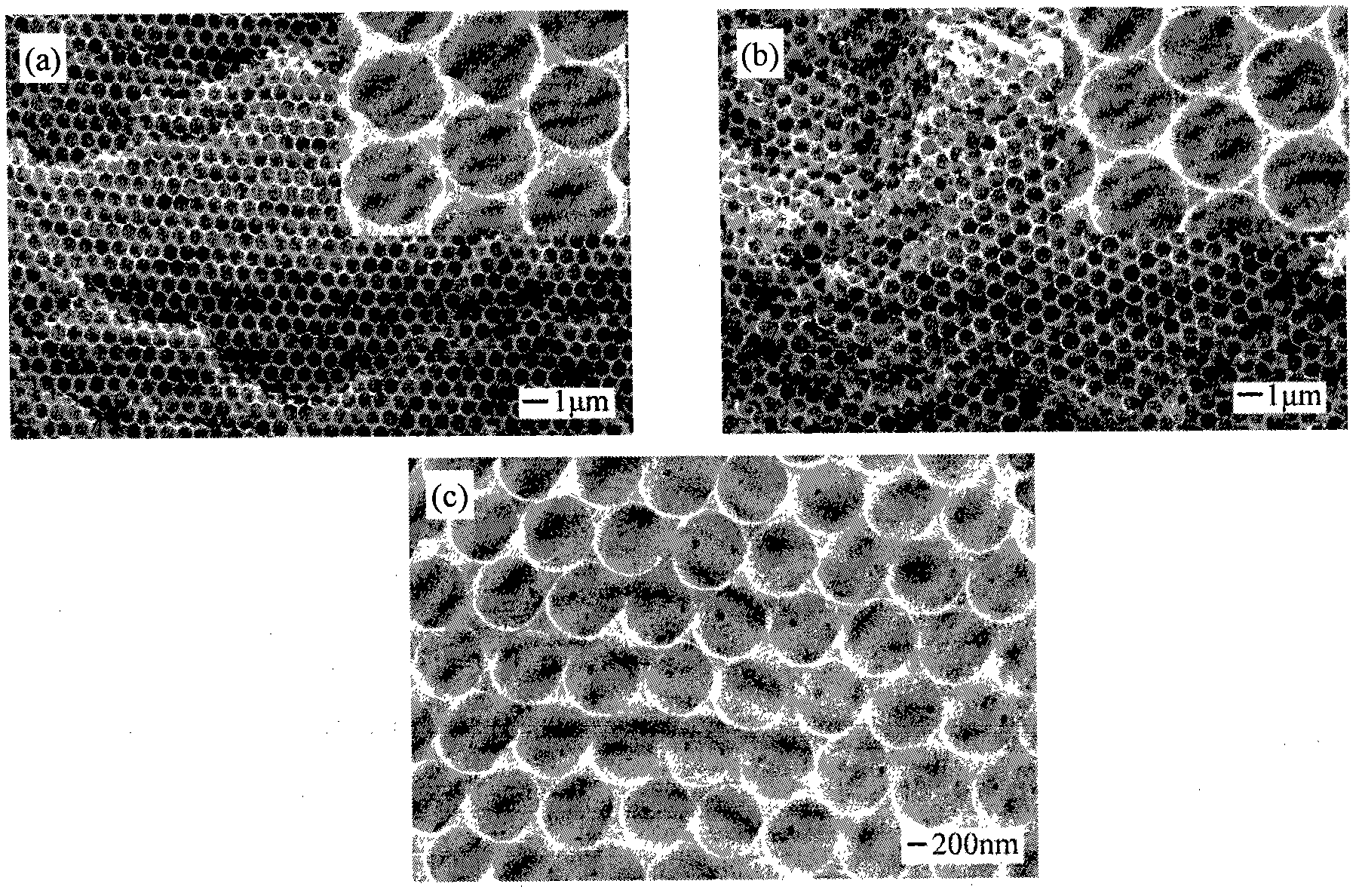

Embodiment 3

[0050] Preparation of pH-responsive 3DOM CLPS-g-P4VP material obtained by grafting poly(4-vinylpyridine) segments on 3DOM CLPS material with an average pore size of 500 nm.

[0051] (1) Preparation of colloidal crystal templates with an average particle size of 660nm

[0052] The other steps of the preparation method of the colloidal crystal template with an average particle diameter of 660nm are the same as in Example 1 (1), and the adjustments are to add 14.3g of ammonia water, 91g of absolute ethanol, 8.06g of distilled water, and 3.9g of distilled water with a concentration of 25%. g tetraethyl orthosilicate, repeated twice to obtain a colloidal crystal template with an average particle diameter of 660 nm.

[0053] (2) Preparation of three-dimensional ordered macroporous cross-linked polystyrene material with an average pore size of 500nm:

[0054] The average pore diameter is 500nm three-dimensional ordered macroporous cross-linked polystyrene material. The other steps o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com