Biological response system for multistage sewage treatment as well as manufacturing method and sewage treatment method

A biological reaction and sewage treatment technology, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

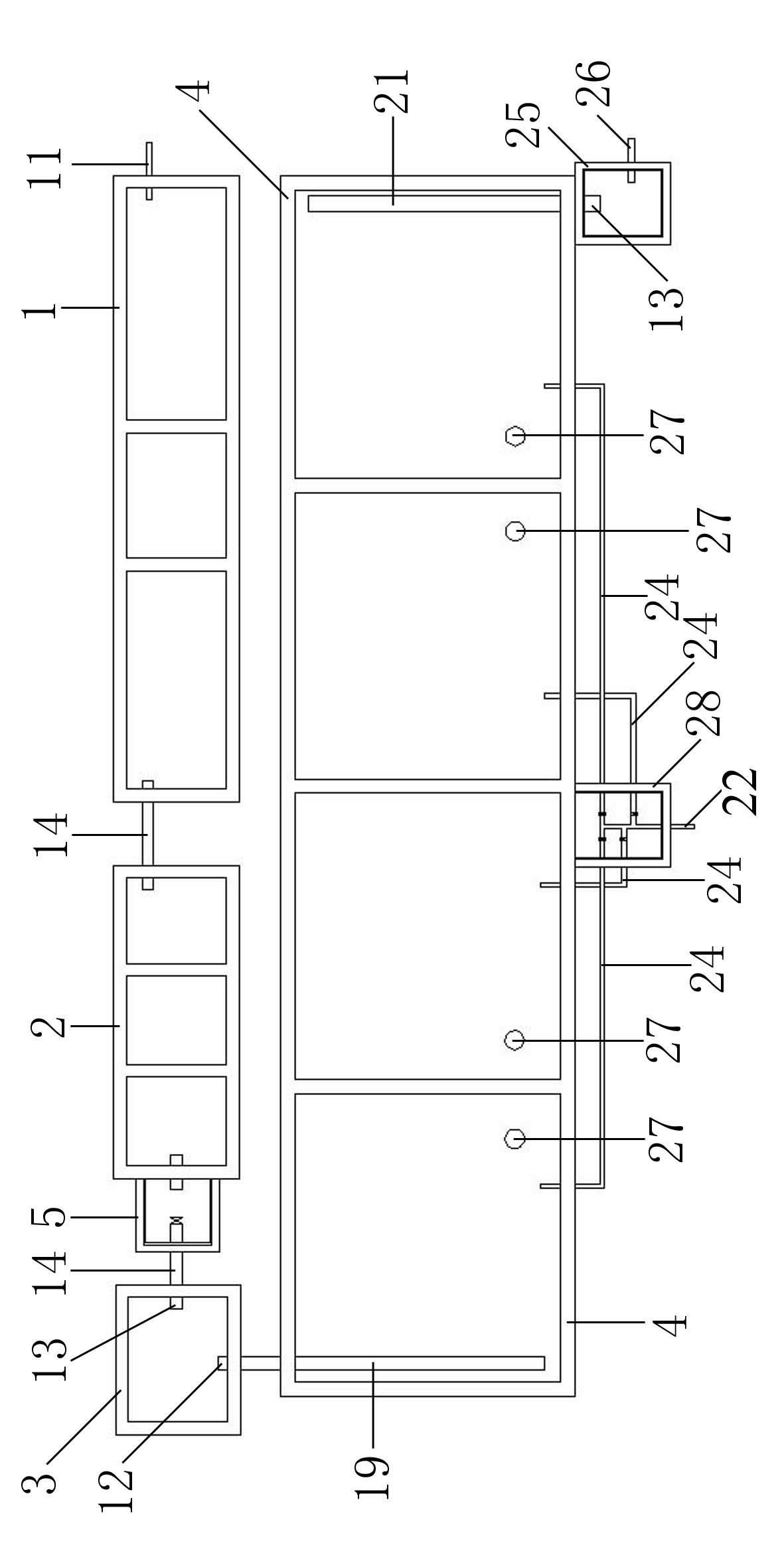

[0142] It consists of a multi-stage sedimentation pretreatment unit (1), a multi-stage hydrolysis acidification treatment unit (2), an aeration and oxygenation treatment unit (3) and a multi-stage subsurface flow wetland treatment unit (4) connected by a pipeline (14). The inflow wetland pool (35), the 2-component decomposition and infiltration wetland pool (36) and the outlet wetland pool (37) of the multi-stage subsurface flow wetland treatment unit (4) are arranged in sequence, and one side of the multi-stage subsurface flow wetland treatment unit (4) The multi-stage sedimentation pretreatment unit (1), the multi-stage hydrolytic acidification treatment unit (2) and the aeration and oxygenation treatment unit (3) are arranged side by side in sequence, and are connected by pipelines (14), such as figure 1 shown.

Embodiment 2

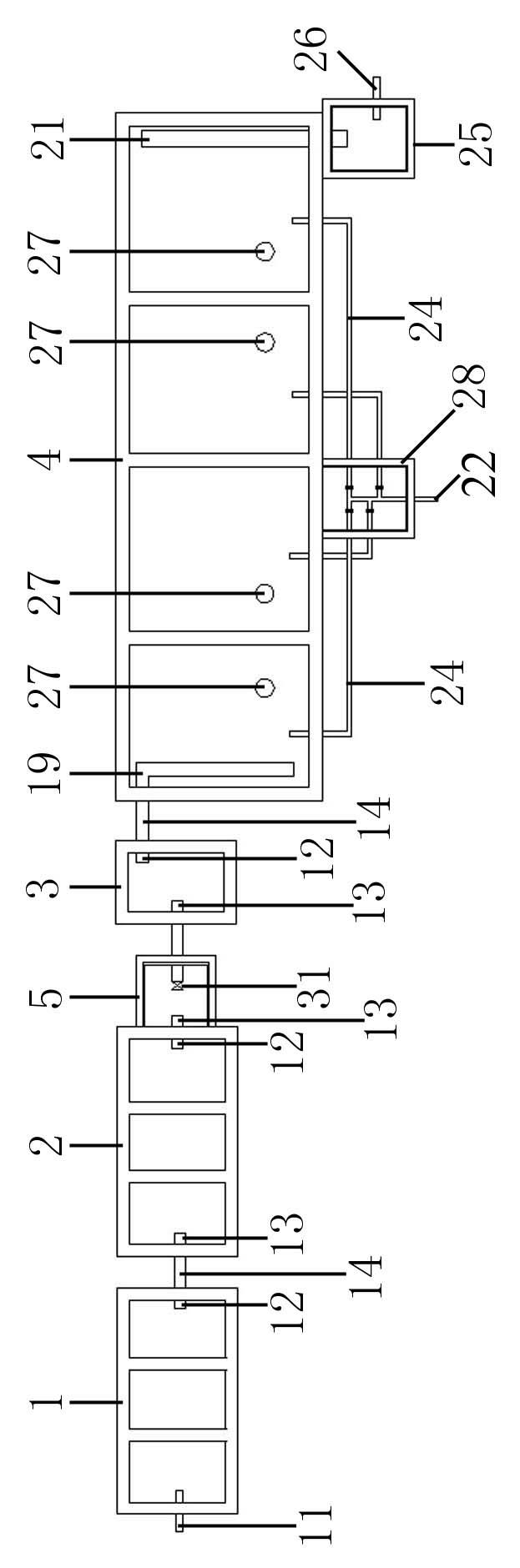

[0144] The multi-stage sedimentation pretreatment unit (1), the multi-stage hydrolytic acidification treatment unit (2), the aeration and aeration treatment unit (3) and the multi-stage subsurface flow wetland treatment unit (4) are arranged in sequence and connected to each other through the pipeline (14). connection, such as figure 2 shown.

Embodiment 3

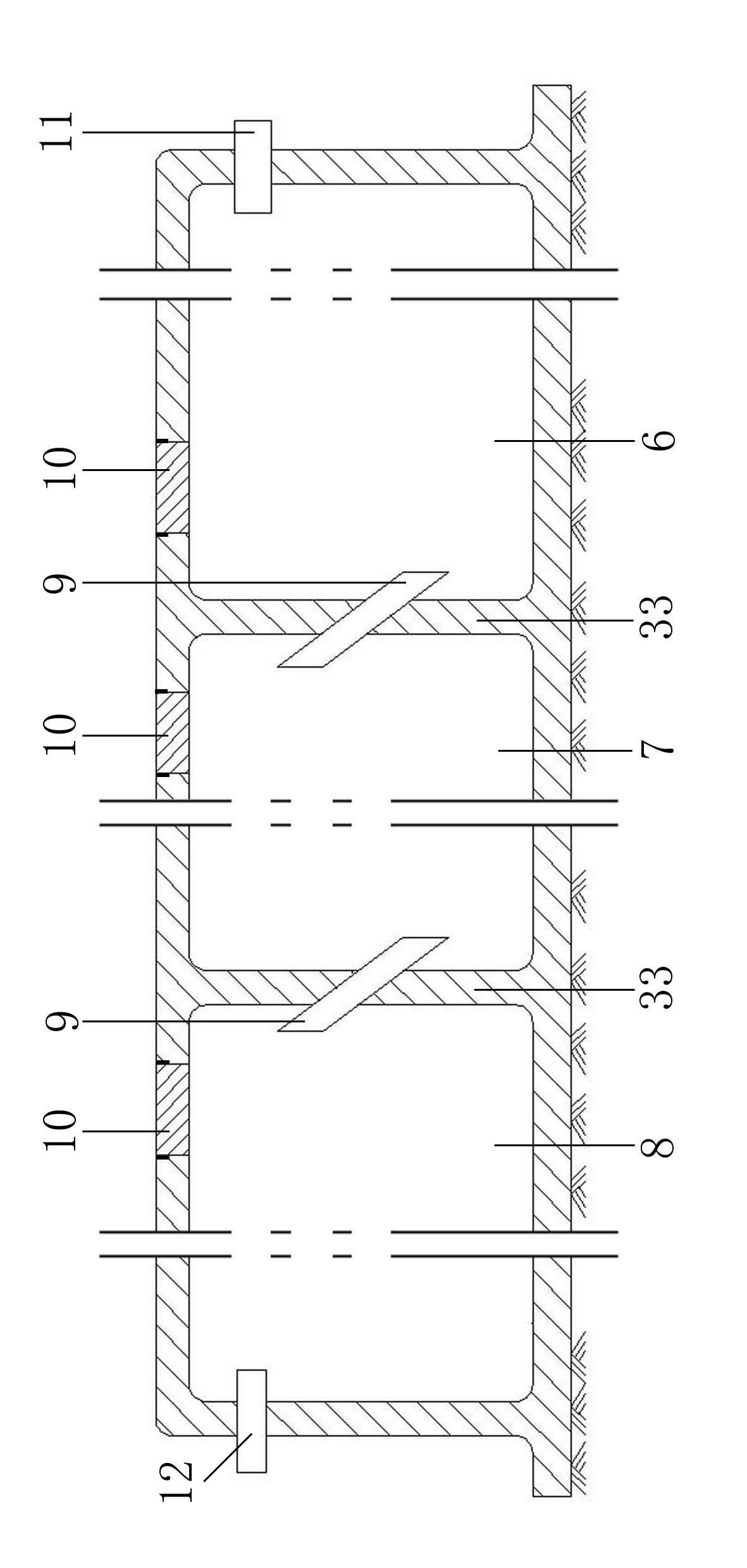

[0146]The multi-stage sedimentation pretreatment unit (1) is a closed box, and the box is divided into at least 3 spaces by a partition (33), and the spaces are respectively the sedimentation and decomposition tank (6), the fermentation sedimentation tank (7) and the storage tank (8), a closed slag removal port (10) is arranged on the top of each space, and a sealing cover is installed on the slag removal port (10), forming a closed operating space.

[0147] The upper part of the wall of the sedimentation decomposition tank (6) on the side of the multi-stage sedimentation pretreatment unit (1) is provided with a sewage inlet (11), and the sewage inlet (11) is introduced into the sewage source through the pipeline (14), and the sewage inlet ( 11) A gate valve is set on the pipeline (14) to control the inflow of the sewage source, and the sewage source is domestic sewage and aquaculture wastewater. Set at least one inclined overflow pipe (9) in the middle of the partition (33) b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com