NiCrAIY coating for nickel base high temperature alloy and preparation method thereof

A nickel-based superalloy and coating technology, applied in metal material coating process, coating, solid-state diffusion coating, etc. The effect of low production cost, improved service life, and improved thermal corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

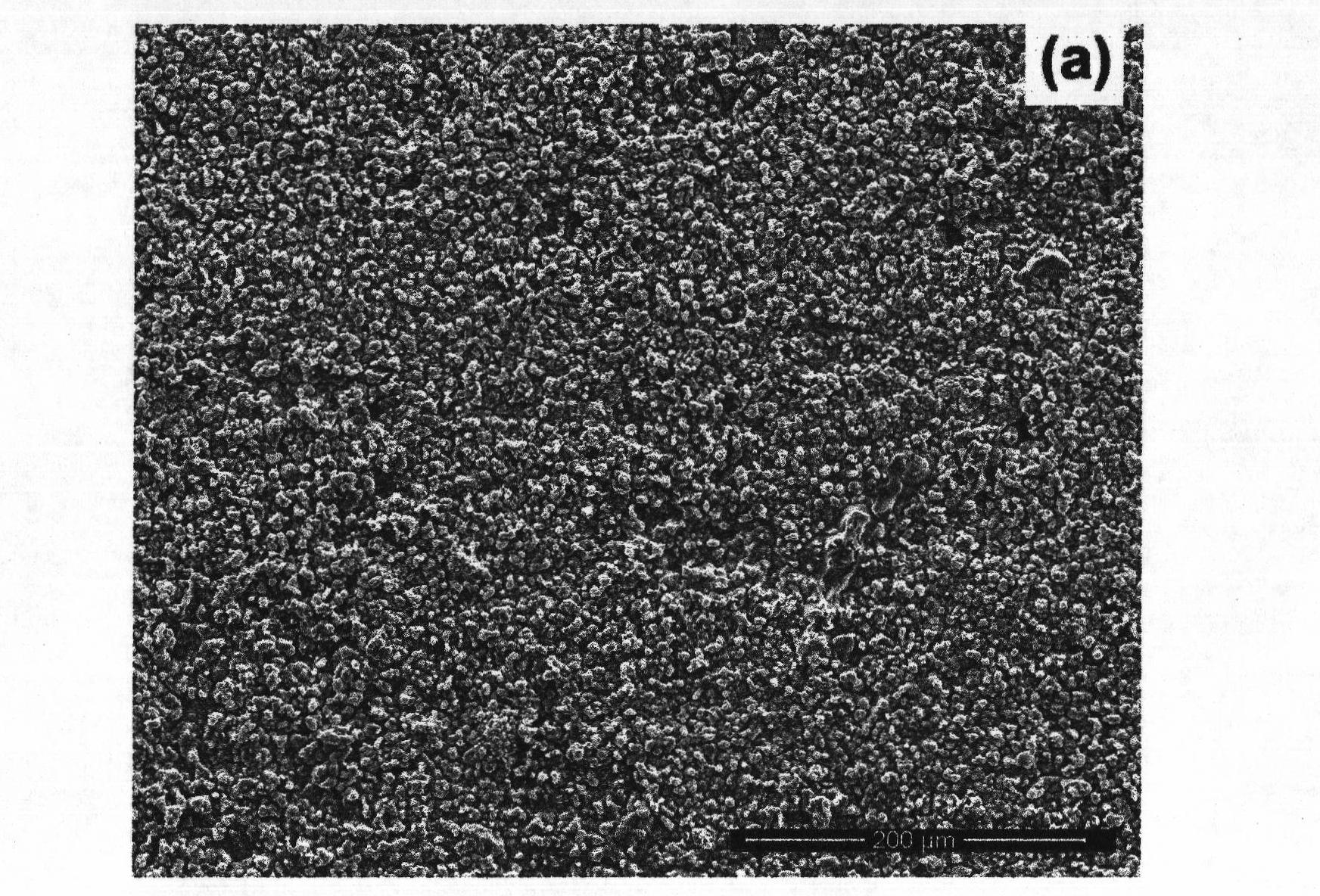

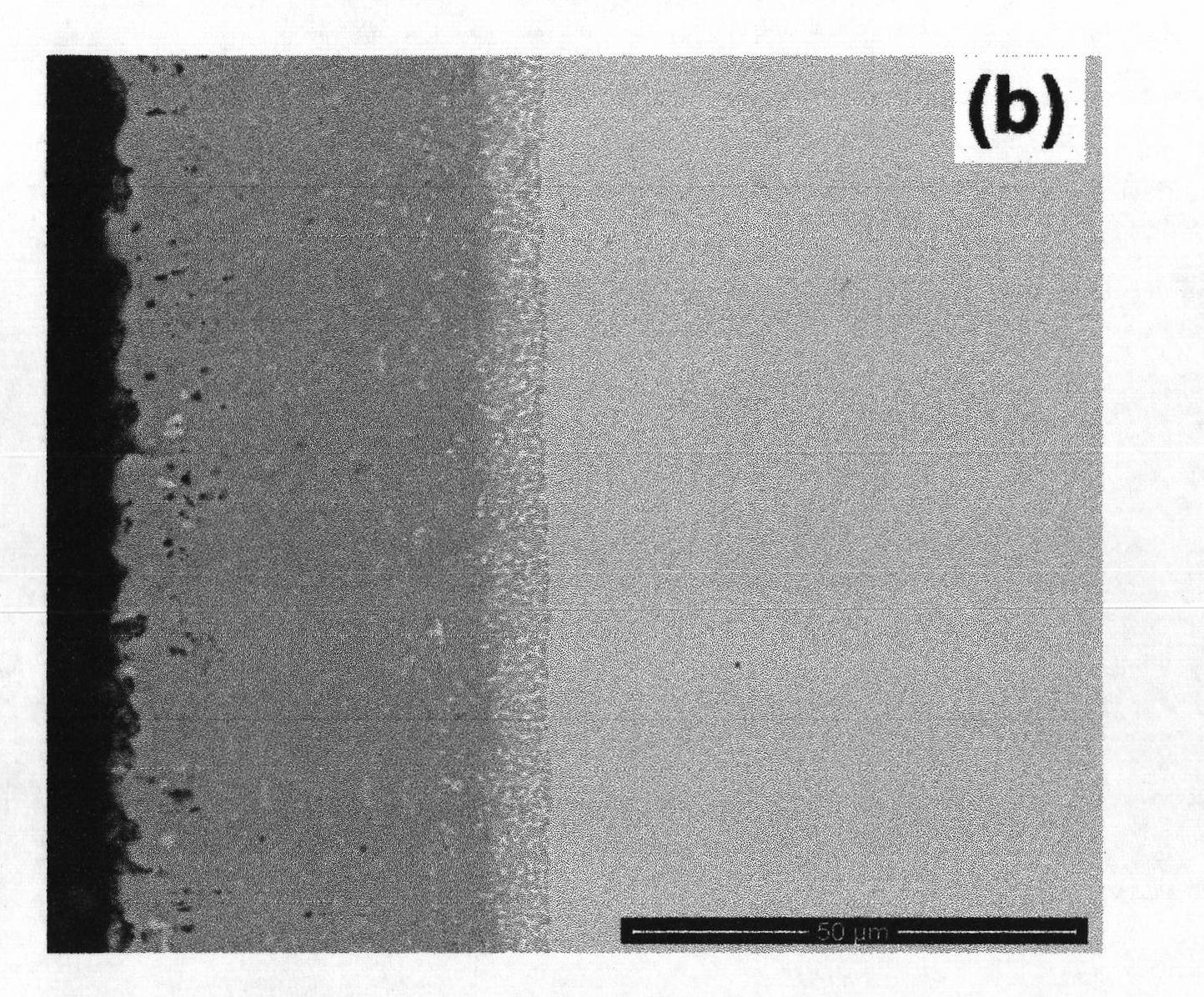

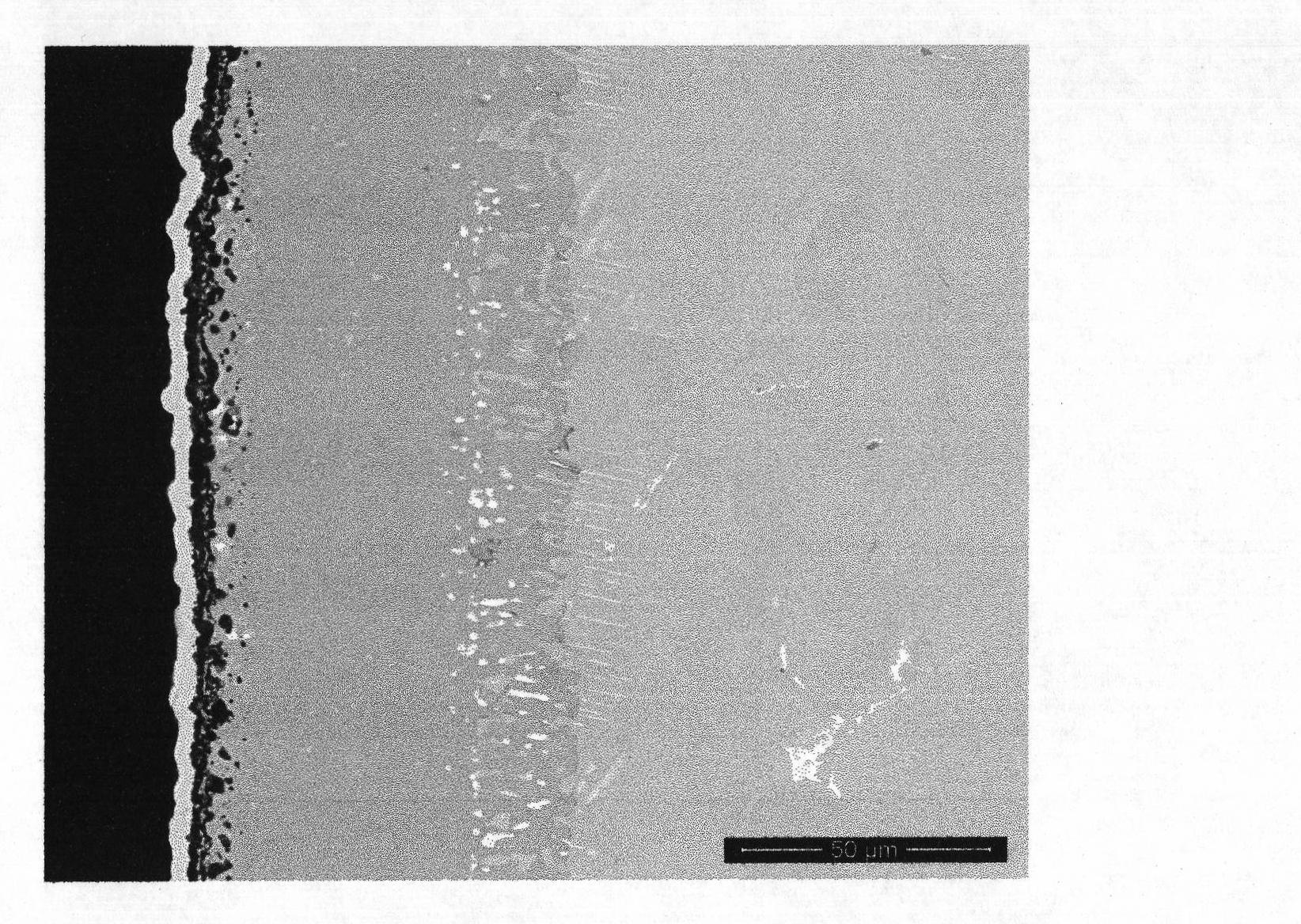

[0043] NiCrAlY co-infiltration coating was prepared by thermal diffusion method with Ni-based superalloy K417G as substrate. The implementation process is as follows: First, remove the oxide layer on the surface of the superalloy, grind it to 800# with SiC sandpaper to obtain a flat surface, clean it with acetone and ultrasonic waves, and dry it. The treated substrate was sprayed with Y-rich slurry (20% Y (wt)), the slurry thickness was 0.8mm, and dried at 100°C. Secondly, the parts that have been sprayed with Y slurry are embedded in Cr-containing powder, and the powder components are Cr, Ni, Al 2 o 3 and NH 4 Cl. Diffusion at 1050°C for 1 hour in an argon-protected atmosphere. Finally, put the parts containing Y-Cr coating into FeAl powder and NH 4 In the mixed powder of Cl, in the atmosphere of argon protection, diffuse at 1000°C for 4 hours to obtain NiCrAlY co-infiltration coating. The coating microstructure is as figure 1 shown. After 300 hours of high temperatur...

Embodiment 2

[0045] NiCrAlY co-infiltration coating was prepared by thermal diffusion method with Ni-based superalloy K438G as substrate. Implementation technique is as embodiment 1. After 300 hours of high temperature oxidation test at 1000℃, the weight gain of the coating is 0.88mg / cm 2 , a uniform aluminum oxide film was formed on the surface. The coating is coated with 25%NaCl+75%Na 2 SO 4 (wt%) salt, the amount of salt applied is 1.0-1.5mg / cm 2 , after 900 ℃ hot corrosion test for 100h, a dense aluminum oxide film was formed on the surface, and the remaining 55% of the coating remained unchanged.

Embodiment 3

[0047] NiCrAlY co-infiltration coating was prepared by thermal diffusion method with Ni-based superalloy GH4037 as substrate. Implementation technique is as embodiment 1. After 1000℃ high temperature oxidation test for 300 hours, the weight gain of the coating is 0.95mg / cm 2 , a uniform aluminum oxide film was formed on the surface. The coating is coated with 25%NaCl+75%Na 2 SO 4 (wt%) salt, the amount of salt applied is 1.0-1.5mg / cm 2 , after 900 ℃ hot corrosion test for 100h, a dense aluminum oxide film was formed on the surface, and the remaining 70% of the coating remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gain weight | aaaaa | aaaaa |

| Gain weight | aaaaa | aaaaa |

| Gain weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com