EVA (ethylene vinyl-acetate copolymer) adhesive film capable of simplifying packaging structure of solar battery

A technology of solar cells and packaging structures, which is applied in circuits, adhesives, photovoltaic power generation, etc., can solve the problems of not simplifying the packaging structure of solar cells, the performance can not fully meet the requirements, and the poor bonding performance with the polyester layer, etc., to improve the photoelectricity Conversion efficiency, good anti-ultraviolet and aging performance, enhanced reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

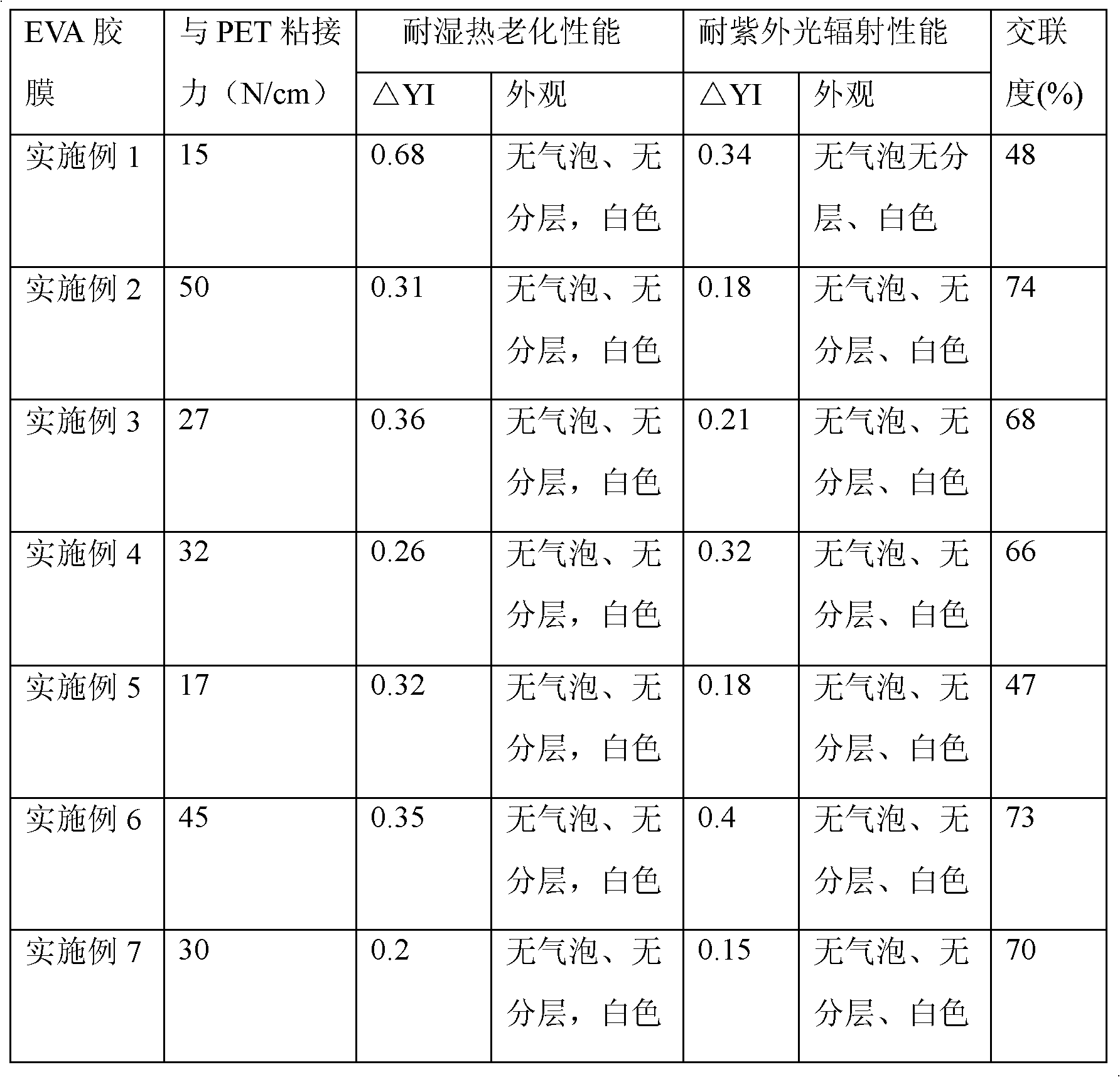

Embodiment 1

[0037] 100kg vinyl acetate content is 14%, and melt index is 15g / 10min EVA raw material, add 0.5kg cross-linking agent tert-butyl peroxide 2-ethylhexyl carbonate, 0.5kg compatibilizer glycidyl methacrylate , 0.5kg antioxidant tris(nonylphenyl) phosphite, 0.05kg light stabilizer N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1, 6-hexamethylenediamine, 1kg of rutile titanium dioxide with an average particle size of 30nm, 0.5kg of tackifier triaminopropyltrimethoxysilane, mixed uniformly through a mixer, put into a casting machine, at 80°C, plasticized Chemical extrusion, stretching, traction, and winding to make an EVA film with a thickness of about 0.1mm.

Embodiment 2

[0039] 100kg vinyl acetate content is 14%, and melt index is 15g / 10min EVA raw material, add 1.0kg cross-linking agent tert-butyl peroxide 2-ethylhexyl carbonate, 0.5kg compatibilizer glycidyl methacrylate , 0.5kg antioxidant tris(nonylphenyl) phosphite, 0.05kg light stabilizer N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1, 6-hexamethylenediamine, 10kg of rutile titanium dioxide with an average particle size of 100nm, and 1.5kg of tackifier triaminopropyltrimethoxysilane were mixed uniformly by a mixer, put into a casting machine, and passed through plastic at 80°C. Chemical extrusion, stretching, traction, and winding to make an EVA film with a thickness of about 0.5mm.

Embodiment 3

[0041] It is 14% at 100kg vinyl acetate content, and melt index is the EVA raw material that adds 0.8kg crosslinking agent tert-butyl peroxide 2-ethylhexyl carbonate in the EVA raw material of 15g / 10min, 2kg compatibilizer glycidyl methacrylate, 1kg antioxidant tris(nonylphenyl)phosphite, 0.2kg light stabilizer N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,6- Hexamethylenediamine, 1kg of rutile titanium dioxide with an average particle size of 1000nm, 0.5kg of tackifier triaminopropyltrimethoxysilane, mixed uniformly by a mixer, put into a casting machine, and plasticized at 80°C Extrude, stretch, pull, and roll to make an EVA film with a thickness of about 0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com