Forge welding method for manufacturing wind power main shaft

A wind power spindle and forging welding technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems that cannot meet the design requirements of large wind power spindles, the performance of the forging body is quite different, and the structure density of the spindle is low. The effect of improving material utilization, improving operation stability and safety, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

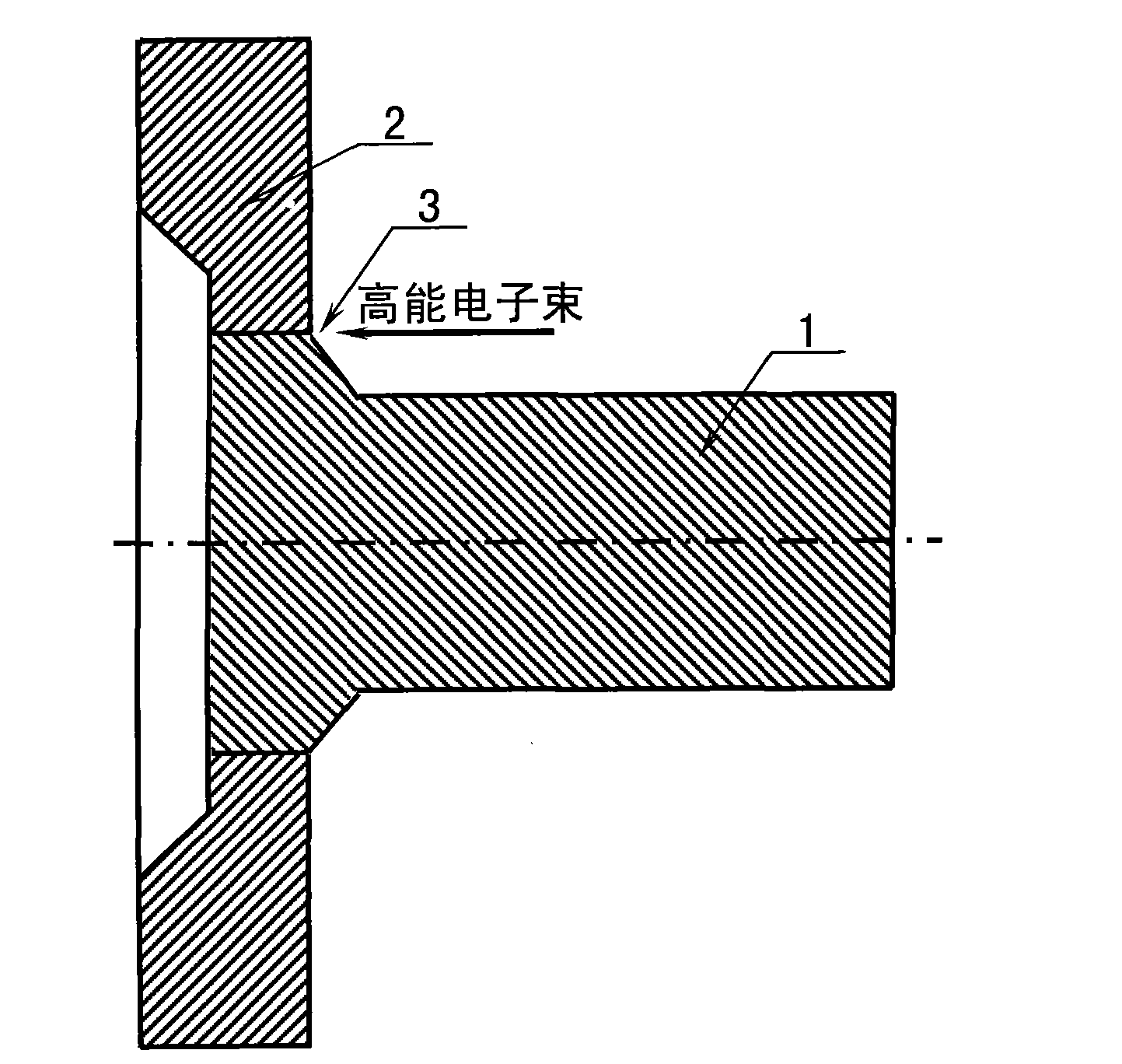

[0022] Example 1. combine figure 1 , figure 2 , image 3 and Figure 4 Taking the manufacture of a 1.5ΩW wind power main shaft as an example by implementing high-energy electron beam welding on the shaft side or the flange side along the axial direction from the wind power main shaft in the present invention to manufacture a 1.5ΩW wind power main shaft as an example, the specific steps are as follows:

[0023] Step 1, forging and welding structure design. According to the requirement that the weight of each split structural part of the wind power spindle forging is less than the tonnage of the forging equipment, forging equipment that meets the design requirements of forging and welding structures and medium-pressure or high-voltage high-energy electron beam deep penetration welding with a weld penetration depth of δ100mm is adopted machine, determine that the wind power spindle forging and welding split structural parts are Φ1600mm hollow flange (2) and Φ750mm connecting...

Embodiment 2

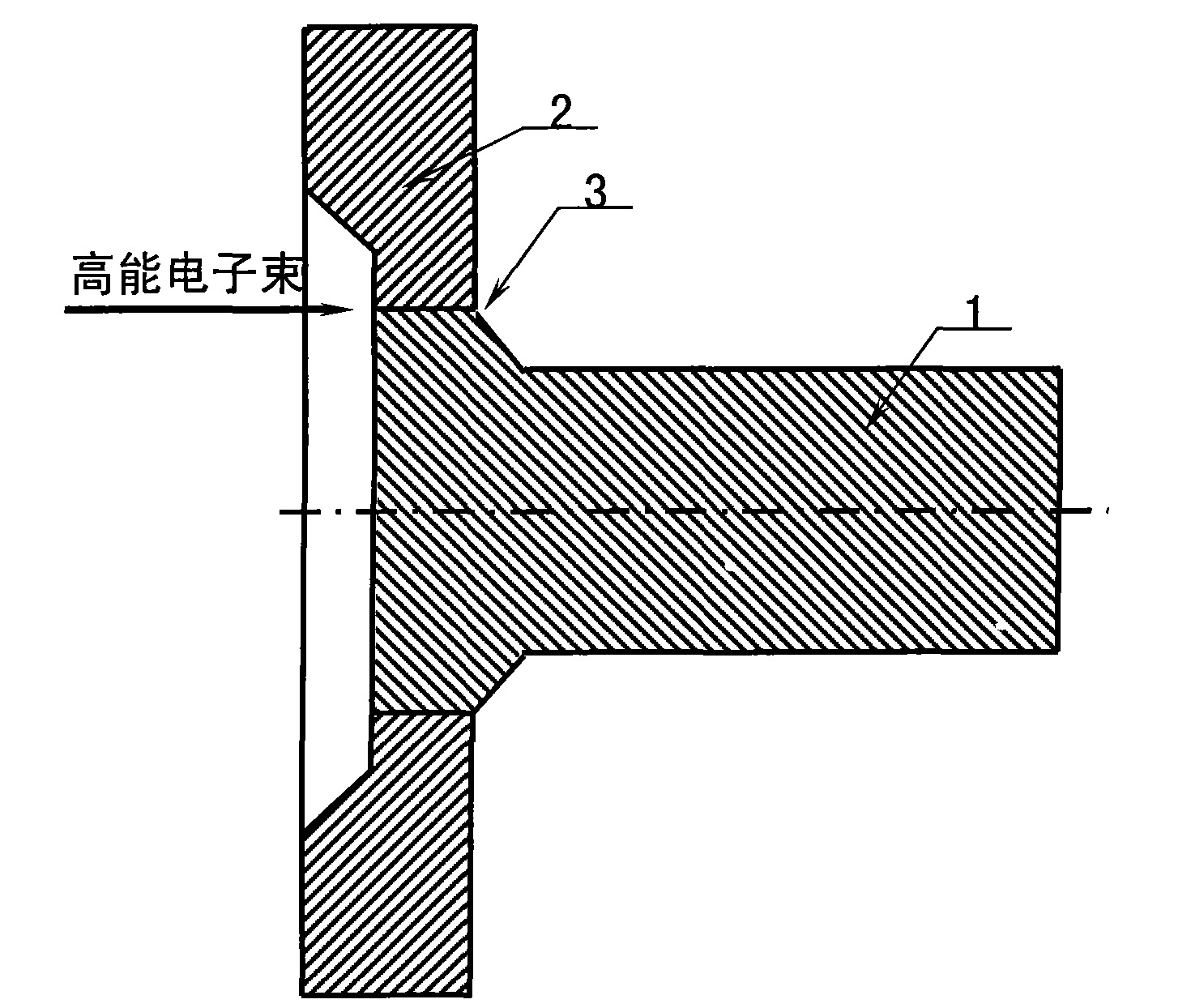

[0030] Example 2. combine figure 1 and Figure 5 , taking the manufacture of a 1.0ΩW wind power main shaft by high-energy electron beam welding from a direction perpendicular to the axis of the wind power main shaft as an example, the specific steps are as follows:

[0031] Step 1, forging and welding structure design. According to the requirement that the weight of each split structural part of the wind power main shaft forging and welding is less than or equal to the tonnage of the forging equipment, forging equipment that meets the design requirements of the forging and welding structure and a medium-pressure or high-voltage high-energy electron beam deep melting with a weld penetration depth of δ193mm are adopted. For the welding machine, it is determined that the wind power spindle forging and welding split structural parts are Φ1200mm solid flange (5) and Φ380mm end shaft (4). The depth of penetration guarantees the penetration of the end shaft portion of Φ380 mm to for...

Embodiment 3

[0038] Example 3. combine figure 1 and Figure 6 , taking the wind power main shaft of the split structure of the three components proposed by the present invention and implementing high-energy electron beam deep penetration welding twice to manufacture a 2.5ΩW wind power main shaft as an example, the specific steps are as follows:

[0039] Step 1, forging and welding structure design. According to the requirement that the weight of each split structural part of the wind power main shaft forging is less than the tonnage of the forging equipment, the forging equipment that meets the design requirements of the forging and welding structure and the weld penetration depth of δ180mm and 250mm medium-voltage or high-voltage high-energy electron beam depth are adopted. For the fusion welding machine, determine the forged and welded split structural parts of the wind power main shaft as the Φ1800mm hollow flange (2), the mandrel (6) and the end shaft (4) with a diameter less than or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com