Method for preparing reverse osmosis composite membrane containing modified nano-zeolite molecular sieve

A technology of reverse osmosis composite membrane and nano-zeolite, which is applied in the field of reverse osmosis composite membrane preparation, can solve the problems affecting the excellent performance of inorganic particles, the difficulty of controlling particle dispersion, and affecting the performance of composite membranes, so as to avoid the increase of interface defects and improve Separation performance, effect of weakening interface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] To 116ml of toluene, add 0.1g of LTA nano-zeolite molecular sieve with a particle size of 60nm and 0.005g of methyltrimethoxysilane, heat the reaction solution to 100°C, and the modification reaction time is 5h. After the reaction is completed, stop and Cool, filter, and wash with ethanol until no modifying reagent remains in the eluent, and then bake the filter cake in a vacuum oven at 100° C. for 24 hours to prepare a surface-modified LTA nano-zeolite molecular sieve.

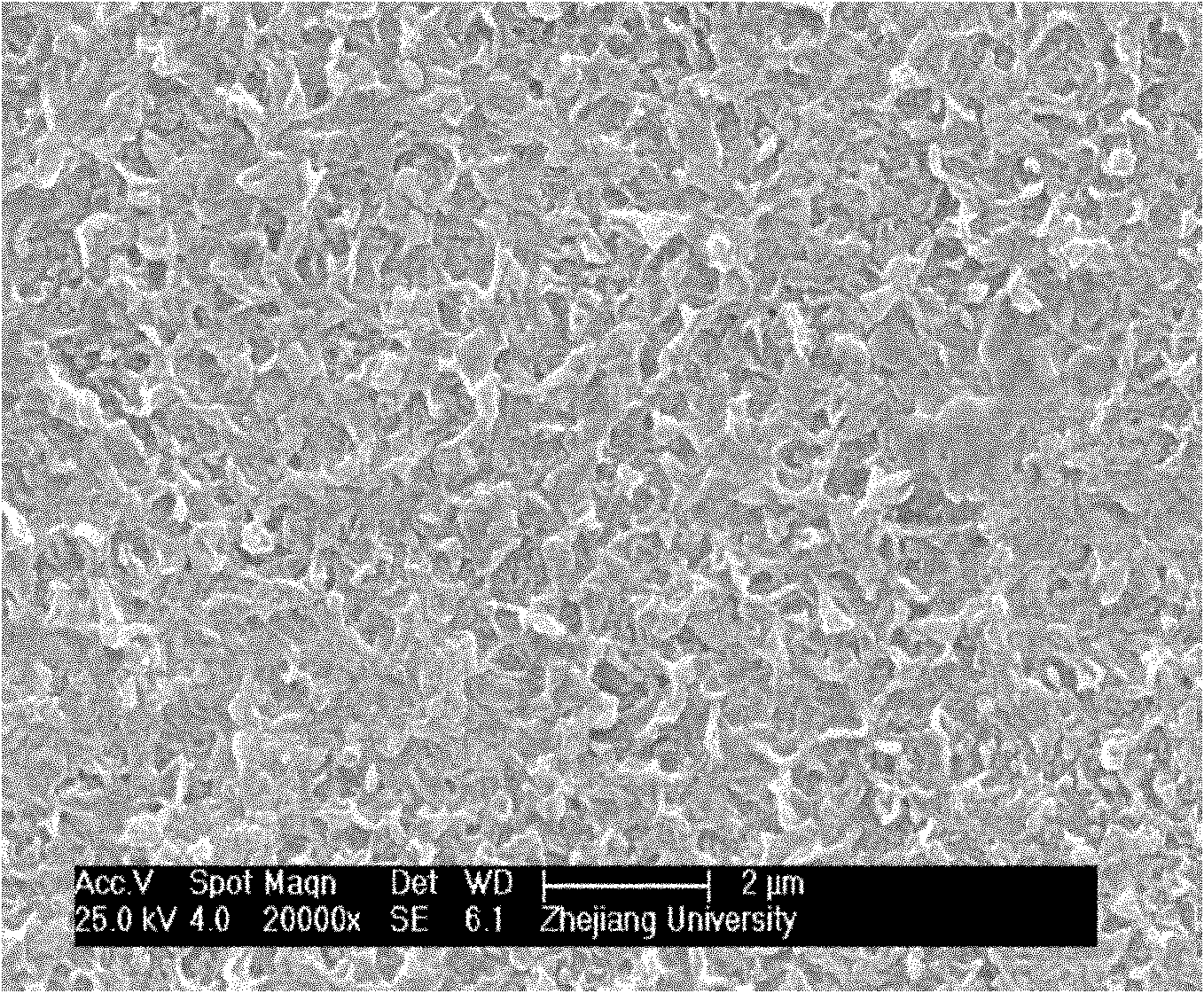

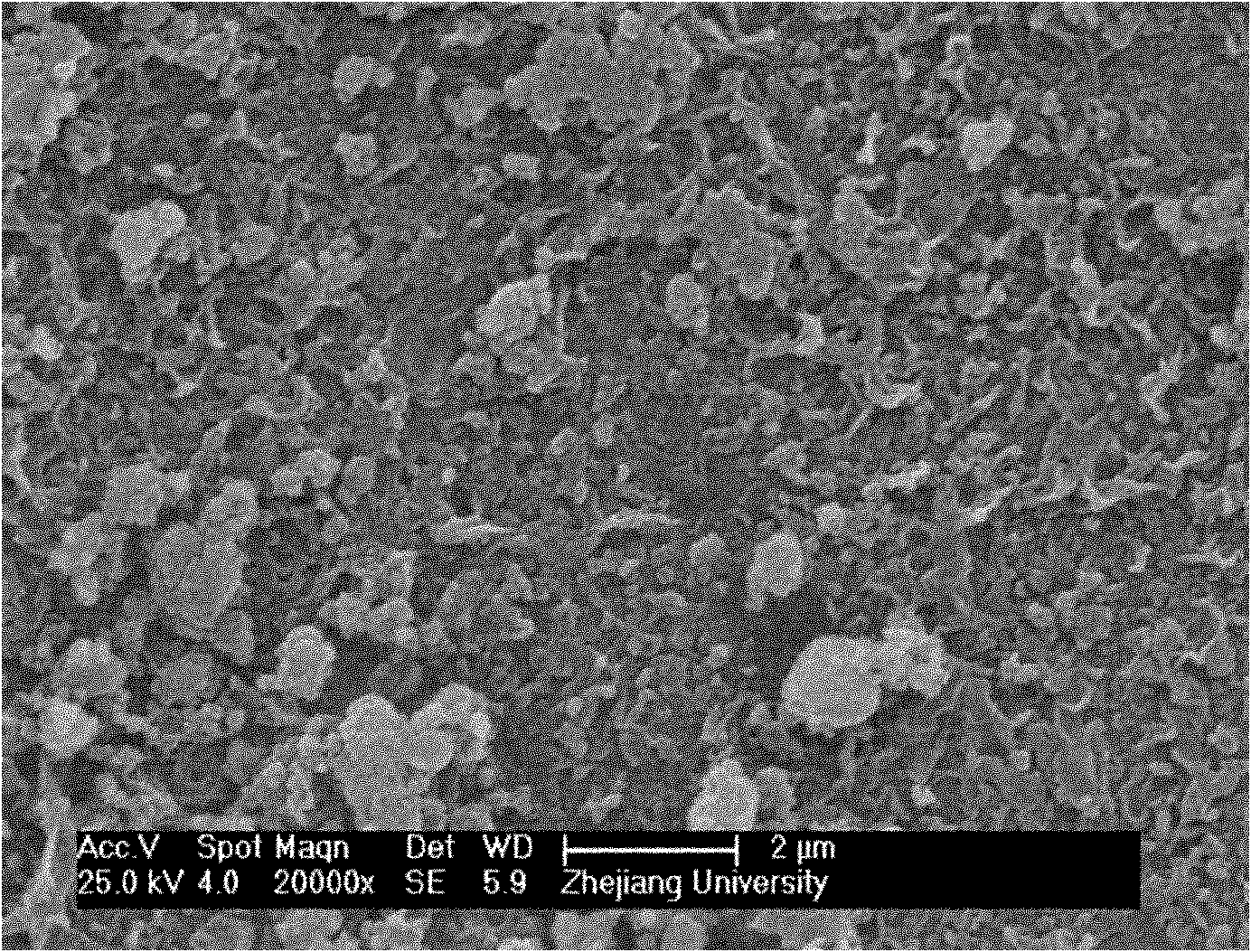

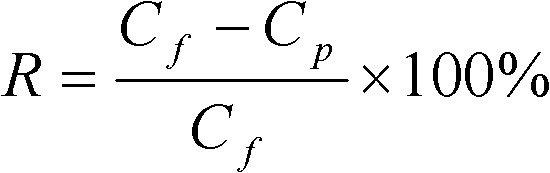

[0029] Dispersing the surface-modified LTA-type nano-zeolite molecular sieve prepared into 50ml of n-hexane solution of trimesoyl chloride with a concentration of 0.1% by weight to ensure that the surface-modified LTA-type zeolite by weight concentration is 0.006%, Ultrasound treatment at room temperature for 10 minutes to obtain the mixture; 1g of the polysulfone porous ultrafiltration membrane with an average pore diameter of 30 nanometers was directly immersed in 100ml of m-phenylenediamine aqueous s...

Embodiment 2

[0031] To 58ml of toluene, add 0.075g of LTA nano-zeolite molecular sieve with a particle size of 70nm and 0.005g of propyltrimethoxysilane, heat the reaction solution to 110°C, and the modification reaction time is 10h. After the reaction is completed, stop and After cooling, the obtained product is filtered, washed with ethanol until no modifying reagent remains in the eluent, and then baked in a vacuum oven at 100°C for 24 hours to prepare a surface-modified LTA nano-zeolite molecular sieve.

[0032]Disperse the surface-modified LTA nano-zeolite molecular sieve prepared into 50ml of n-hexane solution with trimesoyl chloride at a concentration of 0.3% by weight to ensure that the surface-modified LTA-type zeolite molecular sieve has a weight percent concentration of 0.012% , sonicated at room temperature for 20 minutes to obtain the mixture; 1g of the polysulfone porous ultrafiltration membrane with an average pore diameter of 30 nanometers was directly immersed in 100ml of m...

Embodiment 3

[0034] To 30ml of toluene, add 0.05g of LTA nano-zeolite molecular sieve with a particle size of 80nm and 0.005g of octyltrimethoxysilane, heat the reaction solution to 120°C, and the modification reaction time is 15h. After the reaction is completed, stop and After cooling, the obtained product is filtered, washed with ethanol until no modifying reagent remains in the eluent, and then baked in a vacuum oven at 100°C for 24 hours to prepare a surface-modified LTA nano-zeolite molecular sieve.

[0035] Dispersing the surface-modified LTA-type nano-zeolite molecular sieve prepared into 50ml of n-hexane solution of trimesoyl chloride with a concentration of 0.5% by weight, ensuring that the surface-modified LTA-type zeolite molecular sieve by weight concentration is 0.025%, Ultrasound treatment at room temperature for 10 minutes to obtain the mixture; 1g of the polysulfone porous ultrafiltration membrane with an average pore diameter of 30 nanometers was directly immersed in 100ml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com