Preparation method for tissue engineering scaffold material

A technology of tissue engineering scaffold and sucrose, which is applied in medical science, prosthesis, etc., can solve the problems of poor connectivity between pores and high obturator rate, and achieve the effects of low obturator rate, increased porosity, and wide connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the present invention discloses a preparation method of a tissue engineering scaffold material, which is characterized in that it comprises:

[0031] Step a) mixing sucrose fibers with particles to obtain a mixture, said particles being sucrose particles and / or salt particles;

[0032] Step b) mixing the mixture obtained in step a) with a degradable polymer and a solvent, and then freezing to obtain a compound, and removing the compound and solvent obtained in step a) from the compound to obtain a tissue engineering scaffold material.

[0033] In step a) of the present invention, the sucrose fiber is preferably prepared according to the following method:

[0034] Spinning sucrose to obtain sucrose fibers;

[0035] The sucrose fibers are sheared.

[0036] The above-mentioned spinning method is preferably a melt spinning method, a solution spinning method, a melt spinning method, an electrospinning method, a disk spinning method or a screw extrusion me...

Embodiment 1

[0045] Making sucrose into sucrose fibers with a diameter of 50 μm by spinning disk spinning method to provide sucrose particles with a particle size of 300 μm;

[0046] Dissolve polylactide-glycolide (PLGA) in acetone at a mass volume ratio of 5% g / ml, and stir magnetically to obtain a polylactide-glycolide solution;

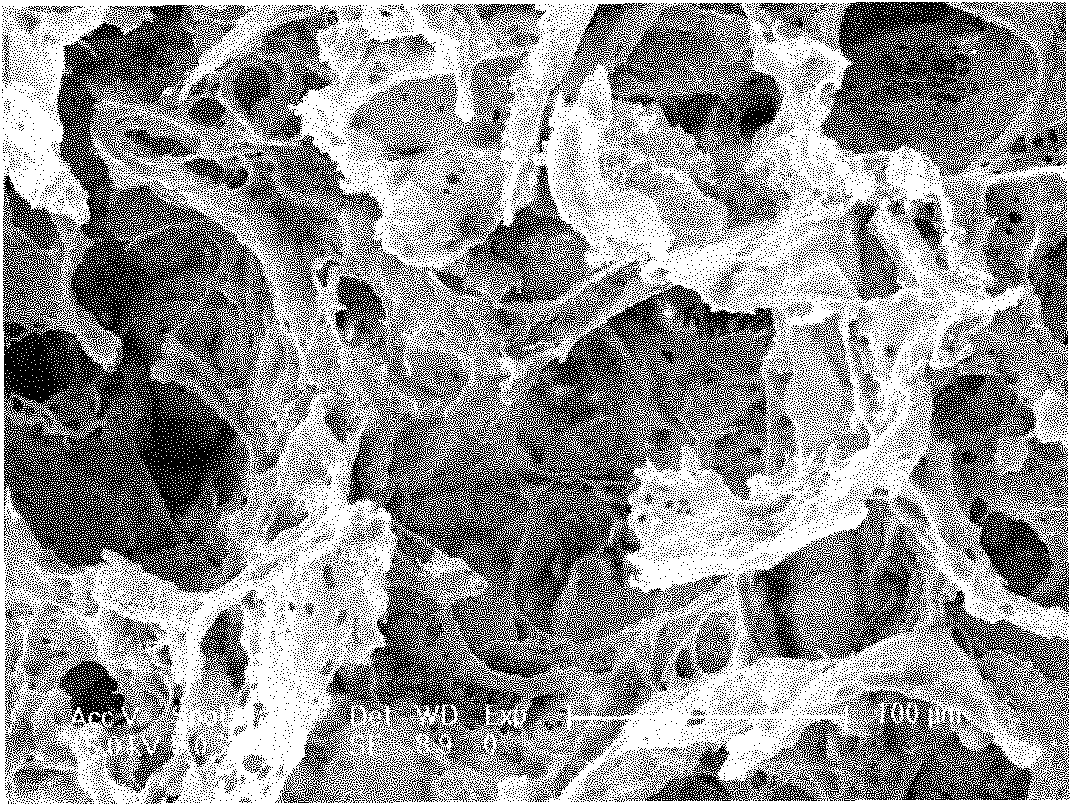

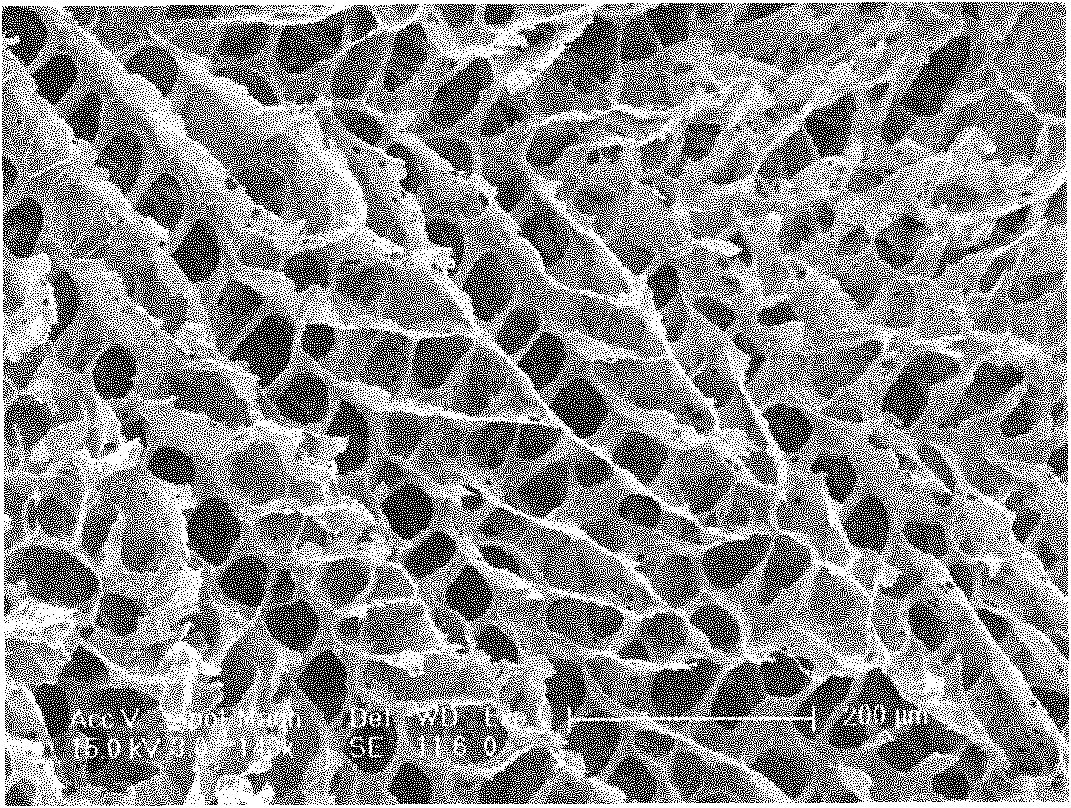

[0047]The sucrose fiber is shredded, mixed with the sucrose particles at a weight ratio of 1:1, and then mixed with the polylactide-glycolide solution, and the weight ratio of the PLGA to the sucrose fiber and particles is 1:2:2, stir evenly, freeze at -20°C, then use a vacuum pump to sublimate acetone in a 4°C freezer to obtain a complex, put the obtained complex into distilled water, and constantly replace the distilled water to make sucrose fiber and sucrose The particles are dissolved and dried to obtain tissue engineering scaffold materials. The scanning electron microscope picture of the tissue engineering scaffold material prepared in this embodiment is...

Embodiment 2

[0049] Making sucrose into sucrose fibers with a diameter of 50 μm by spinning disk spinning method to provide sucrose particles with a particle size of 250 μm;

[0050] Dissolve polylactide-glycolide (PLGA) in acetone at a mass volume ratio of 5% g / ml, and stir magnetically to obtain a polylactide-glycolide solution;

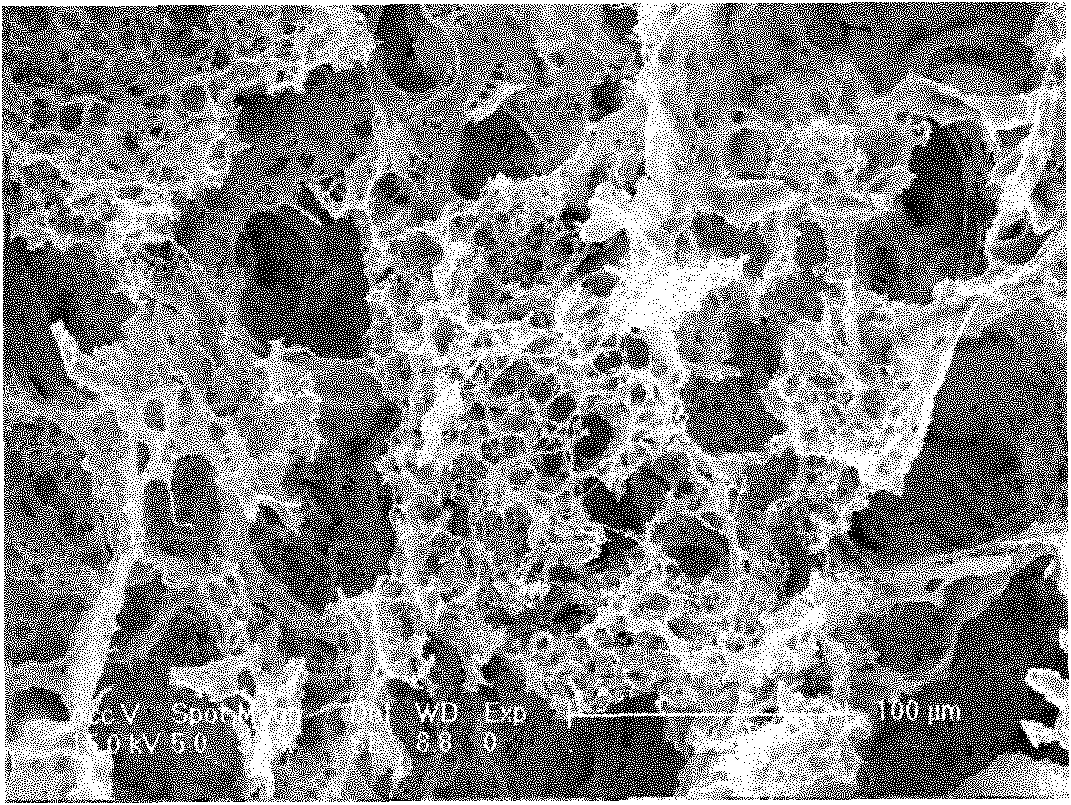

[0051] The sucrose fiber is shredded, mixed with the sucrose particles at a weight ratio of 1:1, and then mixed with the polylactide-glycolide solution, and the weight ratio of the PLGA to the sucrose fiber and particles is 1:4:4, stir evenly, freeze at -20°C, then use a vacuum pump to sublimate acetone in a 4°C freezer to obtain a complex, put the obtained complex into distilled water, and constantly replace the distilled water to make sucrose fiber and sucrose The particles are dissolved and dried to obtain tissue engineering scaffold materials. The scanning electron microscope picture of the tissue engineering scaffold material prepared in this embodiment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com