Resin composition

A resin composition, resin technology, applied in the field of resin composition, can solve the problems of limited use, low glass transition temperature, etc., and achieve the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

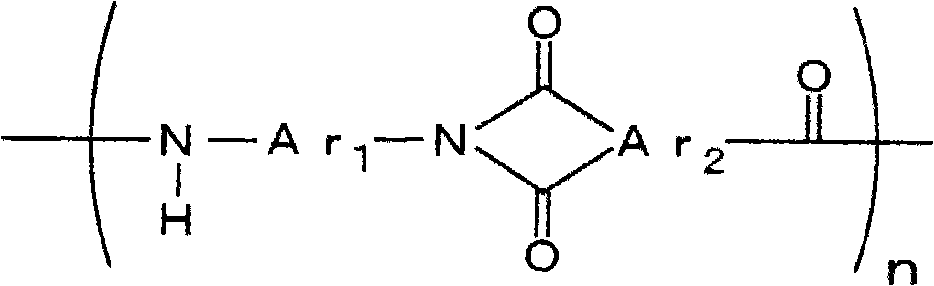

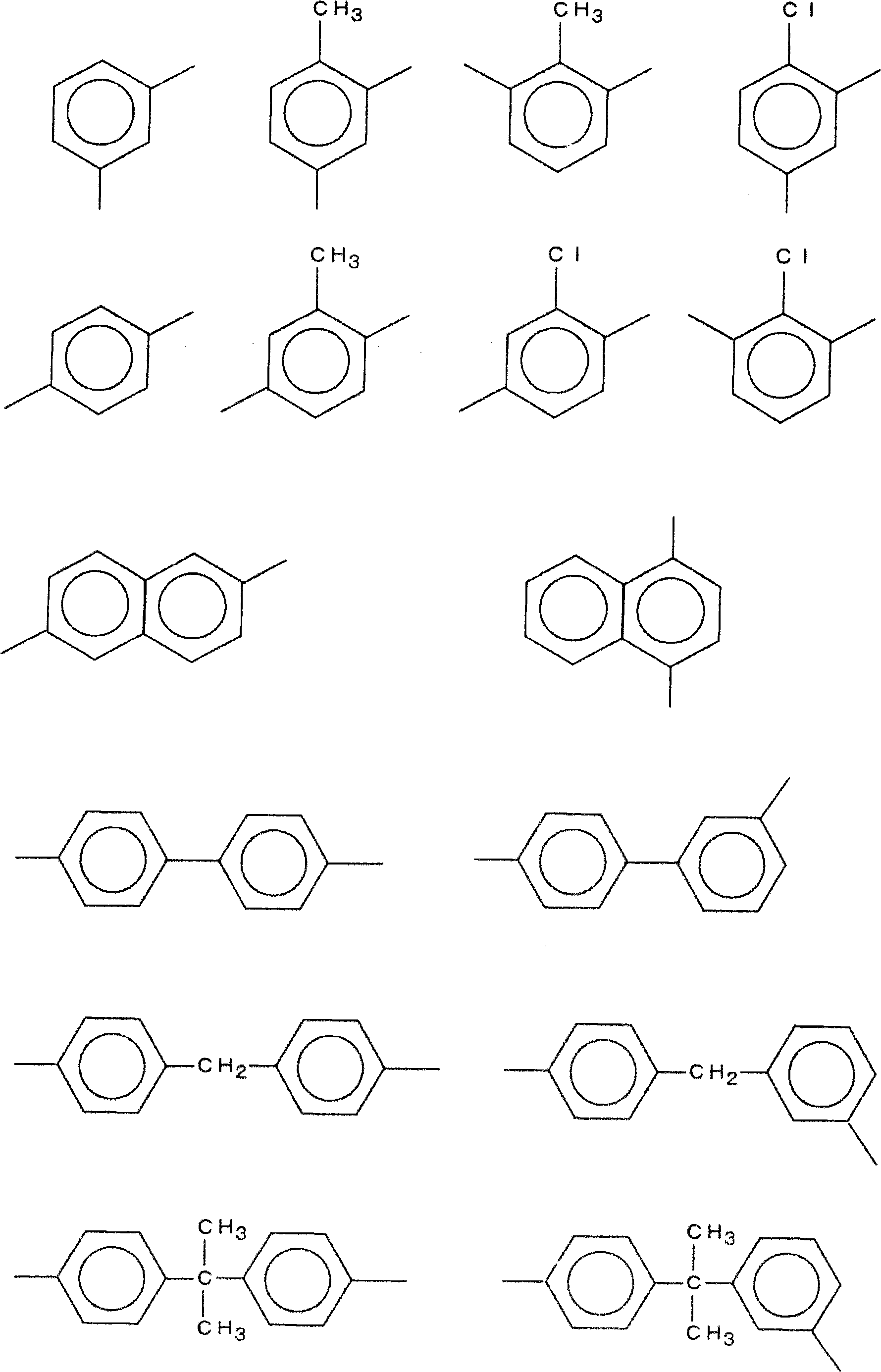

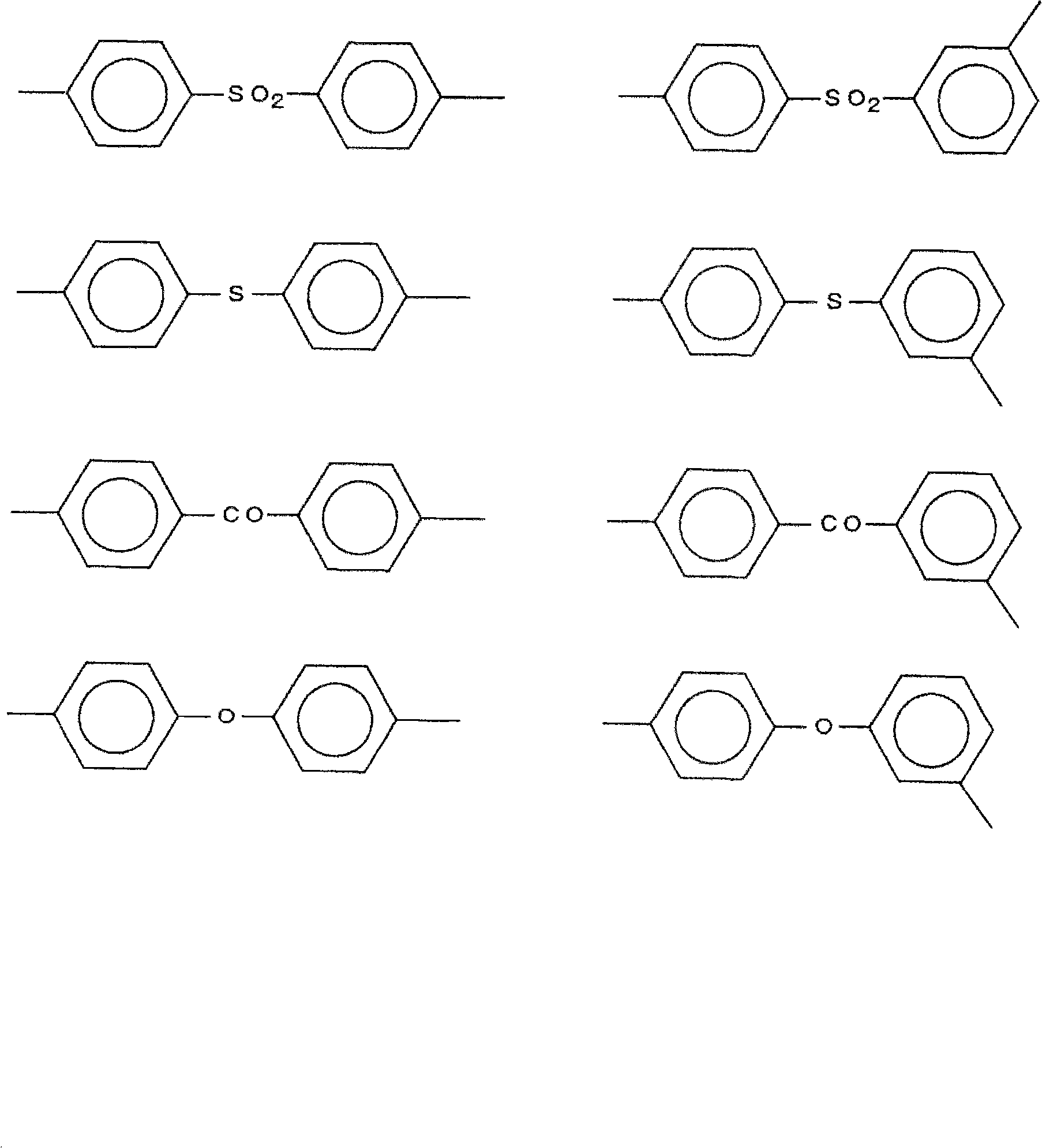

Method used

Image

Examples

Embodiment

[0065] The present invention will be described in more detail by way of examples, but the present invention is not limited to these examples. In addition, the PAI resins used in the following examples and comparative examples were produced in the following synthesis examples.

Synthetic example 1

[0067] 3000 g of N-methylpyrrolidone with a moisture content of 15 ppm was charged into a 5 liter reactor having a stirrer, a thermometer, and a reflux condenser topped with a drying tube filled with calcium chloride. Thereto, 555 g of anhydrous trimellitic acid (50 mol %) were added, followed by 503 g of 2,4-toluene diisocyanate (50 mol %), and 2.955 g of pure water were added. Next, the moisture content in the system was measured using a Karl Fischer moisture meter, and it was found that the moisture content in the system after adding pure water was 1000 ppm. Initially, it took 30 minutes to raise the temperature of the content from room temperature to 120° C., and the temperature was maintained to continue the polymerization reaction for 8 hours. After the completion of the polymerization reaction, the polymerization solution was added dropwise to methanol having twice the volume of N-methylpyrrolidone under vigorous stirring to precipitate the polymer. The precipitated po...

Synthetic example 2

[0069] A PAI resin was obtained in the same manner as in Synthesis Example 1, except that 0.555 g of pure water was added so that the water content in the system after the addition of pure water was 200 ppm. The reduced viscosity of this PAI resin was measured in the same manner as in Synthesis Example 1, and the reduced viscosity was 0.32 dl / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com