Electromagnetic valve type urea solution injector

A technology of solenoid valves and injectors, which is applied in the direction of machines/engines, chemical instruments and methods, mechanical equipment, etc., can solve the problems of urea crystallization blocking nozzle holes, etc., and achieve the goals of reducing working temperature, increasing contact area, and improving reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

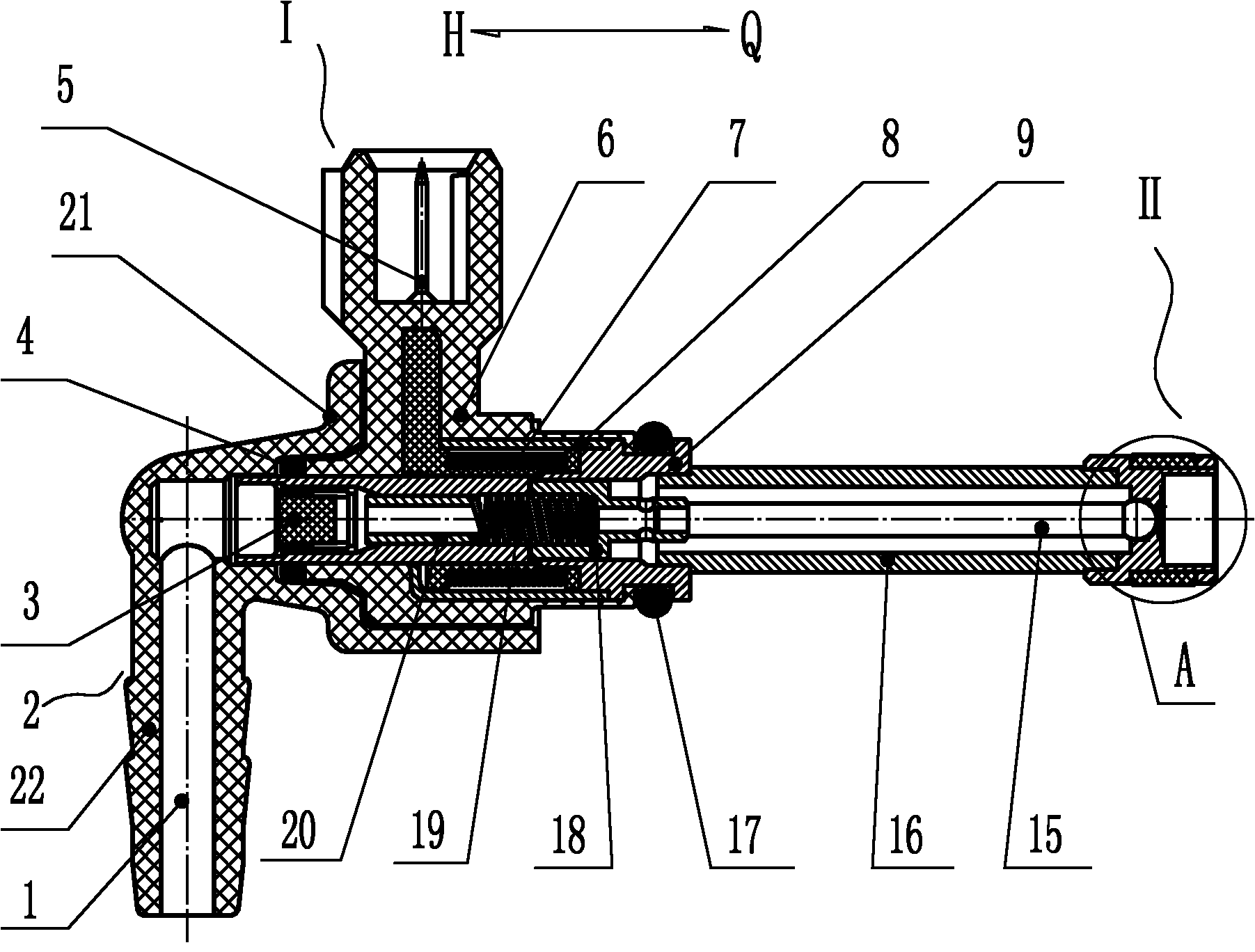

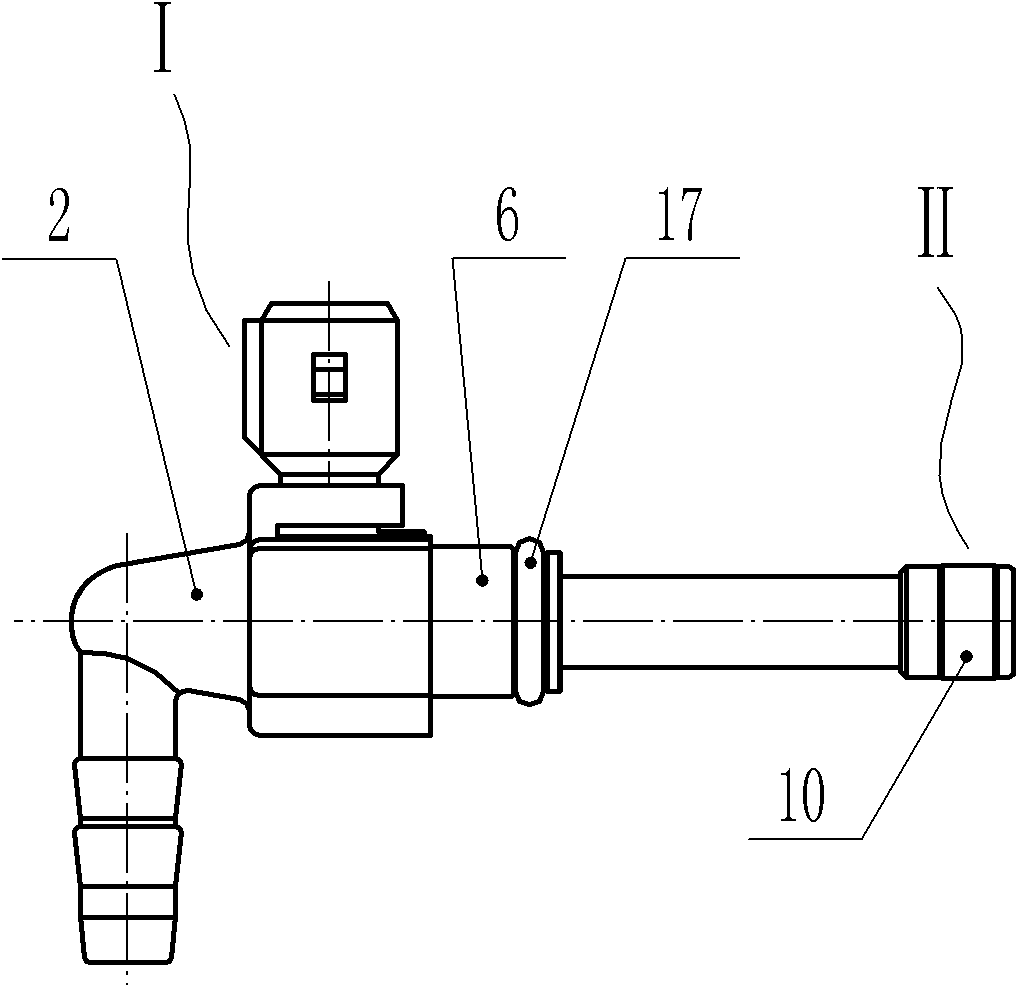

[0036] like figure 1 As shown, a solenoid valve injector for urea solution includes a solenoid valve injector I with a solution input port, a nozzle II with a spray hole, and the nozzle II is connected to the solenoid valve injector through a nozzle connecting rod 16. The spray body I is connected into one body to lengthen the length of the nozzle, increase the contact area between the nozzle and the cooling water, and enhance the cooling effect of the injector.

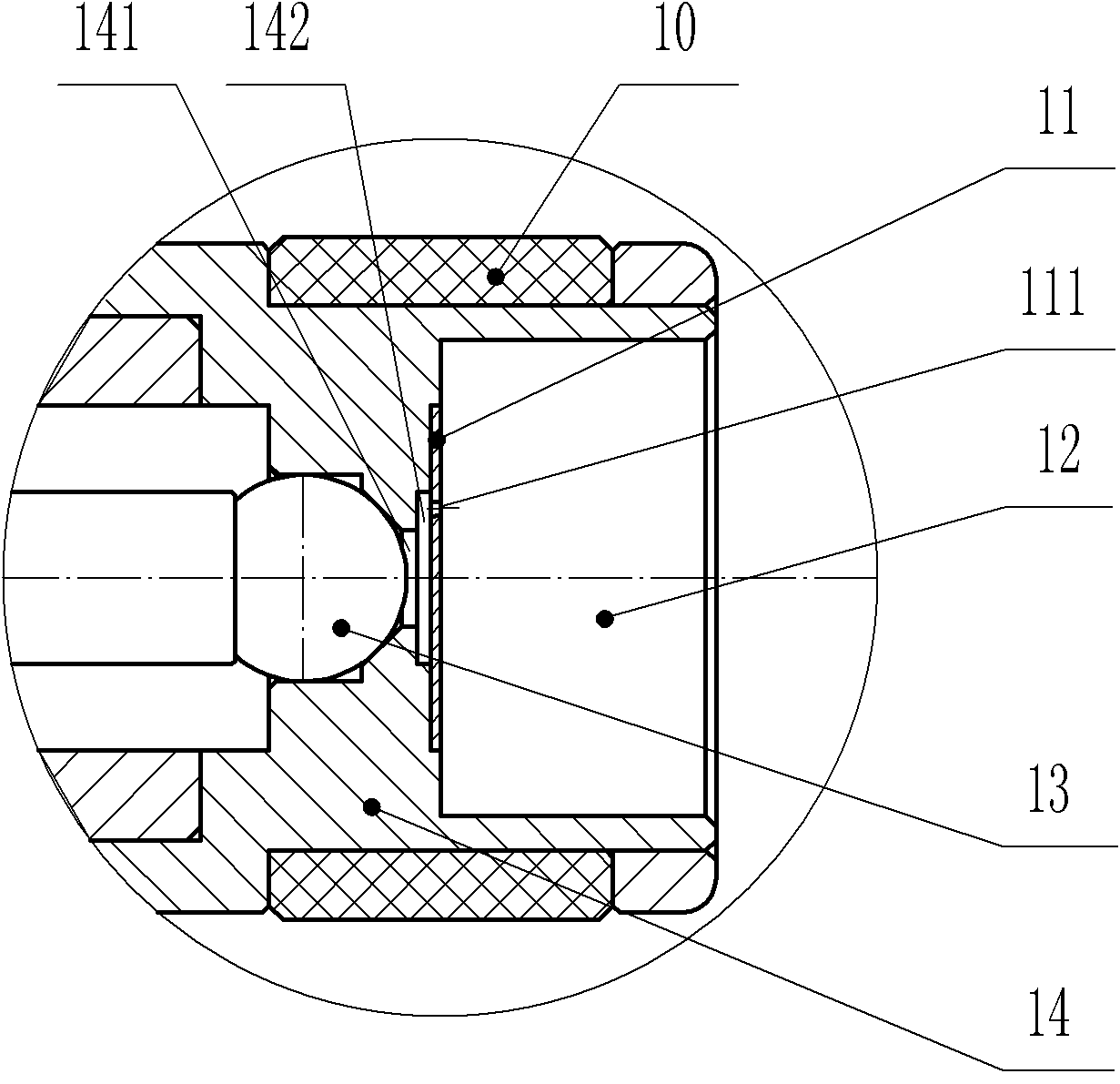

[0037] The nozzle II includes a valve seat 14 provided with a valve 141, a sealing steel ball 13 installed at the valve 141, an orifice plate 11 installed at the front end of the valve and having the spray hole 111 (see figure 2 ), and the valve seat 14 is provided with a step hole 12 forming a turbulent flow chamber A between the front end Q end and the nozzle plate 11; The thermal energy of the tail gas discharge pipe is introduced into the thermal insulation cover 10 of the nozzle; there is only one spray hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com