Multi-substrate large-size hydride vapor phase epitaxy method and device

A hydride gas phase, large-scale technology, applied in chemical instruments and methods, from chemically reactive gases, electrical components, etc., can solve the problems of limiting the yield of GaN substrates, limited range of uniform growth, and limited epitaxial film quality, etc. Achieve the effect of prolonging the growth time of a single furnace, uniform distribution of the deposition rate, and improving the output of a single furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

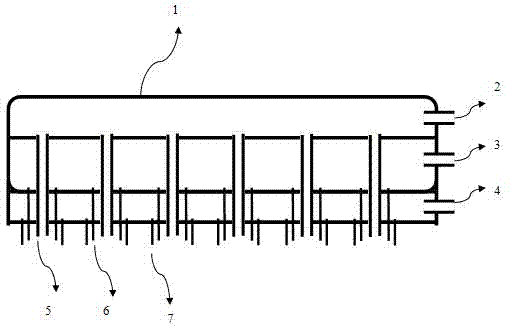

[0037] Horizontal HVPE growth system, buffer layer growth temperature 700°C, growth time 30s~300s, HCl and NH 3 It is passed into the reaction chamber at a ratio of 1:30, the carrier gas is nitrogen or hydrogen, and the typical flow rate is 15SLM. Raise the temperature to a growth temperature of 930°C to 1030°C, grow a GaN thick film for 10 hours, with a thickness of more than 700 microns, growth conditions: HCl and NH 3 The ratio is 1:30, but the flow rate is increased. The HCl flow rate is 500sccm~1500sccm. The carrier gas flow rate is adjusted according to the flow field to ensure uniform GaCl and NH on the tray under the nozzle 3 distributed.

[0038] After the growth is completed, the tray is pulled out from the growth area, and the cooling rate is adjusted by controlling the speed of pulling out. When the temperature is higher than 700°C, the cooling rate is controlled at 5°C / min, and when the temperature is lower than 700°C, the cooling rate is increased to 40°C / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com