Crude oil viscosity-reducing and depressant composite

A composition and crude oil technology, applied in drilling compositions, silicon compounds, inorganic chemistry and other directions, can solve the problem that the temperature rise of waxy crude oil has a great influence on low temperature rheology, it is difficult to fully meet the safe operation conditions of pipelines, and the waxy crude oil The problem of static stability, short aging, etc., achieves excellent aging, good pour point and viscosity reduction and drag reduction, and the effect of improving low temperature fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

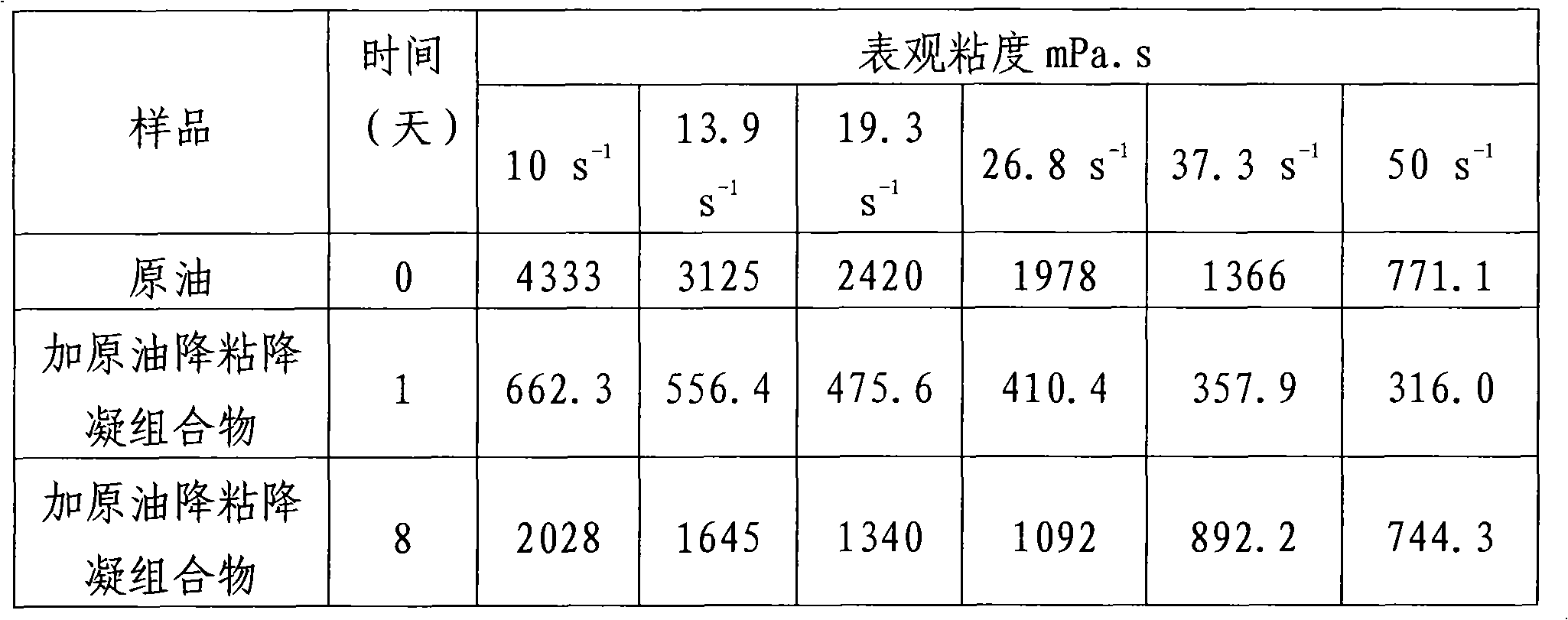

[0032] Embodiment 1. Commercially available bentonite, particle size 325 mesh, particle diameter ≤ 45 μm. Its active ingredient is sodium-based montmorillonite with a content of 90%. The viscosity and pour point depressing composition composed of sodium montmorillonite and ethylene-vinyl acetate copolymer pour point depressant is added to waxy crude oil in the following manner: first, 50 ppm by weight of sodium montmorillonite and 50 ppm by weight of ethylene- The crude oil viscosity and pour point depressant composition of vinyl acetate copolymer pour point depressant is dispersed in diesel oil at a concentration of 1 wt%, and then added to waxy crude oil, and the temperature is controlled at about 64°C; mechanically stirred at a speed of 10,000 rpm to reduce the viscosity of crude oil The pour point depressing composition is uniformly dispersed in the crude oil, stirred for 5 minutes and then cooled. Store at 25°C. The viscosities of the crude oil added with the crude oil ...

Embodiment 2

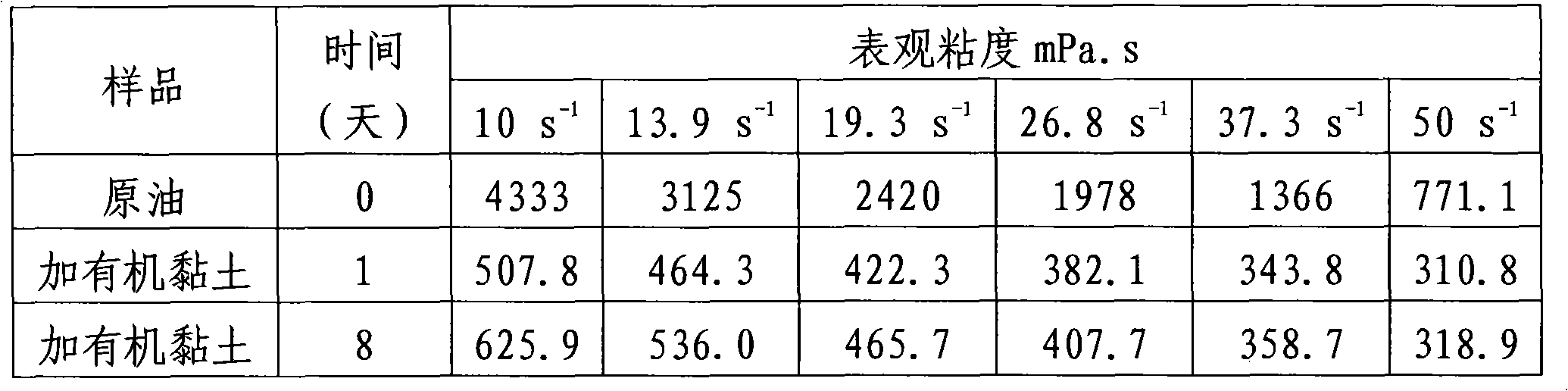

[0034] Embodiment 2. Preparation of organic montmorillonite: stirring 100 g of raw material sodium montmorillonite in 500 ml of deionized water dispersion medium to form suspension dispersion A; then treating agent dioctadecyl dimethyl ammonium chloride 70g was added to the suspension A, and the mixture was stirred and reacted at 80-90°C for 4.5 hours and then filtered; the filtrate was washed several times with deionized water until no halide ions existed in the washing liquid. The filtrate is dried and pulverized to obtain an organic clay with a particle size of 20-30 μm and a modified component of dioctadecyldimethylammonium cation.

[0035] The organoclay modified by dioctadecyldimethylammonium cation is added in the waxy crude oil in the following way: first, the organoclay modified by 50 ppm by weight of dioctadecyldimethylammonium cation is directly added to the organoclay containing In the waxy crude oil, control the temperature at about 55°C; mechanically stir at a sp...

Embodiment 3

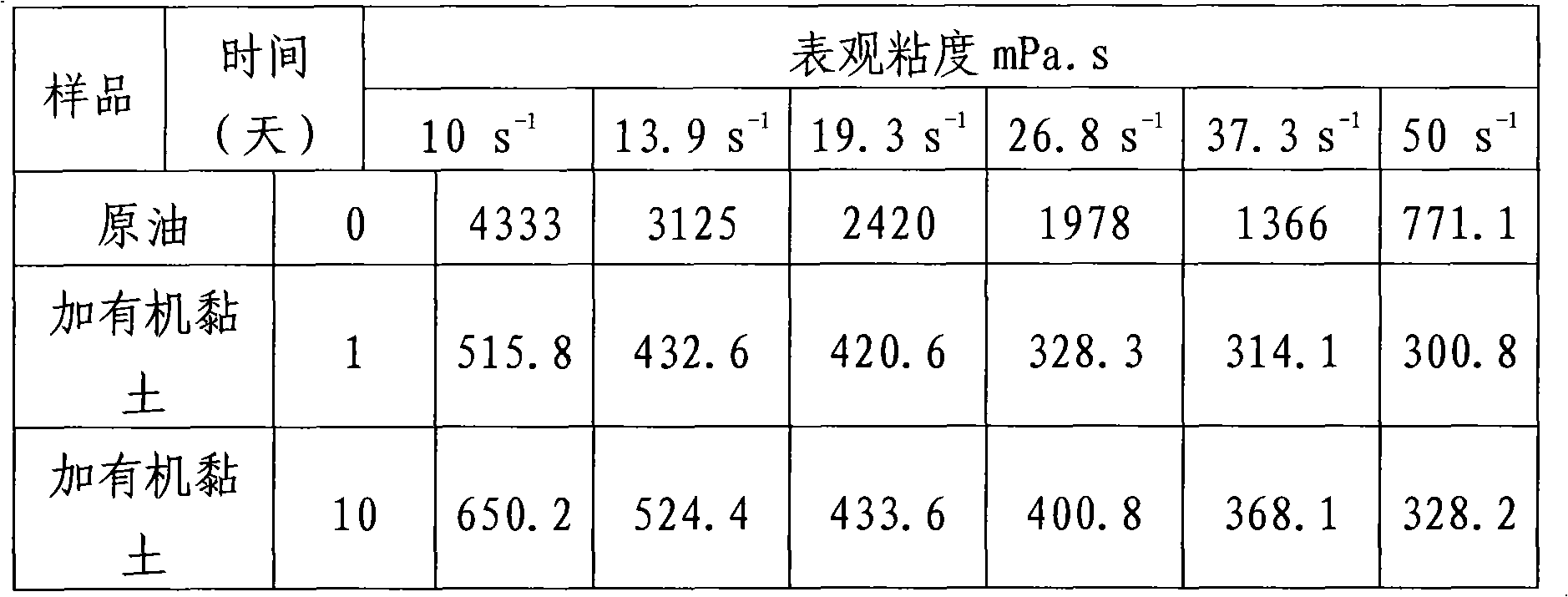

[0037] Example 3. Preparation of organic montmorillonite: 100 g of raw material sodium montmorillonite was stirred in 500 ml of deionized water dispersion medium to form suspension dispersion A; then 60 g of treatment agent dihydrogenated tallow dimethyl ammonium was added In suspension A, the mixture was stirred and reacted at 80-90°C for 4.5 hours and then filtered; the filtrate was washed several times with deionized water until no halogen ions existed in the washing liquid. The filtrate is dried and pulverized to obtain an organic clay with a particle size of 20-30 μm and a modified component of double hydrogenated tallow dimethyl ammonium cation.

[0038] The organic clay modified by double hydrogenated tallow dimethyl ammonium cation is added in the waxy crude oil in the following way: first the organic clay modified by double hydrogenated tallow dimethyl ammonium cation with 10wt% Disperse the concentration of the organic clay in xylene, then add it to the waxy crude oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com