Treatment method of potato type non-grain starch fuel ethanol distiller solution

A technology of fuel ethanol and a treatment method, which is applied in the fields of sewage treatment and comprehensive utilization of resources, can solve the problems of high treatment cost, difficult to develop large-scale industrialization, and is not suitable for large-scale treatment systems, and achieves the effect of high-efficiency phosphorus and nitrogen removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

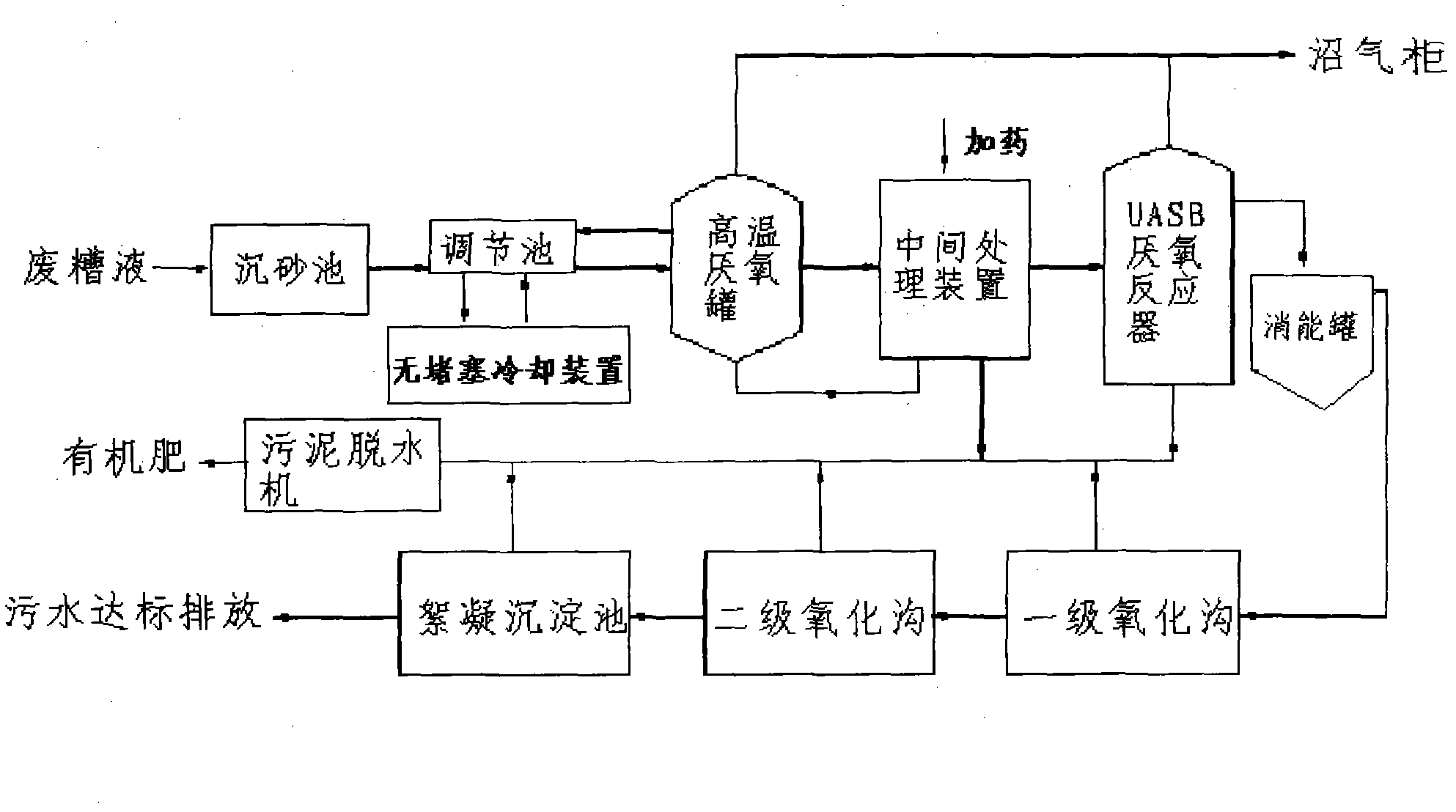

[0019] The method for processing potato non-grain starchy fuel ethanol residue as shown in Figure 1 is characterized in that it is realized by the following process steps:

[0020] 1. Pre-treatment of waste liquid: the waste liquid passes through the grit chamber to remove heavy impurities, and then filters the residue through a mesh plate with a pore size of 0.5-1.5 mm, and then enters the regulating tank to adjust the water quality, water quantity, and water temperature through a non-clogging cooling device to control Uniform water quality: COD Cr =40000~80000mg / l, water volume: buffer time 2~3h, water temperature: 55~60℃;

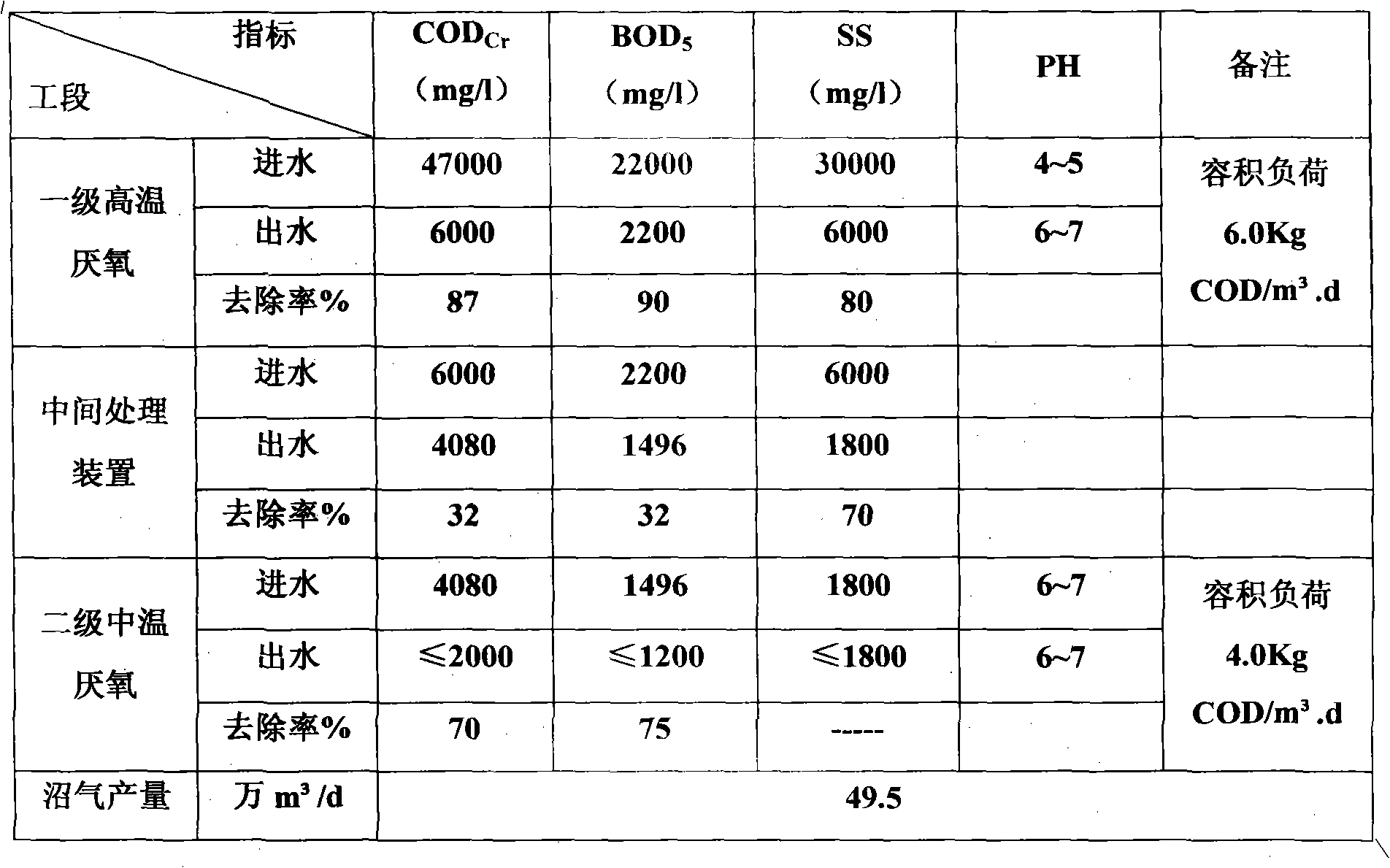

[0021] 2. Primary anaerobic treatment: the effluent from the regulating tank enters the high-temperature anaerobic tank for fermentation, the influent COD concentration is 40,000-80,000mg / l, the temperature is controlled at 55-60°C, the removal rate is above 85%, and the generated biogas is collected and utilized;

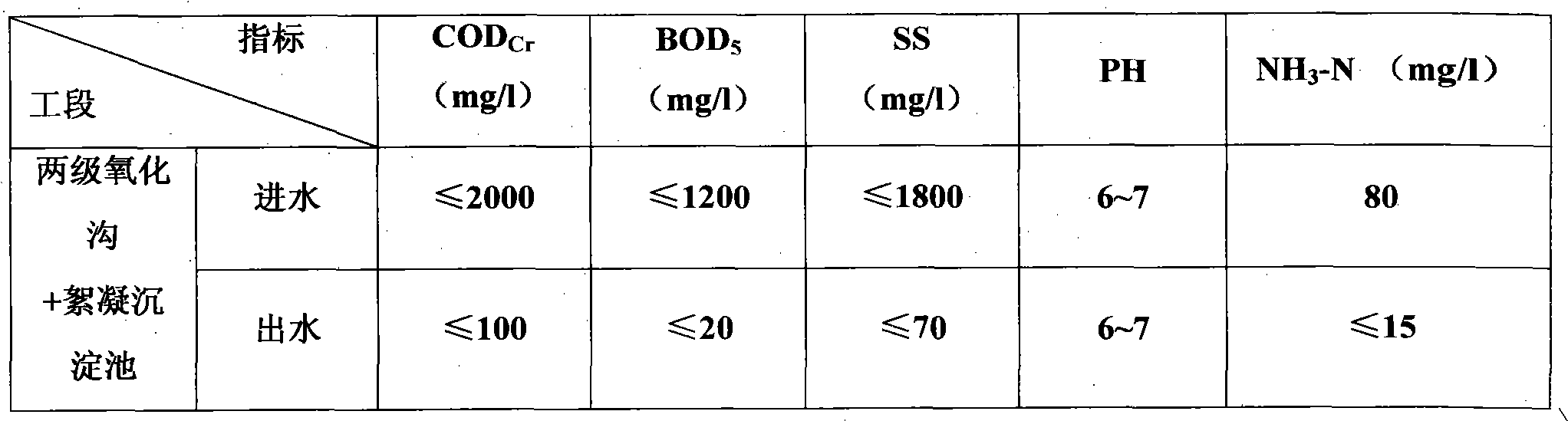

[0022] 3. Intermediate treatment: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com