A Research Method for the Influence of Substrate Support Stiffness Gradient Variation on Friction Force

A technology of gradient change and friction force, applied in the field of molecular dynamics, to achieve the effect of simple operation, improved efficiency and stable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below in conjunction with specific drawings and examples.

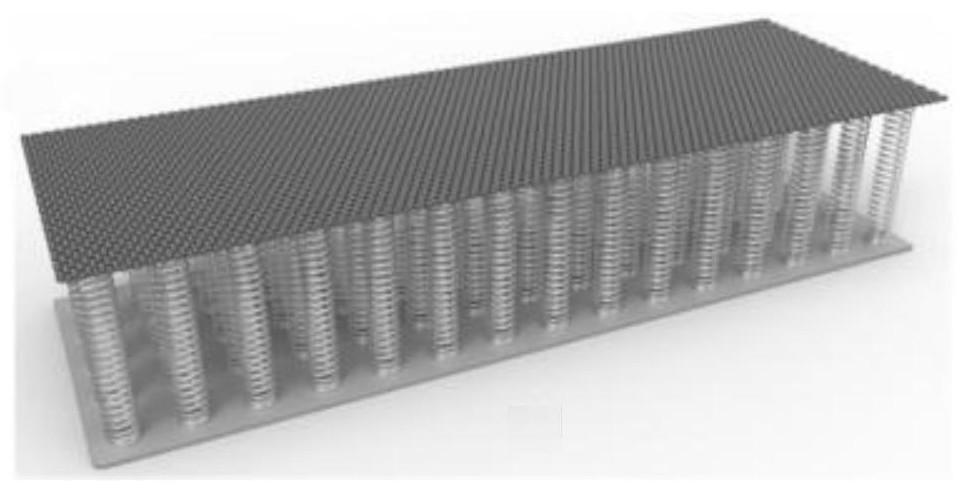

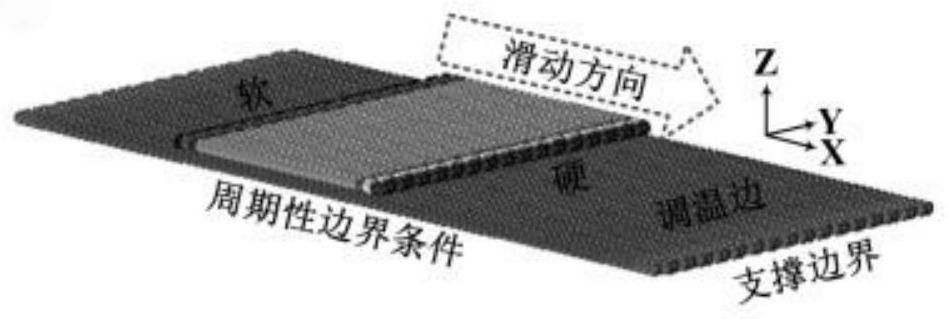

[0031] 1, molecular dynamics model

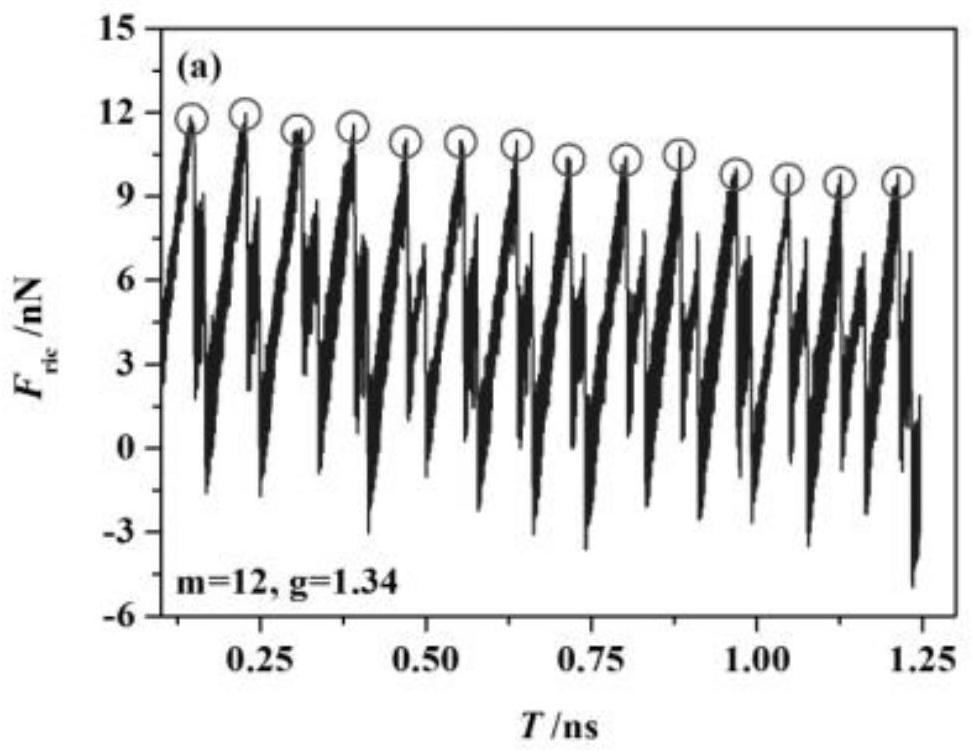

[0032] The model system established by this method includes an analog atomic force microoscope (ATOMIC Force Microscope, a single layer graphene element supported by a single graphene sheet and stiffness gradient supported by AFM) probe pip adsorption, such as figure 1 Indicated. The support and substrate graphene are connected to each atom of the substrate graphene in the X direction. In order to simulate the probe creating arm, the graphene sheet centroid spring is attached to the outer virtual atom (corresponding to the cantilever beam) sliding in constant speed 3 m / s, the sheet and the substrate in the sliding direction are serrated in the sliding direction of the sliding direction. The degree of contact is contacted and is equivalent to the Y direction, and is stacked in an AB mode. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com