A method for study that effect of the gradient change of the rigidity of base brace on the friction force

A technology of gradient change and friction force, applied in the field of molecular dynamics, to achieve the effect of simple operation, strong controllability and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

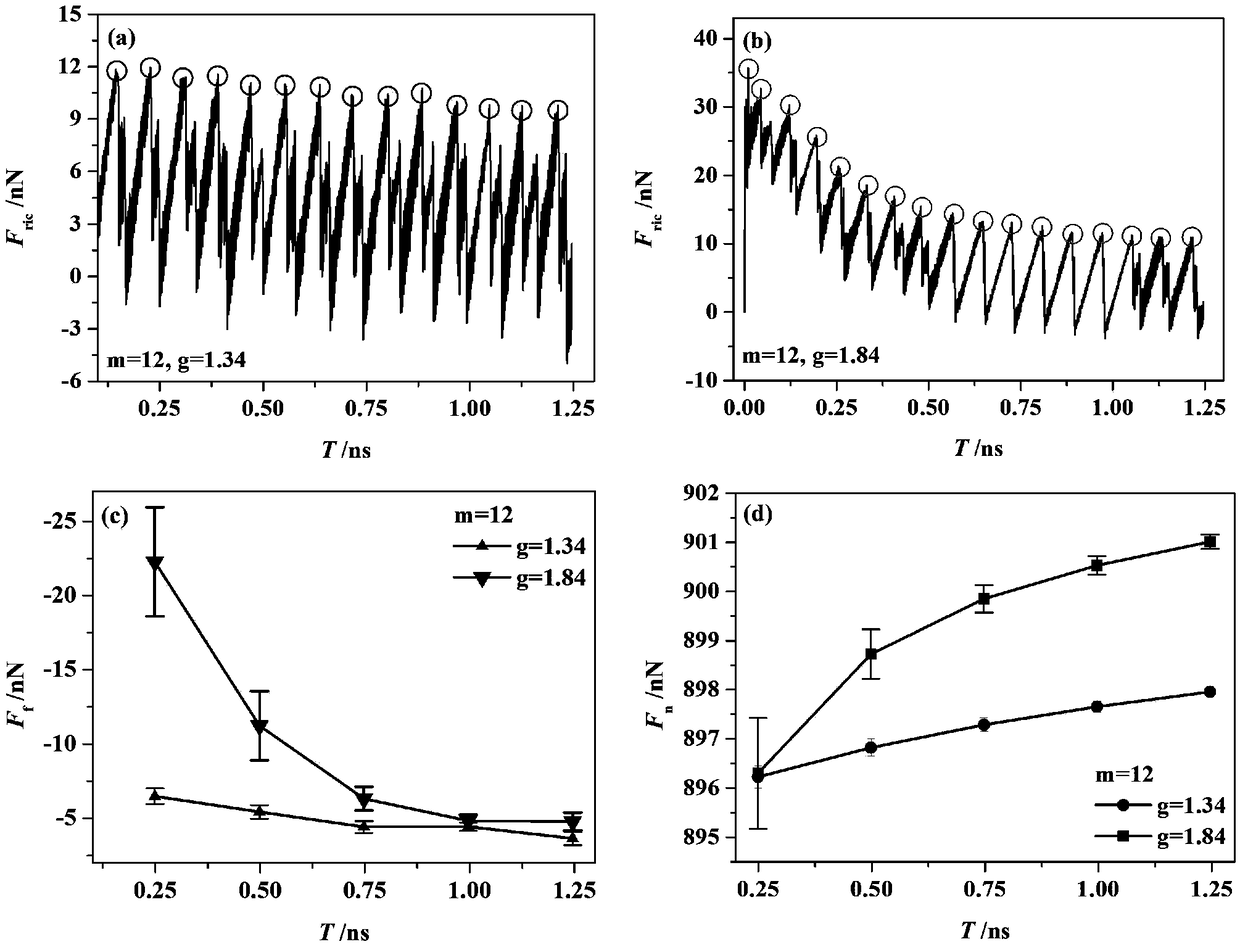

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in further detail below in conjunction with specific drawings and examples.

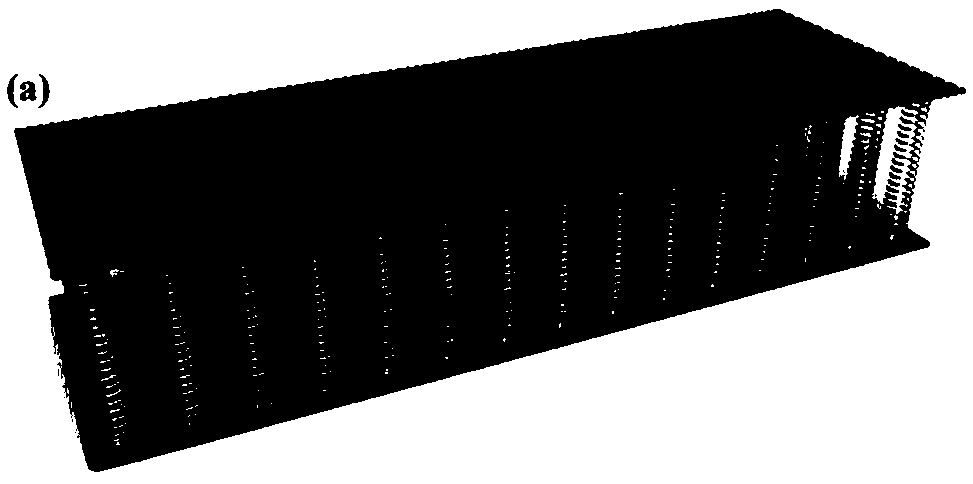

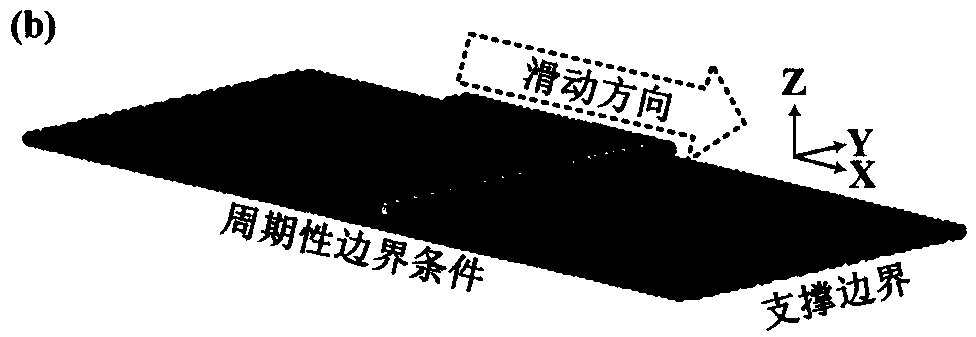

[0031] 1. Molecular dynamics model

[0032] The model system established by this method includes a square graphene sheet adsorbed by the tip of an atomic force microscope (abbreviated as AFM) and a single-layer graphene substrate supported by a stiffness gradient, as shown in FIG. 1 . The support body and each atom of the substrate graphene are connected by a spring bed whose normal stiffness increases linearly along the X direction. In order to simulate the probe cantilever, the centroid of the graphene sheet is connected with a spring to an external virtual atom (equivalent to a cantilever beam) that slides at a constant speed of 3 m / s along the X direction. The sheet and the substrate are both zigzag in the sliding direction (that is, degrees of contact) and the same width in the Y direction, and stacked in the A-B manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com