Method for disassembling and modifying printed circuit board based on high temperature steam

A technology of high-temperature steam and waste circuit boards, which is applied in the removal of solid waste, recycling of electronic waste, and manufacturing tools, etc., can solve the problems of complex structure, difficult operation, and difficulty in adapting to the disassembly of circuit boards of different types and sizes. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

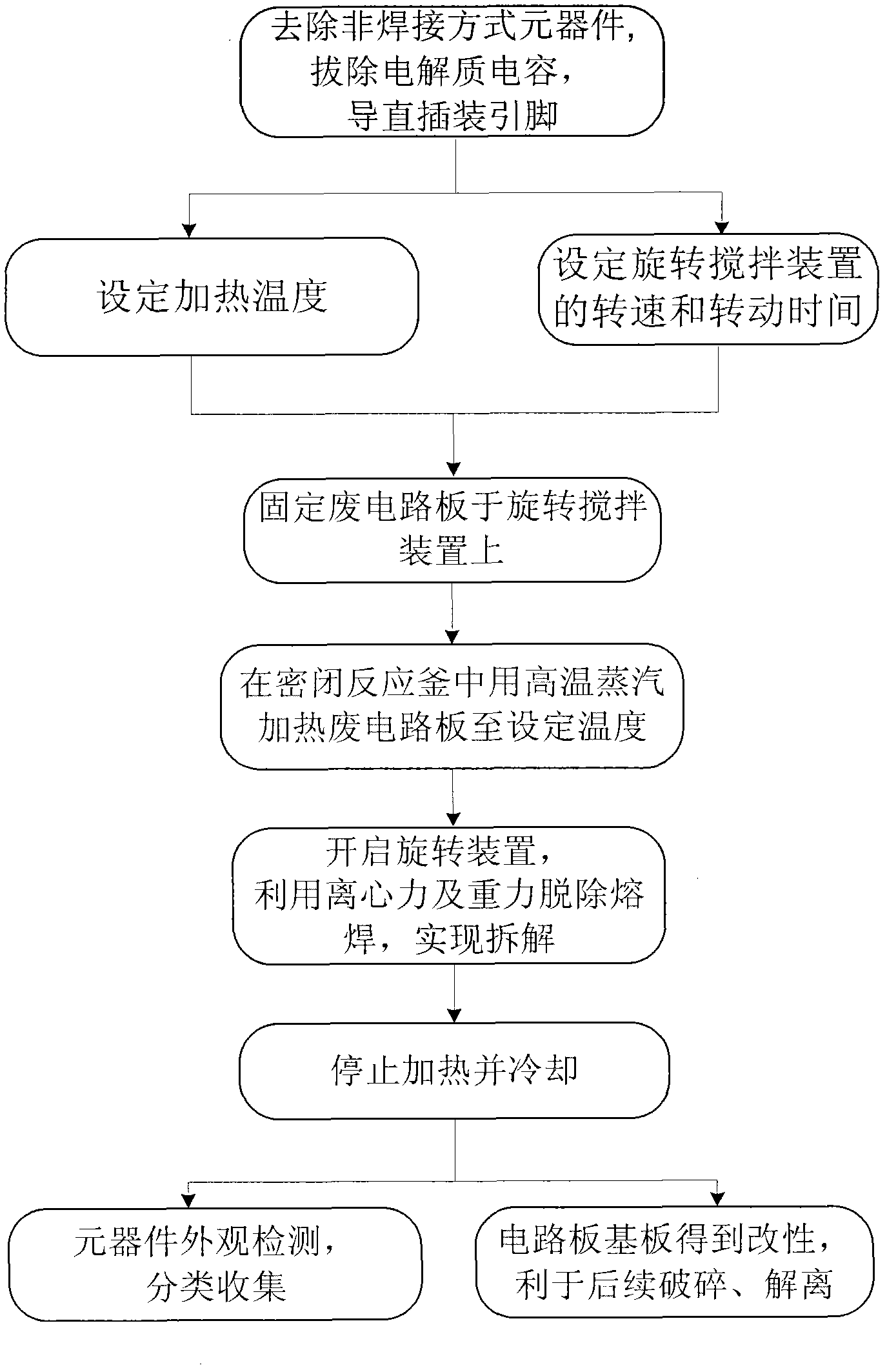

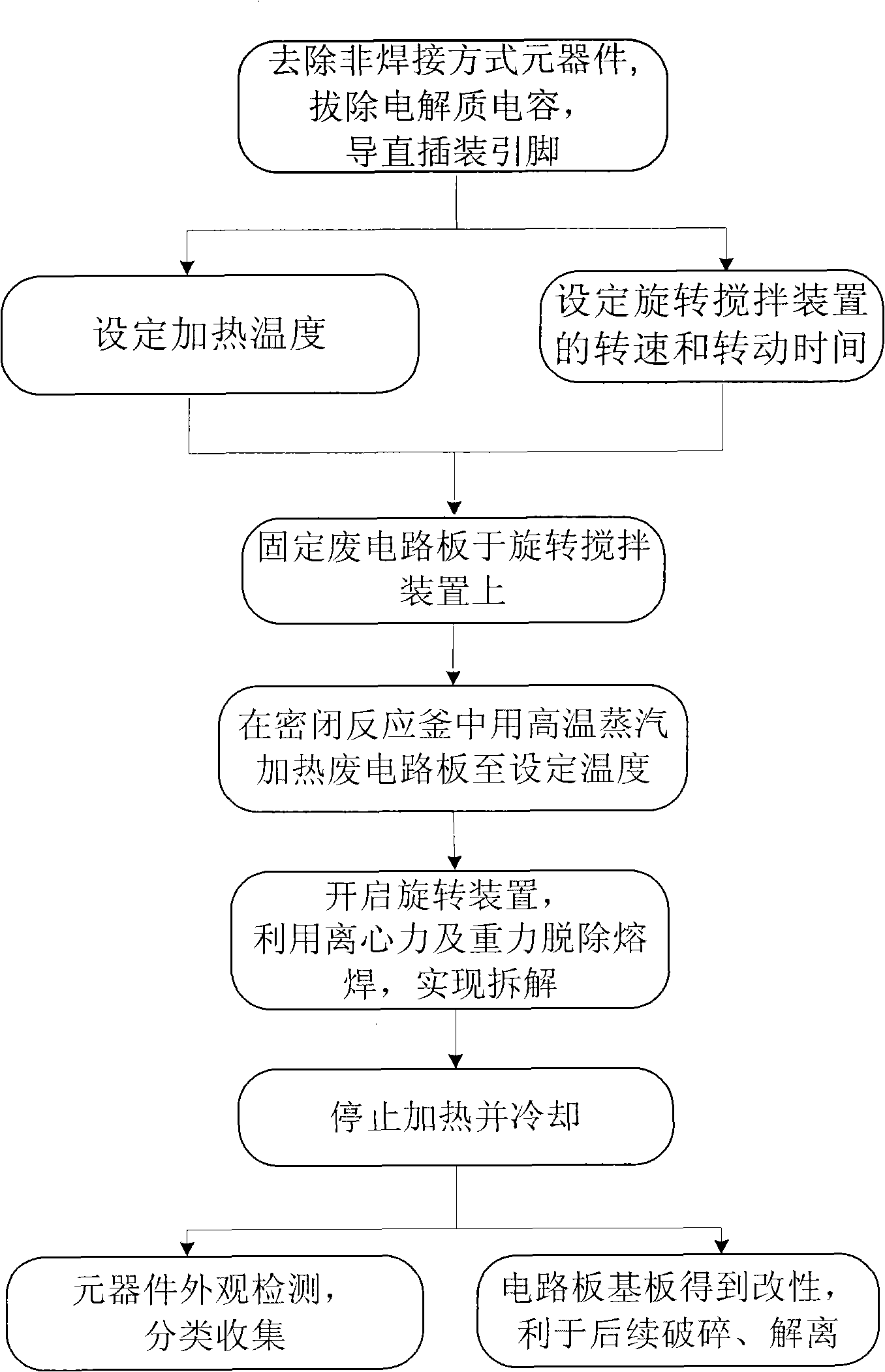

Method used

Image

Examples

Embodiment 1

[0030] Computer memory chip disassembly

[0031] The first step is to take a piece of used computer memory. There are no non-solder connection components and electrolytic capacitors on it. All chips are packaged in dual surface mount (SOP). It is judged that the solder used is the 63Pb37Sn solder that is most commonly used in current computer originals, and its melting point is 183°C. Therefore, the final heating temperature is set to 190°C, the rotation speed is set to 300 rpm, and the rotation time is set to 30s.

[0032] The second step is to fix the waste memory on the rotating stirring device in the reactor, and adjust the length of the stirring device to 6.5 cm so that the waste circuit board is 1 cm away from the inner wall of the reactor.

[0033] In the third step, a closed high-temperature steam generator is used to generate high-temperature steam into the reactor, and the waste memory in the reactor is heated to 190°C. Turn on the rotating device to rotate at the set spe...

Embodiment 2

[0037] Dismantling of circuit boards based on plug-in resistors

[0038] The first step is to take a piece of the circuit board, the resistors on it are all in-line plug-in packages, and the leads are straight. It is judged that the solder used is 63Pb37Sn solder which is most commonly used currently. Set the final heating temperature to 200°C, and set the rotation speed to 700 rpm and the rotation time to 3 minutes.

[0039] In the second step, the circuit board is fixed on the rotating stirring device in the reactor, and the length of the stirring device is adjusted to 6.5 cm, so that the waste circuit board is 1 cm away from the inner wall of the reactor.

[0040] In the third step, a closed high-temperature steam generator is used to generate high-temperature steam into the reactor, and the circuit board in the reactor is heated to 200°C. Turn on the rotating device to rotate at the set speed for 3 minutes, use the combined effect of centrifugal force and gravity to remove the ...

Embodiment 3

[0044] Disassembly of circuit boards mainly based on BGA packaged chips

[0045] Ball grid array (BGA) packaging is one of the typical surface-mounting forms, and the south and north bridge chips of computer motherboards all adopt this packaging form.

[0046] The first step is to take a piece of this kind of circuit board, and the chip on it is a BGA package. It is judged that the solder used is 63Pb37Sn solder which is most commonly used currently. Set the final heating temperature to 200°C, and set the rotation speed to 650rpm and the rotation time to 25s.

[0047] In the second step, the circuit board is fixed on the rotating stirring device in the reactor, and the length of the stirring device is adjusted to 6.5 cm, so that the waste circuit board is 1 cm away from the inner wall of the reactor.

[0048] In the third step, a closed high-temperature steam generator is used to generate high-temperature steam into the reactor, and the circuit board in the reactor is heated to 200°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com