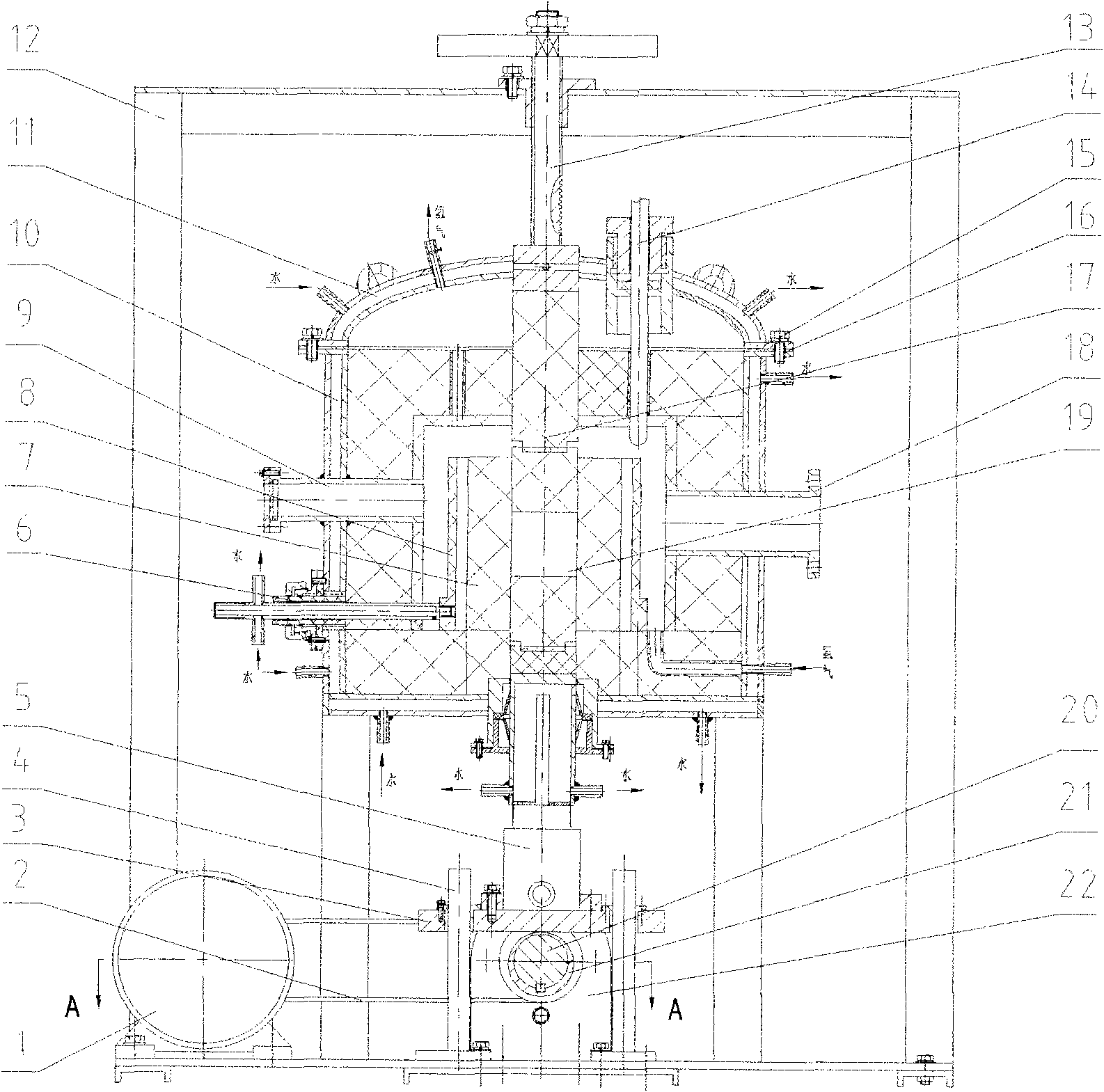

Pressure-adjustable vibratory type hot pressed sintering furnace

A hot-pressed sintering furnace and adjustable pressure technology, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of increasing sintering costs, multiple energy sources, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

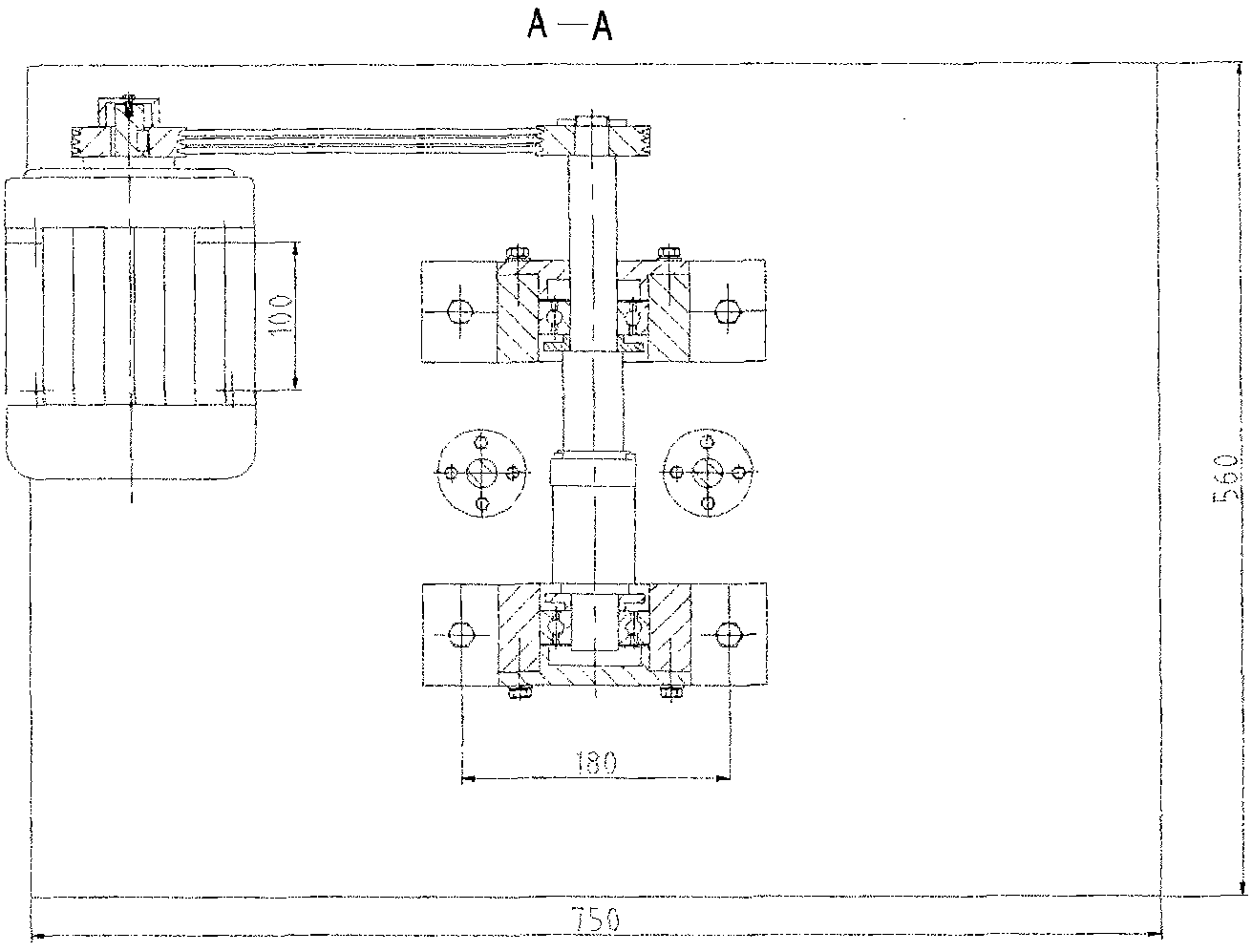

[0013] The present invention will be further introduced below in conjunction with the drawings of the description, but not to limit the present invention. First, manually loosen the handwheel screw compression mechanism 13 to a suitable position, open the furnace cover 11, put the mold 7 with raw materials into the furnace chamber 10, close the furnace cover 11, and tighten the handwheel screw compression mechanism 13 to Compress the furnace cover 11 at a suitable position, and then tighten the bolts on the connecting ears, so that the furnace chamber 10 is in a sealed state. The furnace chamber 10 is vacuumized and / or passed into an inert gas (or other protective gas) by the vacuum flange 18, and the pressurizing device 5 is started to pressurize the material in the mold 7 in the furnace chamber 10 (also can Simultaneously energize and heat), after the material pressure and temperature reach a certain value, start the efficient flow variable frequency motor 1, the speed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com