Construction method for connecting concrete thin-wall pipe pile by wooden supporting plate

A thin-walled pipe pile and construction method technology, applied in sheet pile wall, infrastructure engineering, construction, etc., can solve the problems of solid waste environment pollution, human health impact, high labor intensity, etc., to save labor, eliminate solid The effect of waste pollution and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

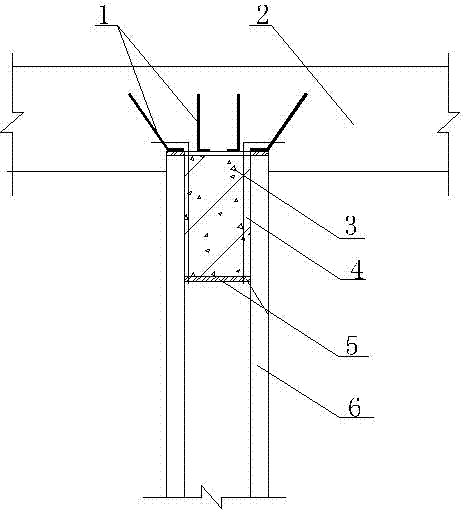

[0039] Example 1 as figure 1 As shown, when the end top elevation of pipe pile 6 is the design elevation, connect the pile with the following operation steps:

[0040] First make the skeleton steel bar 1, and weld the steel bar on the end of the pipe pile 6, and the end of the pipe pile 6 is equipped with a steel plate for welding; make the supporting plate 5, and use nine splints to make a diameter smaller than the pile pipe according to the size of the inner diameter of the pipe pile. For a pallet 5 with an inner diameter of 20 mm, saw four or six kerfs with a depth of 20 mm to 30 mm, which are used to embed the iron wire 4. The iron wire 4 used is 12# or 14# iron wire, and the length of the iron wire 4 is for the sinking of the pallet 5 The depth inside the pile tube is 500㎜ + the length of the steel bar binding at the pile end is 200㎜. Insert and adjust the length of the iron wire from the sawing seam so that the lengths of both ends are equal; then put the supporting plat...

Embodiment 2

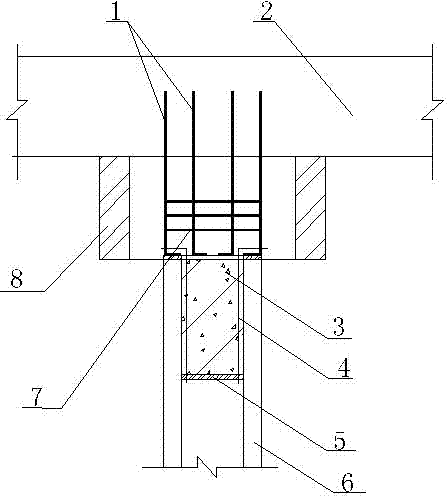

[0041] Example 2 as figure 2 As shown, when the top elevation of the pipe pile 6 is lower than the design elevation, the following steps are used to connect the piles:

[0042]First dig out the soil above the pile end, the excavation hole is a circular hole or a square hole, the inner diameter of the circle or the square hole and the continuous length is the outer diameter of the pipe pile + 200 mm, and then rebuild the masonry protection hole 8, the bottom of which should be lower than the top of the pile 30㎜~50㎜, the top is at the same elevation as the cap or the bottom of the foundation beam, and its thickness is 120-240mm; then make the pile-connected skeleton steel bar 1 and weld it on the top steel plate of the pipe pile 6, the length of the steel bar is the anchorage of the cap length + masonry body protection height + welding length, when the masonry height exceeds 300mm, stirrups 7 can be added to fix it; then support plate 5 is made, and according to the size of the...

Embodiment 3

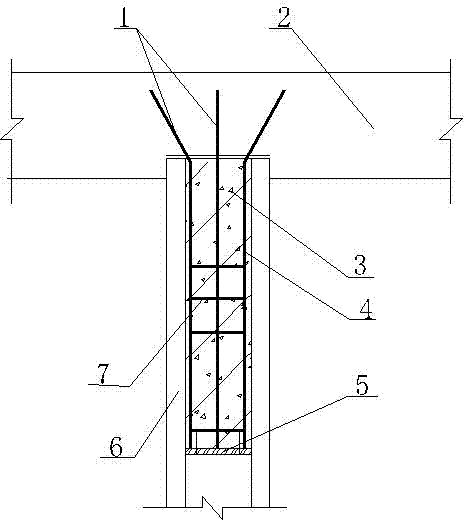

[0043] Example 3 as image 3 As shown, when the end top elevation of pipe pile 6 is greater than the design elevation, use the following steps to connect the pile:

[0044] First according to the design elevation requirement, cut the pile with a pile cutting machine such as a concrete cutter or a saw pile device, and the height of the pipe pile 6 is cut to the design height at one time, and the pile connecting skeleton reinforcement bar 1 and the stirrup bar 7 are made, because the top of the pipe pile 6 is There is no welded steel plate. According to the requirements of 2002 Zhejiang G22 "Detailed Drawing of Pile Top and Cap Connection (1)", the length of the pile connection is 1000 mm + the length of the extension into the cap, and two pieces are welded at 1m away from the lower end of the skeleton steel bar 1. φ20 to horizontally position the steel bar so that the skeleton steel bar does not fall off; then make the supporting plate 5, according to the size of the inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com