Special additive for waste asphalt mixture heat regeneration and preparation method thereof

A waste asphalt, heat regeneration technology, applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of air pollution, difficulty, non-renewable, etc., to save asphalt and gravel materials, simple processing technology, easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

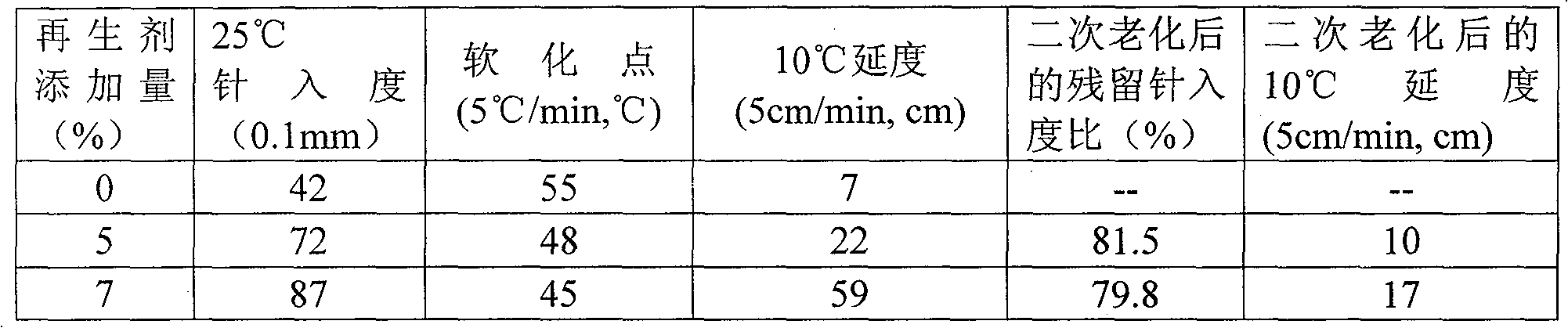

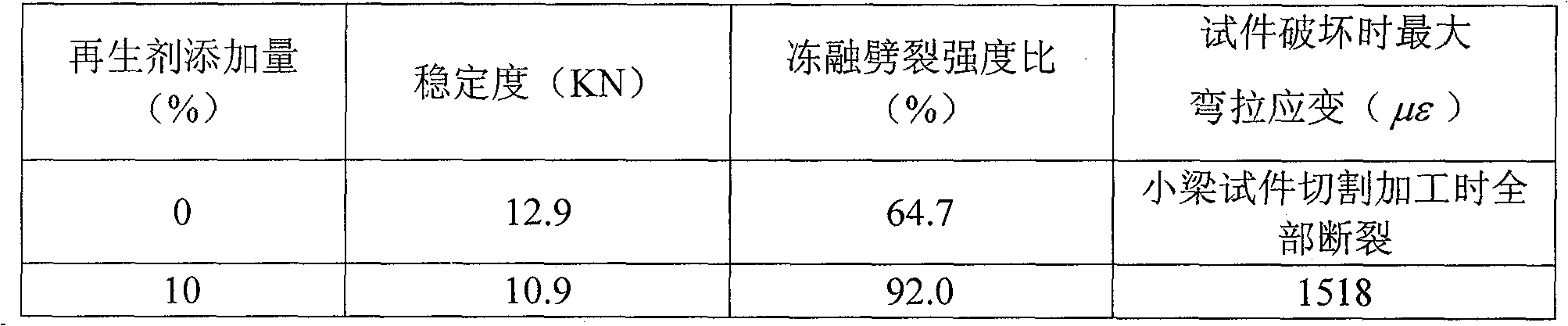

Examples

Embodiment 1

[0021] A special additive for thermal regeneration of waste asphalt mixture, which consists of 50-100 parts of high-aromatic mineral oil, 3-10 parts of tung oil prepolymer, and 5-20 parts of plasticizer according to the ratio of parts by mass. The high-aromatic mineral oil is furfural extracted oil and more than one of coal tar, and the plasticizer is dibutyl phthalate, dioctyl phthalate, and diisooctyl phthalate. more than one.

[0022] The preparation method of described tung oil prepolymer carries out according to the following steps:

[0023] 1), adding aluminum chloride and absolute ethanol solution to tung oil, stirring evenly to form an emulsion;

[0024] 2), the emulsion is heated to 220~250 ℃ and continues to stir for 0~1.5h, is cooled to room temperature, promptly obtains described tung oil prepolymer, and the mass parts of aluminum chloride in its tung oil prepolymer: dehydrated alcohol: tung oil The numbers are 2 to 3 parts: 100 to 200 parts: 500 to 600 parts.

...

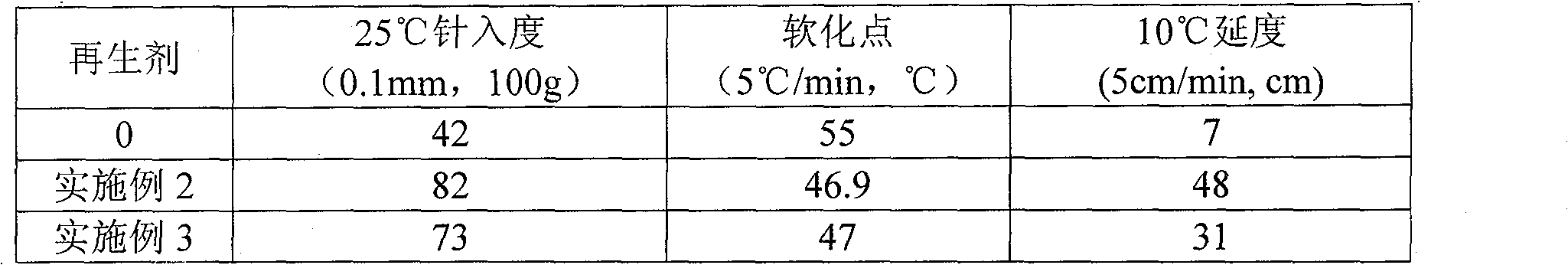

Embodiment 2

[0029] A special additive for thermal regeneration of waste asphalt mixture, which consists of 60-90 parts of high-aromatic mineral oil, 4-8 parts of tung oil prepolymer, and 8-18 parts of plasticizer according to the ratio of parts by mass. The high-aromatic mineral oil is furfural extracted oil and more than one of coal tar, and the plasticizer is dibutyl phthalate, dioctyl phthalate, and diisooctyl phthalate. More than one, the preparation method of tung oil prepolymer and special additive is the same as embodiment 1.

Embodiment 3

[0031] A special additive for thermal regeneration of waste asphalt mixture, which consists of 65-85 parts of high-aromatic mineral oil, 5-7 parts of tung oil prepolymer, and 10-15 parts of plasticizer according to the ratio of parts by mass. The high-aromatic mineral oil is furfural extracted oil and more than one of coal tar, and the plasticizer is dibutyl phthalate, dioctyl phthalate, and diisooctyl phthalate. More than one, the preparation method of tung oil prepolymer and special additive is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com