Application method of high-property activated carbon fibers in treatment of industrial waster water by electrocoagulation

A technology of activated carbon fiber and industrial wastewater, which is applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of high metal electrode loss rate, increased electrode use cost, and reduced electrolysis efficiency. Achieve a wide range of use, improve electrolysis efficiency, and prevent electrode passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The object of industrial wastewater treatment is metal copper nickel chromium electroplating wastewater. The ion concentration and other indicators in the water before treatment are as follows:

[0053] Metal nickel: 60mg / L, metal copper: 80mg / L, metal chromium: 40mg / L, cyanide: 100mg / L;

[0054] COD (chemical oxygen demand); 250mg / L,

[0055] PH=2.3

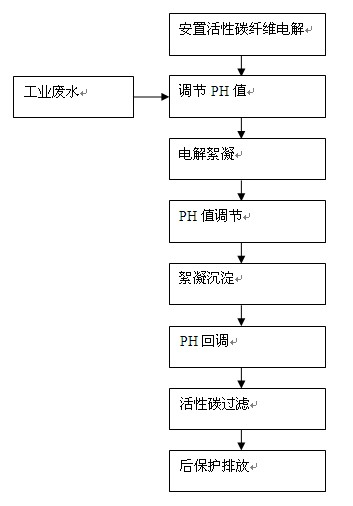

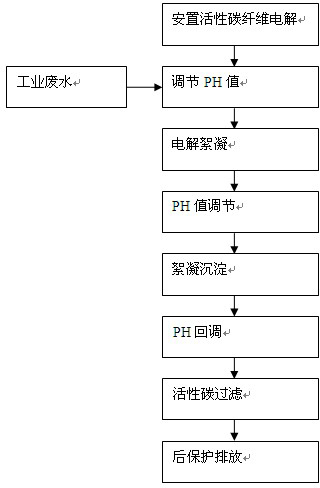

[0056] The above-mentioned waste water is treated with the application method of forming carbon according to the present invention in the treatment of industrial waste water by electrocoagulation. In step (2), the pH value of the waste water is adjusted to 3-4; in step (3), the electric The water quality after flocculation is 4-5; in step (4), the pH of the water is adjusted to 10-10.5; finally, after step (5) the electrocoagulation sedimentation is adjusted back in (6) and then discharged in (7) after filtration.

[0057] After described waste water is through above electrocoagulation process, the sampling analysis res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com