Composite cooking pot

A pot and pot body technology, which is applied to pressure cookers, cooking utensils, household appliances, etc., can solve the problems of worrying about the sealing of sockets, danger of electric shock, damage to electric heating tubes or electric heating films, etc., to ensure the safety and convenience of use, Ensure safety and convenience, and ensure the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

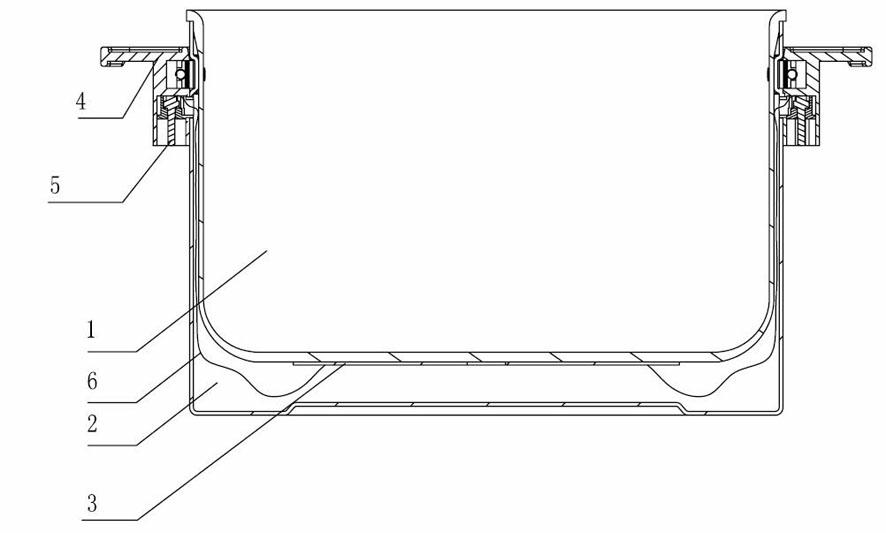

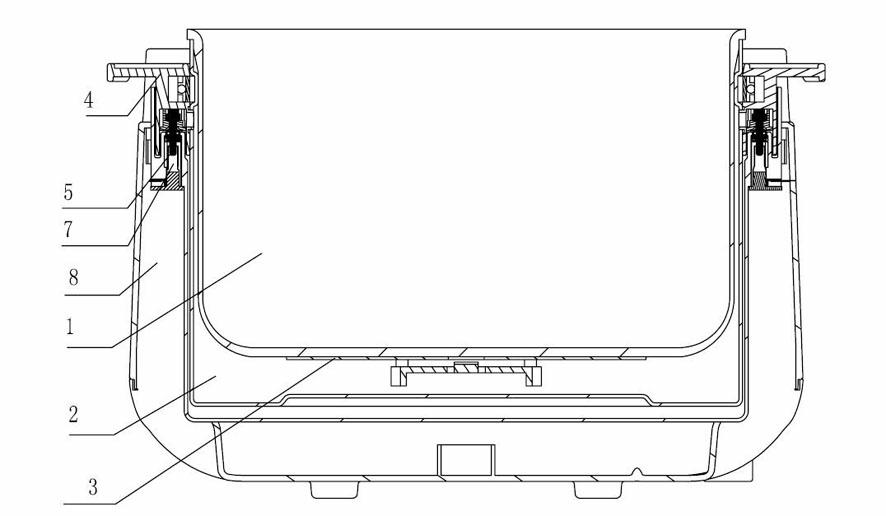

[0031] See figure 1 A composite cooking pot shown includes an inner pot body 1 and an electric heating element 3, the inner pot body is a concave container body having a pot wall and a pot bottom, an outer pot 2 is set on the outside of the inner pot body 1, and the outer pot 2 For blocking protective cover, the shape of outer pot 2 is consistent with existing pot body.

[0032] In this embodiment, the outer pot 2 is fixed and sealed to the inner pot body by welding, the mouth of the inner pot body 1 has a flange, the upper end of the outer pot 2 is fixed at the mouth of the inner pot body, and the electric heating element 3 is fixedly placed on the inner pot body and In the airtight cavity between the outer pots 2, the peripheral wall of the outer pot is provided with an electrical connector for electrically connecting the heating element with the mains power supply, and the electrical connector is installed on the side upper part of the pot body shielding protection cover. ...

Embodiment 2

[0039] In this embodiment, the electric heating element 3 is an electric heating plate, which is fixed on the bottom of the inner pot body, directly contacts with the inner pot, or is fixed on the inner surface of the outer pot, as long as it is placed in the airtight space between the inner pot body and the outer pot (shielding protective cover). within the cavity. All the other are with embodiment 1.

Embodiment 3

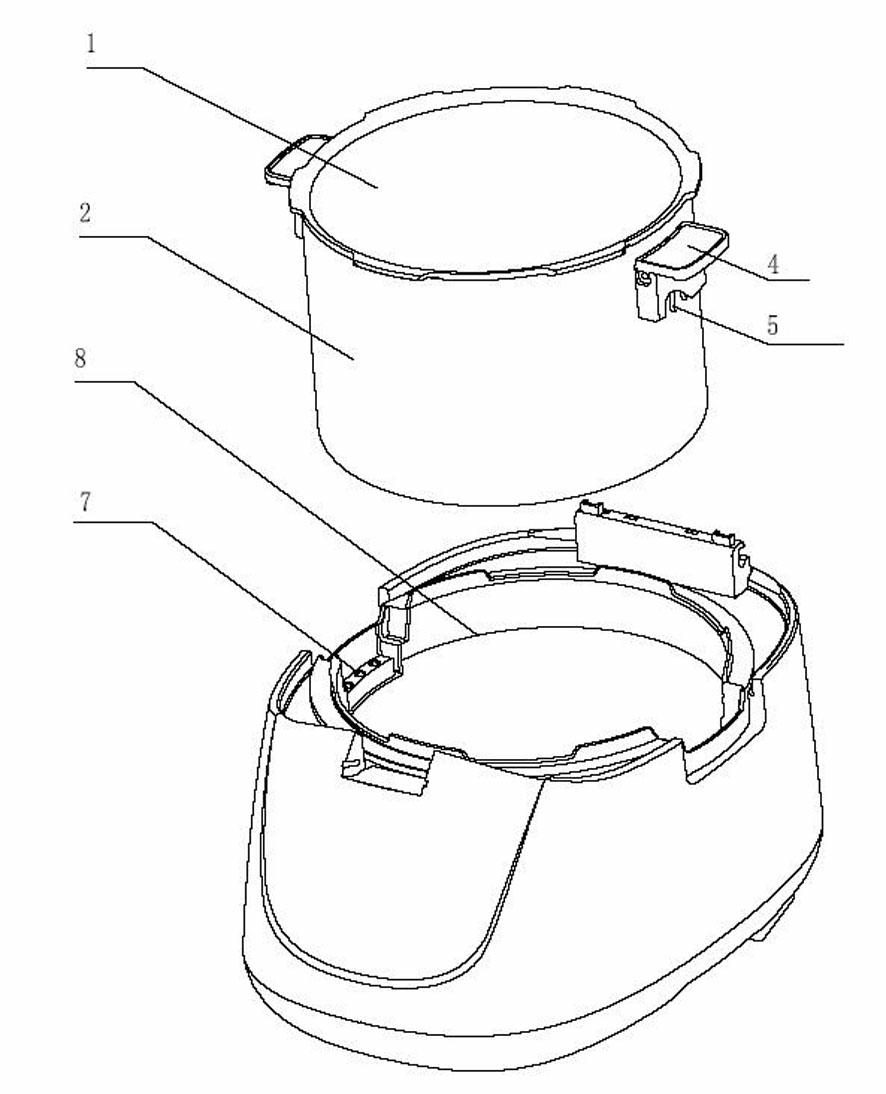

[0041] See Figure 5 Shown is the composite cooking pot of the present invention as a simple cooking utensil. Including an inner pot body 1 and an electric heating element 3, the inner pot body is a container body having a pot wall and a pot bottom, and an outer pot 2 is set on the outside of the inner pot body 1, and the outer pot 2 is a shielding cover. The outer pot in this embodiment 2. It is connected to the inner pot body through threads, and the joint is provided with a seal. The upper side of the outer pot is provided with an electrical connector 9 to realize the electrical connection between the heating element and the mains power supply. The position of the connector can be set according to the user's habits , about two-thirds of the height of the entire inner pot, when connected to an external power source through a power cord, it can be used as an easy-to-use self-heating pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com