Acoustic resonator and sound chamber

A technology of acoustic resonators and acoustic chambers, which is applied in the direction of sound-emitting devices, instruments, and sound absorption, and can solve problems such as difficulty in installing resonators and enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention will now be described in more detail by way of example with reference to the accompanying drawings, wherein like parts shown in the various drawings are indicated by like reference numerals.

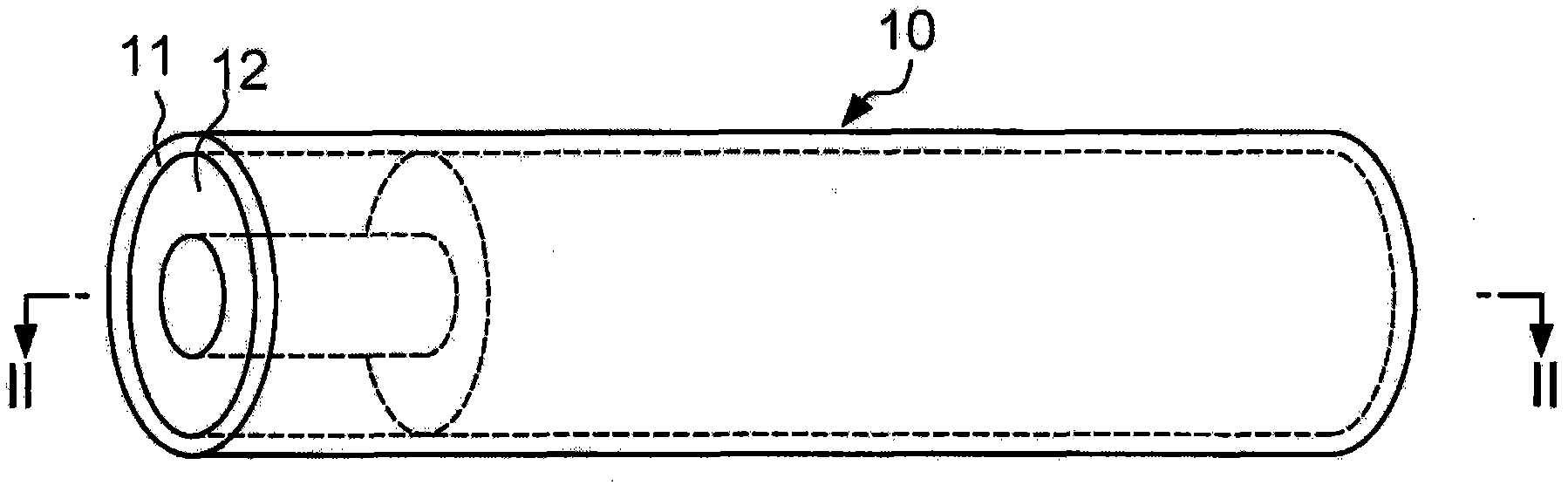

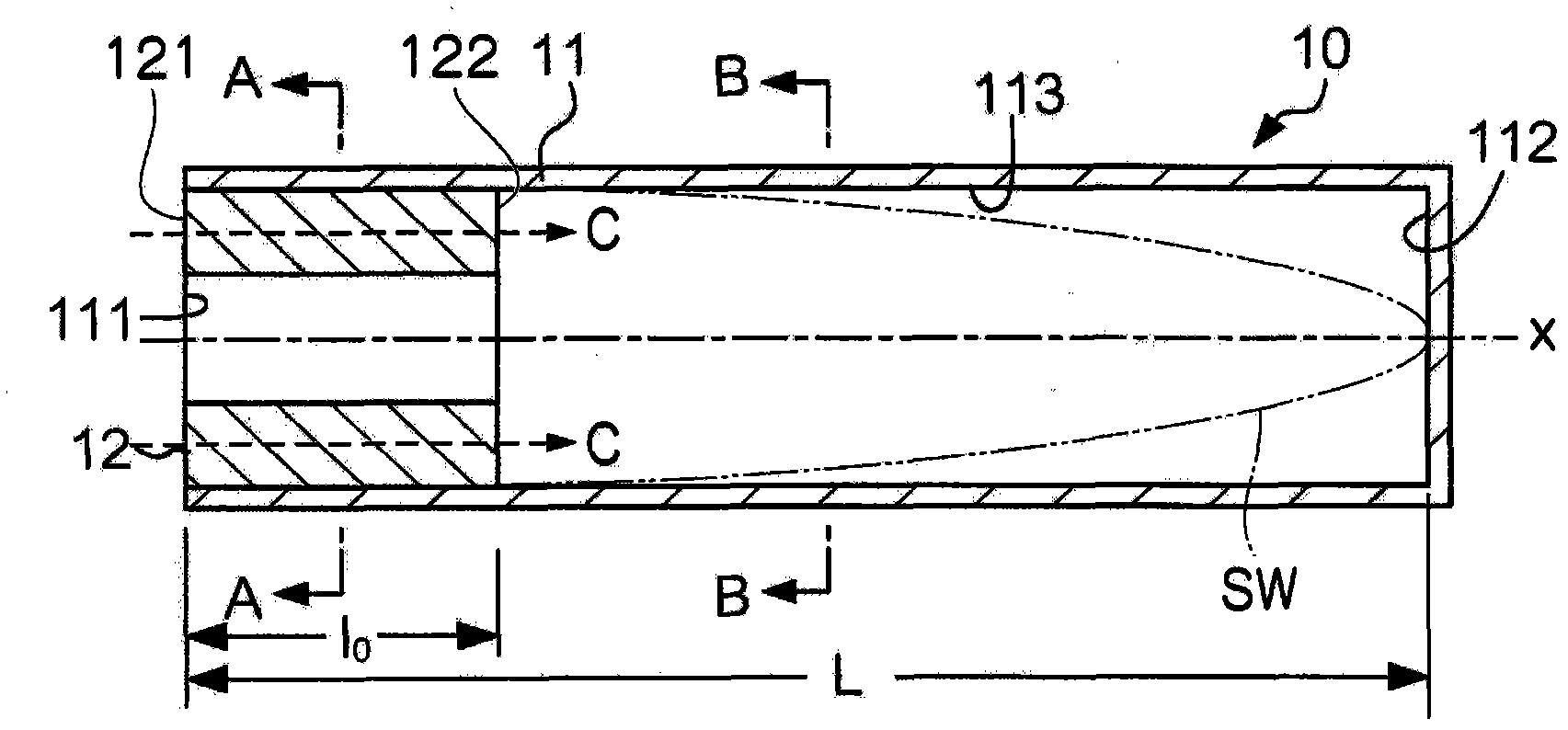

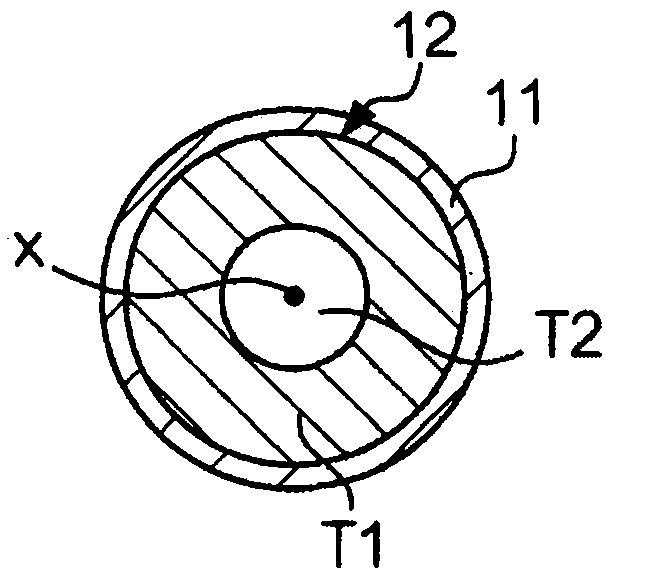

[0044] figure 1 is a perspective view of the acoustic resonator 10 according to the first embodiment of the present invention. The acoustic resonator 10 has the shape of a cylindrical tube with an open end (on the left) and an opposite closed end (on the right). The acoustic resonator 10 is divided into a pipe member 11 and a resistance member 12 . The pipe member 11 (serving as a housing of the acoustic resonator 10) is formed in a cylindrical shape and is made of metal or plastic. The pipe member 11 having one open end extends in the length direction. The resistance member 12 is a cylindrical assembly defined within opposing circular surfaces and having a cylindrical cavity therein lengthwise through the middle portion. The resistance member 12 is engaged insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com