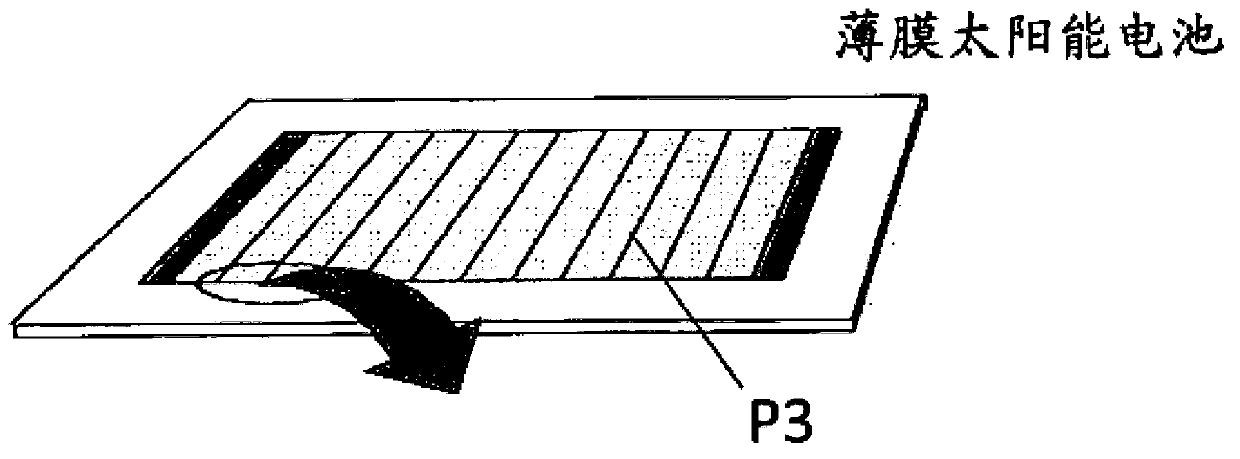

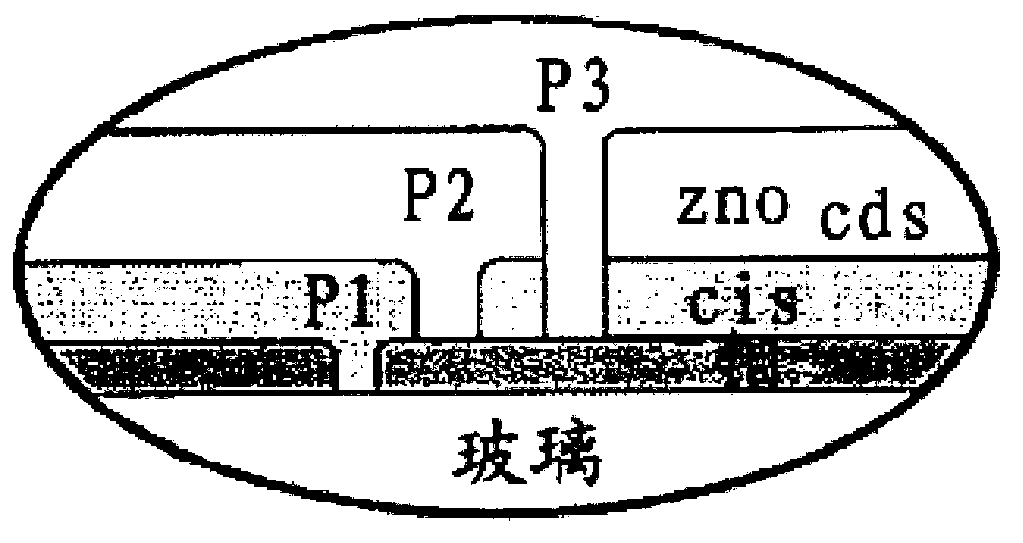

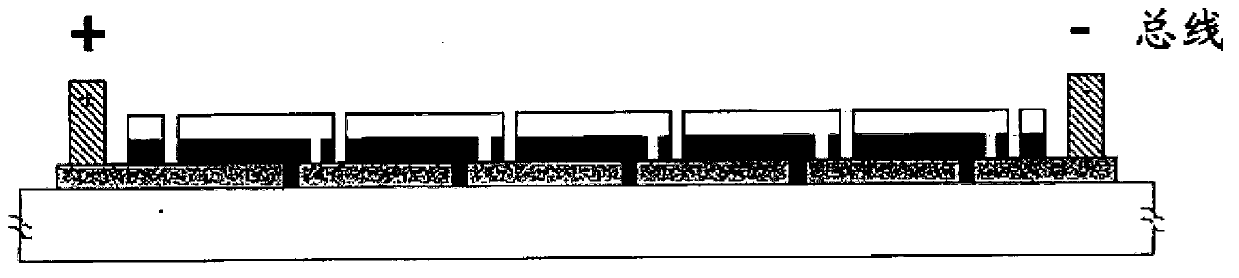

Method for forming thin film solar cell with buffer-free fabrication process

A technology of solar cells and thin films, applied in sustainable manufacturing/processing, final product manufacturing, circuits, etc., can solve the problems of passive, unable to provide sidewalls, etc., to achieve high energy output and increase solar energy conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] This illustrative description is intended to be read in conjunction with the accompanying drawings, which are to be considered a part of this entire specification. In the description of the embodiments disclosed herein, any expression of direction or orientation is merely for convenience of description, and is not intended to limit the scope of the present invention in any way. Related terms such as "lower", "upper", "horizontal", "vertical", "above", "below", "upper", "lower", "top", and "bottom" and their Variations of (eg, "horizontally," "downwardly," "upwardly," etc.) should be understood to refer to orientations as described thereafter or as shown in the figures in the discussion. These relative terms are for convenience of description only and do not require that the device be constructed or operated in a particular orientation. Unless otherwise stated, terms such as "attached," "mounted," "connected," and "interconnected" refer to a relationship in which struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com