Molded transformer provided with fire extinguishing device

A fire-extinguishing device and transformer technology, applied in transformer/inductor parts, transformer/inductor coils/windings/connections, electrical components, etc., can solve problems such as coil burnout, inoperability, component loss, etc., to achieve shortened piping, Rapid fire extinguishing effect and durability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

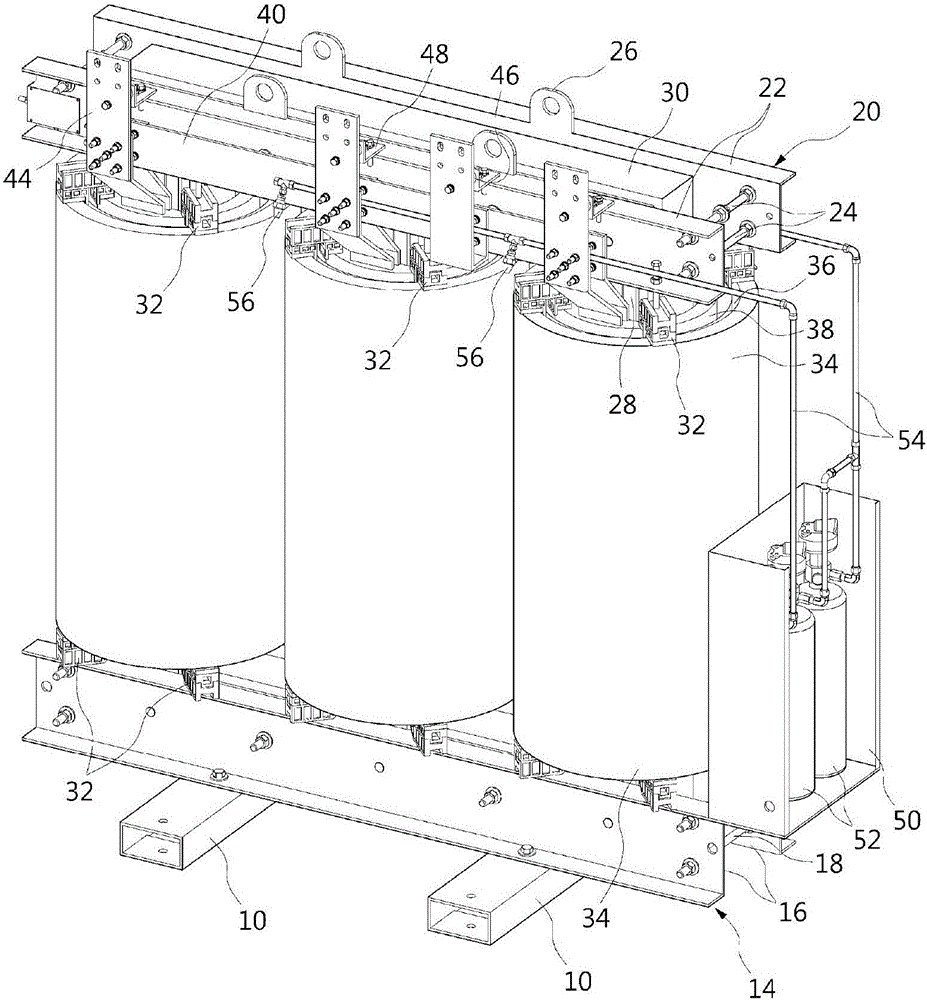

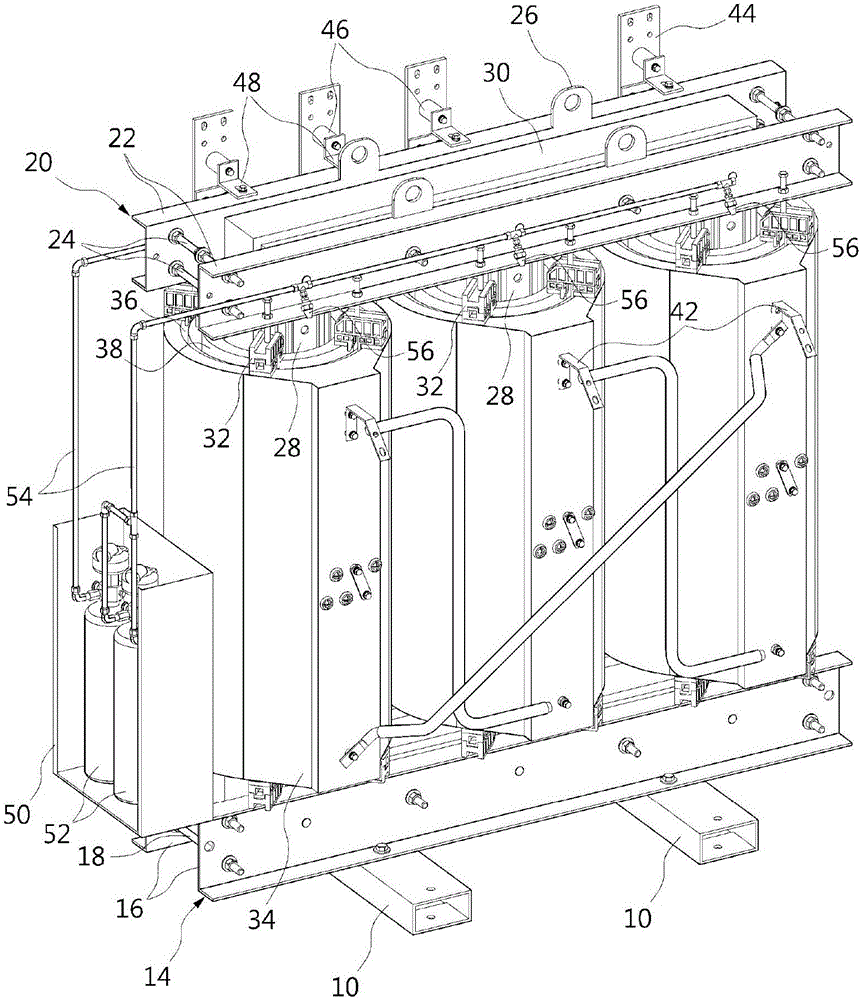

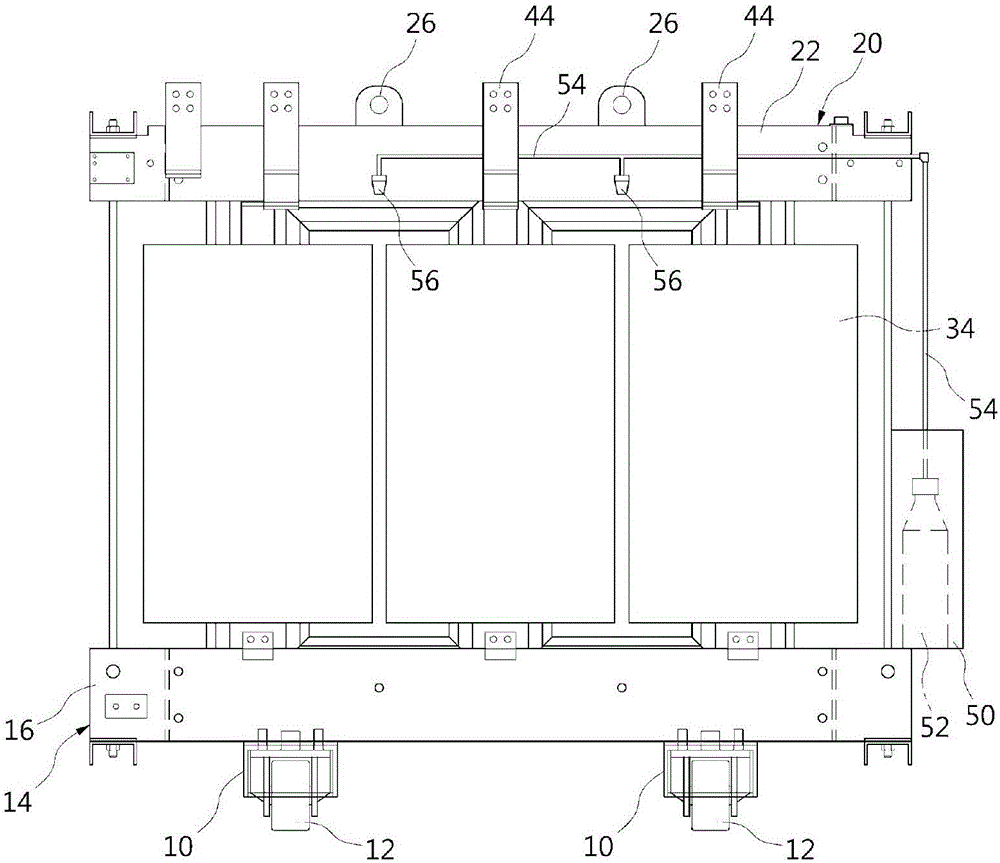

[0031] A part of embodiments of the present invention will be described in detail below with exemplary drawings. It should be noted that when assigning reference signs to constituent elements in each drawing, even if the same constituent elements are attached to different drawings, they should be given the same reference numerals as much as possible. In addition, when describing the embodiments of the present invention, if it is considered that the specific description of related known structures or functions hinders the understanding of the embodiments of the present invention, the detailed description thereof will be omitted.

[0032] In addition, terms such as first, second, A, B, a, b, etc. may be used when describing constituent elements of the embodiments of the present invention. Such terms are only used to distinguish the constituent element from another constituent element, and the nature or order or sequence of the constituent elements will not be limited by the term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com