High-speed pantograph head

A pantograph, high-speed technology, applied in the field of pantograph heads, can solve problems such as unfavorable dynamic current receiving, and achieve the effects of improving followability, reducing air resistance and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

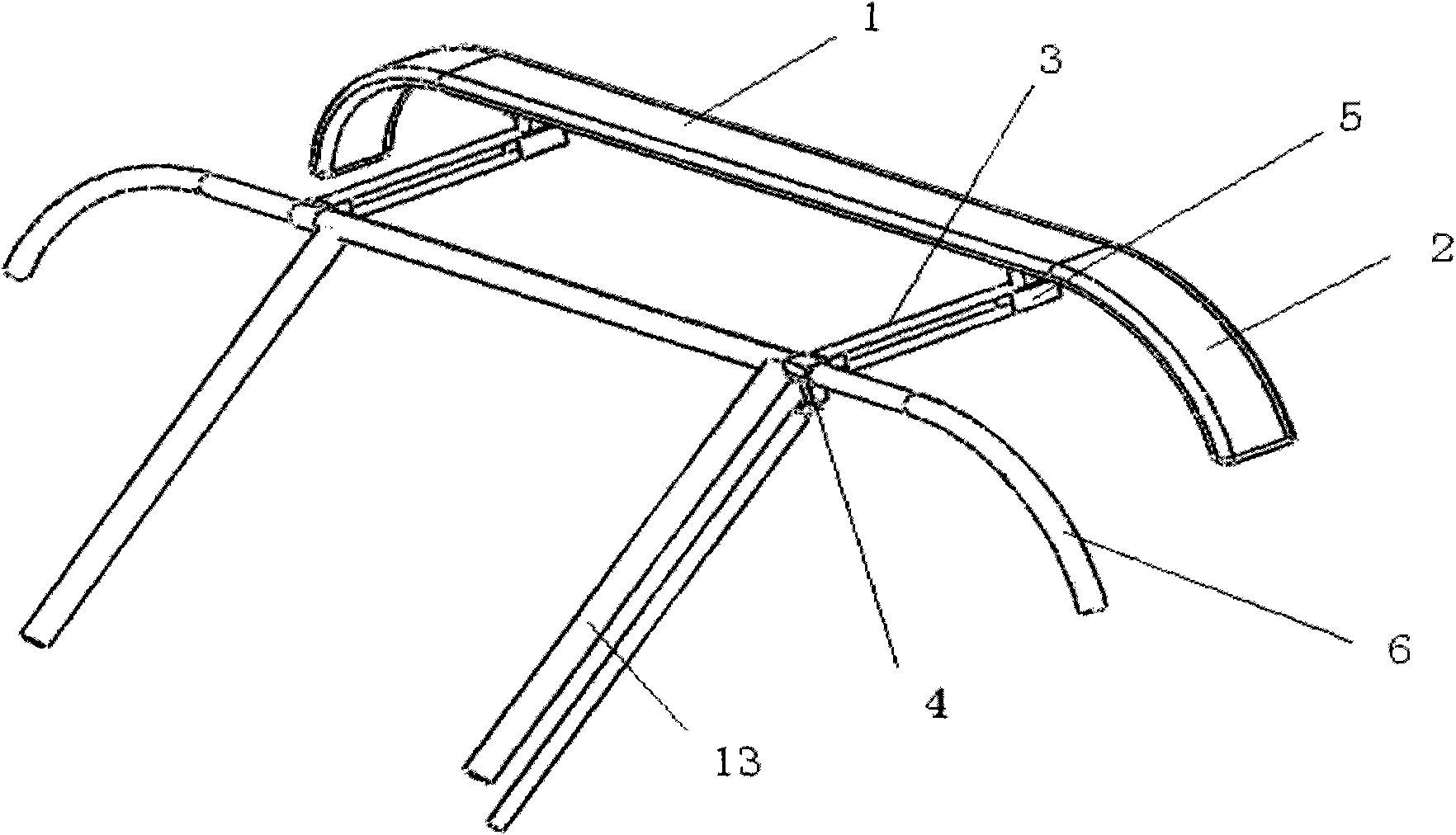

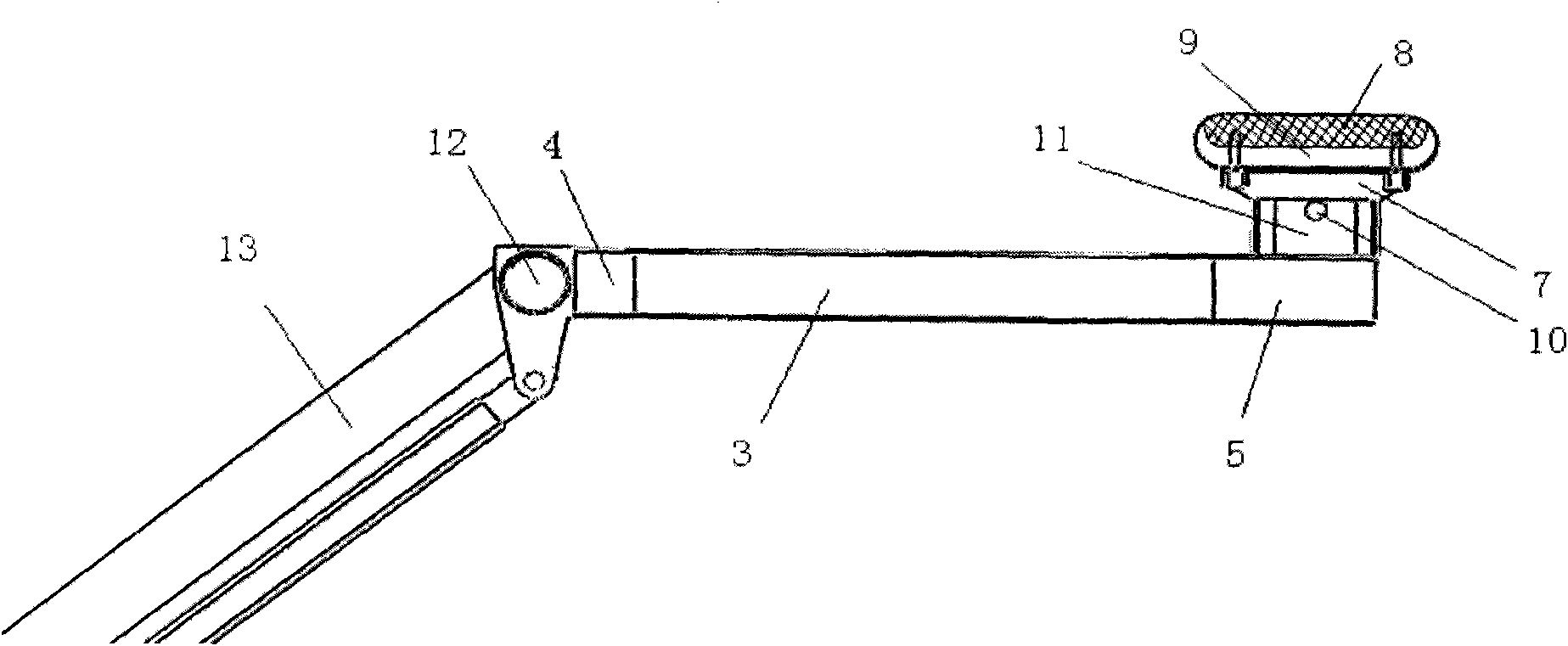

[0024] figure 1 and figure 2 Shown, the shape of the section of slide plate 1 is streamlined, and the bottom of slide plate 1 is a strip-shaped slide plate groove 9, and slide plate groove 9 is embedded with a carbon slide block 8 or powder metallurgy slide block, also can be other materials (such as powder metallurgy material), the slide plate groove 9 is connected to the bracket 7 by screws, the bracket 7 is connected to the support 11 on the front end 5 of the frame spring 3 by a pin 10, and the front end 5 of the frame spring 3 is fixedly connected to the support 11 , the rear end 4 of the frame spring 3 is fixedly connected to the hinge 12 of the double-rod upper frame 13 of the pantograph, the two ends of the slide plate 1 are provided with small bow horns 2, and the first big bow horn 6 is inserted and fixed on two In the hinge 12 of the frame 13 on the rod. The streamline shape of the cross section of the skateboard 1 is that the upper and lower sides are straight l...

Embodiment 2

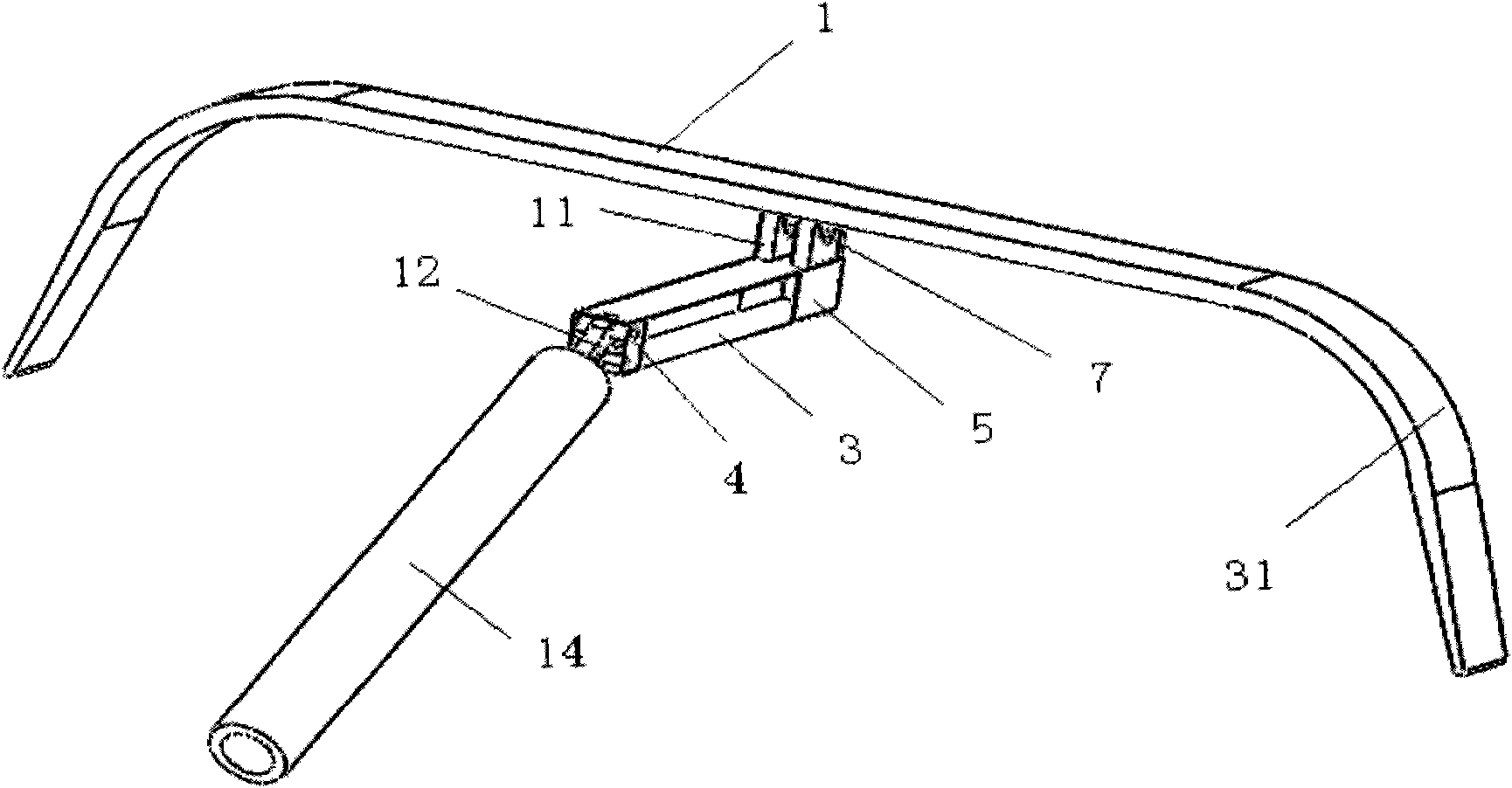

[0026] image 3 Shown, the shape of the section of slide plate 1 is streamlined, and the bottom of slide plate 1 is a strip-shaped slide plate groove 9, and slide plate groove 9 is embedded with a carbon slide block 8 or powder metallurgy slide block, also can be other materials (such as powder metallurgy material), the slide plate groove 9 is connected to the bracket 7 with screws, the center of the lower part of the bracket 7 is connected to the support 11 on the front end 5 of the frame spring 3 with a pin 10, and the front end 5 of the frame spring 3 is connected to the support 11 Fixed connection, the rear end 4 of the frame spring 3 is fixed on the hinge 12 of the single-rod upper frame 14 of the pantograph, and the two ends of the slide plate 1 are provided with a second large bow angle 31 . The streamline shape of the cross section of the skateboard 1 is that the upper and lower sides are straight lines, and the left and right ends are elliptical or circular.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com