Method for preparing big-diameter granules from micro and nano powder by means of interfacial polymerization

An interfacial polymerization, micro-nano technology, used in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of difficult to control the internal porosity of particles, poor sphericity and surface finish, and uneven particle size, and achieve true sphericity. High, wide particle size range, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

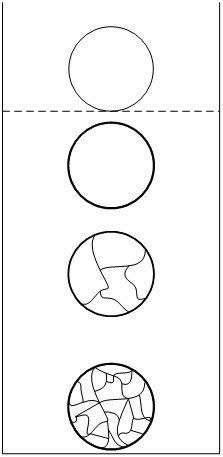

Image

Examples

Embodiment 1

[0028] Preparation of 1.90mm large particles by nano-silica:

[0029] 1. Disperse 15g of nano-silica and 25g of triethylenetetramine in 100mL of water, and stir for 10 minutes at a speed of 5000r / min with a high-shear dispersing emulsifier;

[0030] 2. Add 42g of glycerol glycidyl ether and 15g of acid absorbing agent sodium carbonate into 100mL water, fully dissolve;

[0031] 3. Configure 2000mL terephthaloyl chloride n-hexane supersaturated solution, the liquid level height is 500mm, and the temperature is kept at 50°C;

[0032] 4. After quickly mixing the solutions prepared in steps 1 and 2, add the terephthaloyl chloride n-hexane supersaturated solution prepared in step 3 dropwise through a sieve plate with an aperture of 0.84 mm, and granulate while the droplets fall to the bottom .

[0033] After separation, the average particle size of the prepared spherical particles is 1.90mm, and the porosity is 40%.

Embodiment 2

[0035] Preparation of 3.04 mm Large Particles of Halloysite Nanotubes

[0036] 1. Disperse 15g of halloysite nanotubes and 15g of polyethyleneimine in 100mL of water, and stir at a speed of 5000r / min for 10 min with a high-shear dispersing emulsifier;

[0037] 2. Add 20g of glycerol glycidyl ether and 15g of sodium carbonate into 100mL of water, fully dissolve;

[0038] 3. Configure 2000mL hexamethylene diisocyanate toluene supersaturated solution, the liquid level height is 500mm, and the temperature is kept at 80°C;

[0039] 4. After quickly mixing the solutions prepared in steps 1 and 2, add the hexamethylene diisocyanate toluene supersaturated solution prepared in step 3 dropwise through a sieve plate with an aperture of 1.36 mm, and granulate while the droplets fall to the bottom.

[0040] After separation, the average particle size of the prepared spherical particles is 3.04mm, and the porosity is 48%.

Embodiment 3

[0042] Preparation of 3.04 mm Large Particles of Modified Halloysite Nanotubes

[0043] 1. Take 20g of halloysite nanotubes calcined at 400°C for 5h, reflux in the toluene solution of silane coupling agent Z6020 for 48h, and vacuum-dry after centrifugation;

[0044] 2. Disperse 15 g of the modified halloysite nanotubes and 15 g of polyethyleneimine prepared in step 1 in 100 mL of water, and stir for 10 min at a speed of 5000 r / min with a high-shear dispersing emulsifier;

[0045] 3. Add 20g of glycerol glycidyl ether and 15g of sodium carbonate into 100mL of water, fully dissolve;

[0046] 4. Configure 2000mL hexamethylene diisocyanate toluene supersaturated solution, the liquid level height is 500mm, and the temperature is kept at 80°C;

[0047] 5. After quickly mixing the solutions prepared in steps 2 and 3, add the hexamethylene diisocyanate toluene supersaturated solution prepared in step 4 dropwise through a sieve plate with an aperture of 1.36 mm, and granulate while th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com