Method and device for producing high-pressure nitrogen and low-pressure oxygen

A production method, low-pressure oxygen technology, applied in refrigeration and liquefaction, lighting and heating equipment, liquefaction, etc., can solve the problems of low purity of nitrogen and oxygen products, complex refrigeration and cooling process, low production efficiency, etc., and achieve high extraction rate, Realize the effect of circular economy and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

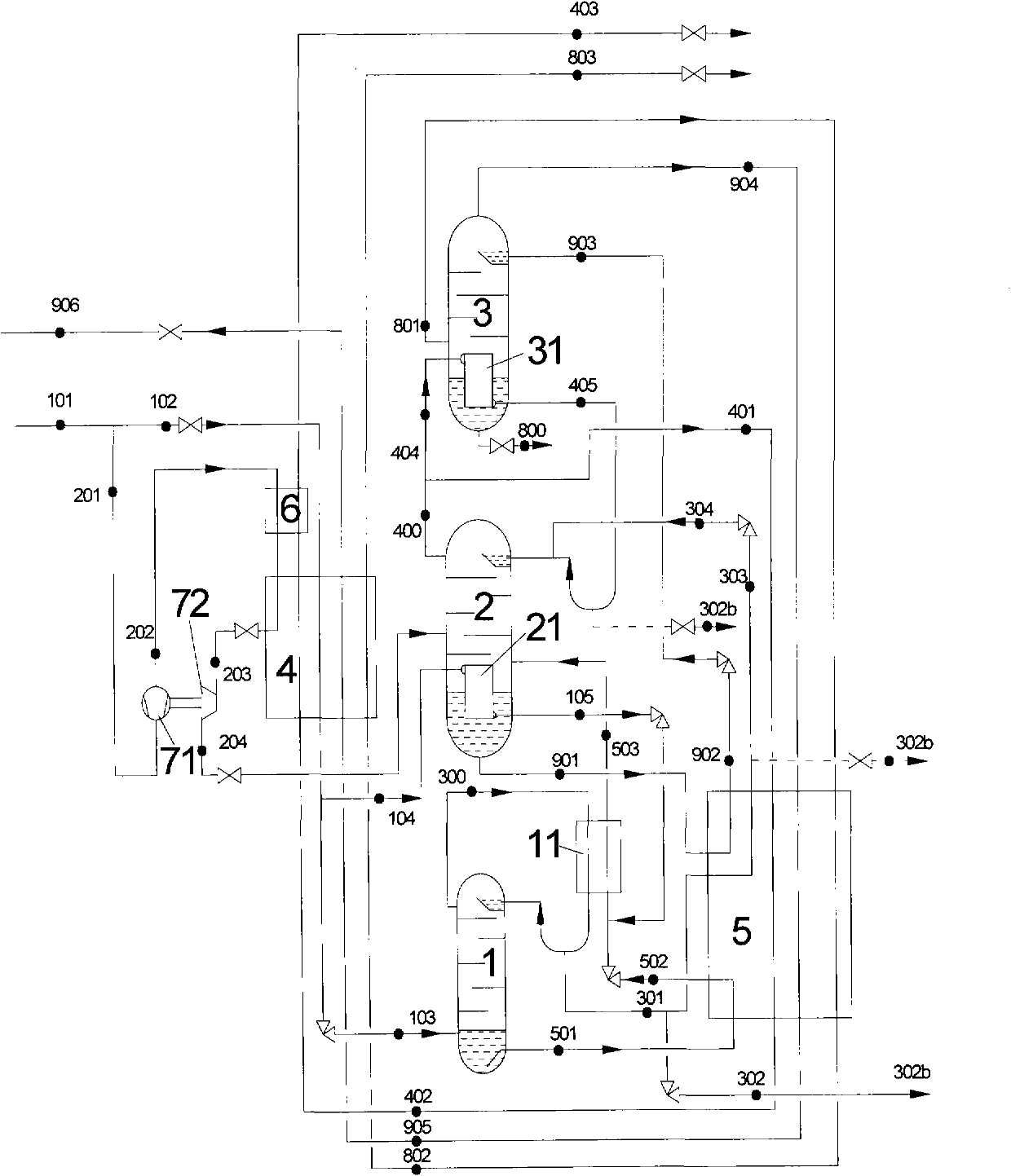

[0043] Such as figure 1 Shown: the present invention adopts the method for rectification of three towers to produce high pressure nitrogen and low pressure oxygen simultaneously, and described three rectification towers are high pressure tower 1, nitrogen tower 2 and oxygen tower 3, and described high pressure tower 1, oxygen tower 3 are all Connect with condensing evaporator, the condensing evaporator 11 of high-pressure tower 1 is arranged outside described high-pressure tower 1, and the condensing evaporator 31 of described oxygen tower 3 is installed in the tower kettle of described oxygen tower 3, and described nitrogen tower 2 is equipped with a reboiler 21, and the production device of the present invention also includes a main heat exchanger 4, a subcooler 5, and a cooler 6. Its device structure and production steps for producing high-pressure nitrogen and low-pressure oxygen are as follows:

[0044] The first raw air inlet of the main heat exchanger 4 is connected wi...

Embodiment 2

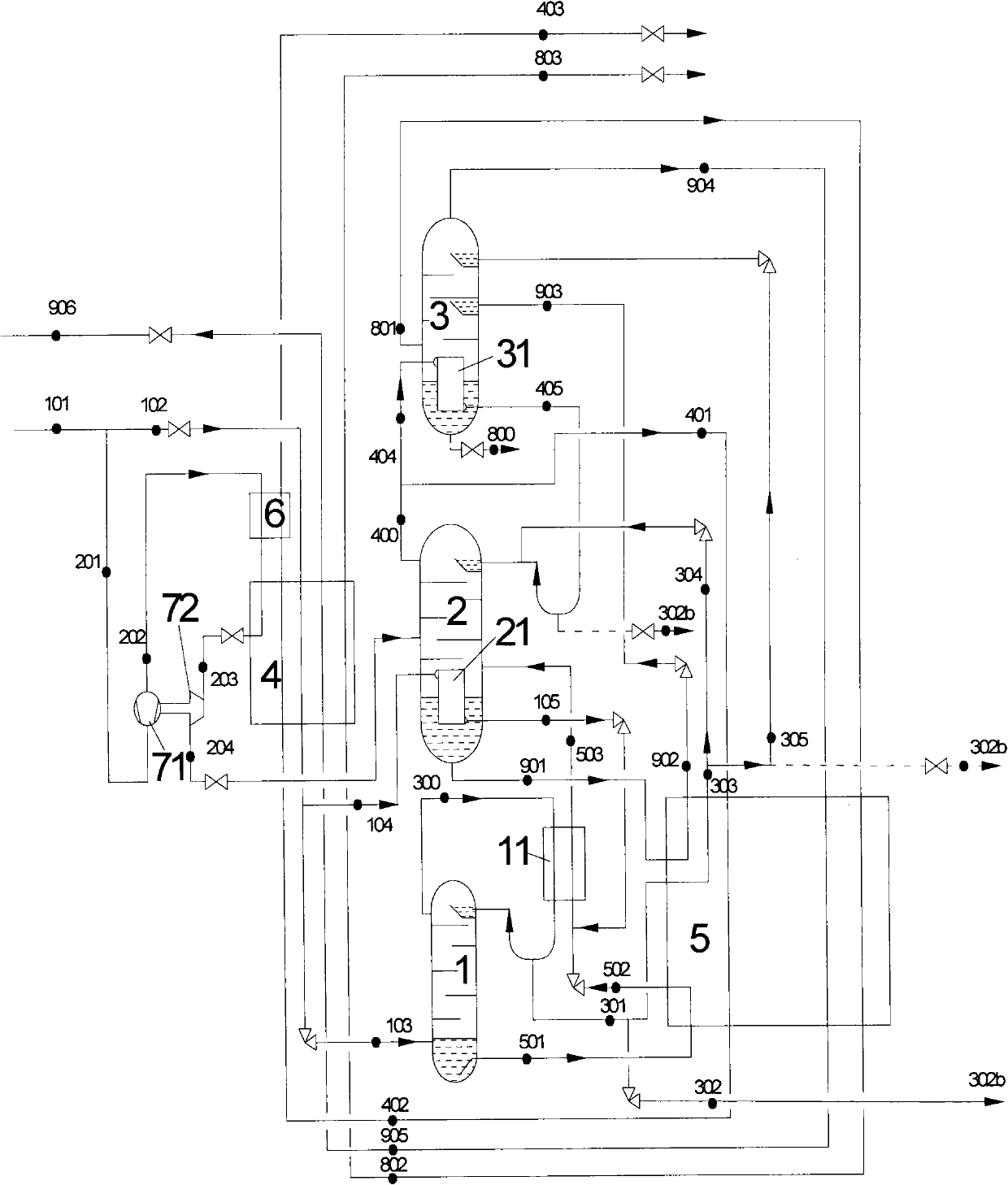

[0056] A production method of high-pressure nitrogen and low-pressure oxygen, on the basis of the process for preparing high-pressure nitrogen and low-pressure oxygen in Example 1, the oxygen-enriched liquid air 903 produced by the nitrogen tower is passed into the middle of the oxygen tower 3 . And the high-pressure tower liquid nitrogen 303 of described after cooler 5 is divided into two parts, liquid nitrogen 304 and liquid nitrogen 305, described liquid nitrogen 305 throttling through throttle valve, after its pressure is adjusted to the pressure of oxygen tower 3, send Into the top of the oxygen tower 3 as reflux liquid. The structure of the device used is as figure 2 As shown, the upper section of the oxygen tower 3 is provided with a reflux liquid inlet, and the reflux liquid inlet is connected with the liquid nitrogen outlet of the condensing evaporator of the oxygen tower 3, and the liquid nitrogen 305 is passed from the liquid nitrogen at the top of the oxygen tower...

Embodiment 3

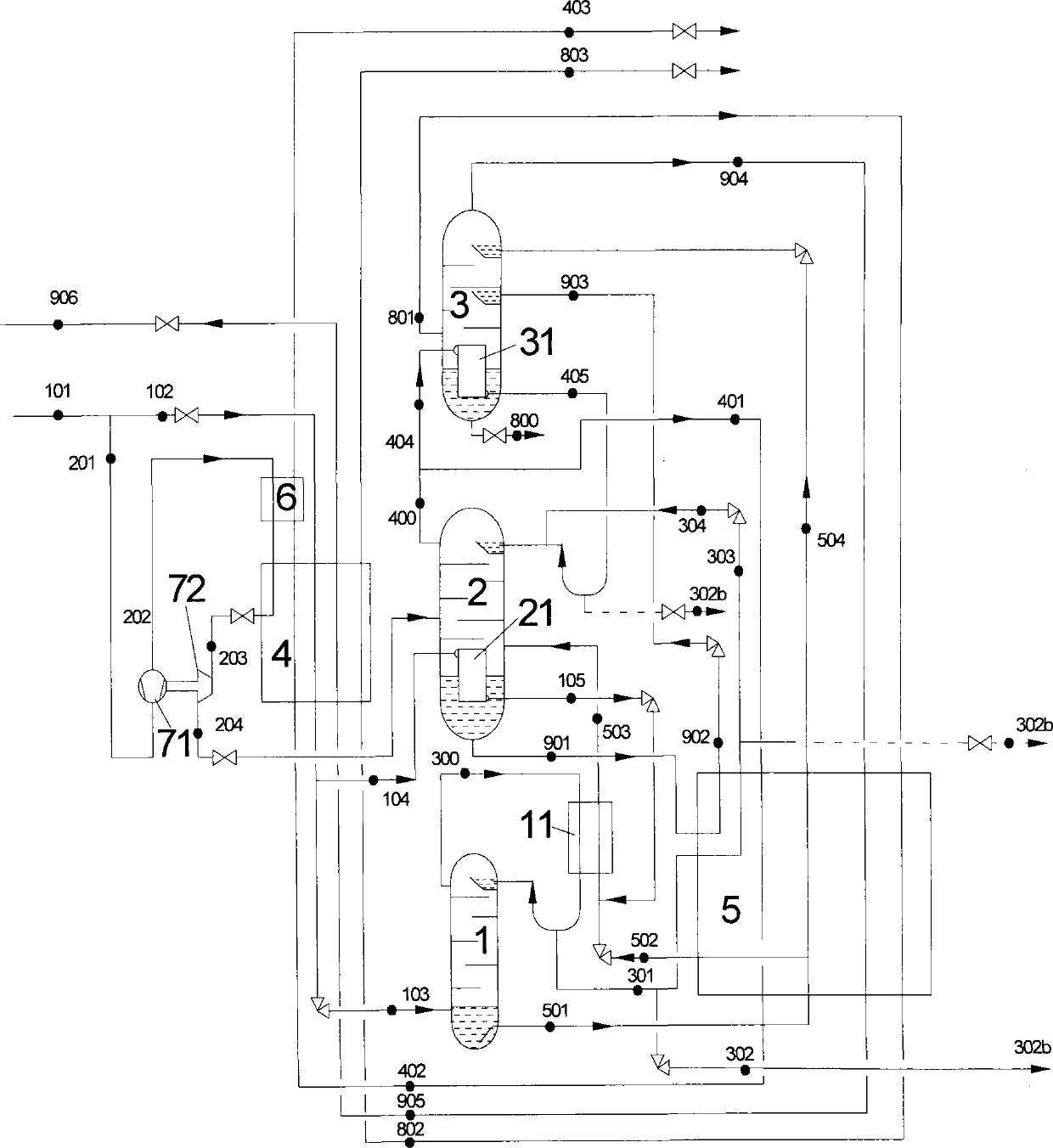

[0058] A method for producing high-pressure nitrogen and low-pressure oxygen. On the basis of the process for preparing high-pressure nitrogen and low-pressure oxygen in Example 1, the oxygen-enriched liquid air 903 generated by the nitrogen tower is passed into the middle of the oxygen tower 33 . And the oxygen-enriched liquid 501 leaves the high-pressure tower 1, and the oxygen-enriched liquid obtained after entering the subcooler 5 is divided into two streams of oxygen-enriched liquid 502 and 504, and the oxygen-enriched liquid 502 enters the high-pressure tower 1, another stream of oxygen-enriched liquid 504 is adjusted to the pressure of the oxygen tower 3 through a throttle valve, and then sent into the oxygen tower 3 as a reflux liquid. The structure of the device used is as image 3 As shown, the oxygen tower 3 is also provided with a reflux liquid inlet, and the reflux liquid inlet is connected to the oxygen-enriched liquid output port of the high pressure tower 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com