Diamond-filled isotropical high-performance heat-conductive adhesive and preparation method thereof

An isotropic, high-performance technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor thermal conductivity, low density, low thermal conductivity, etc. Harsh, simple preparation method, high bond strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

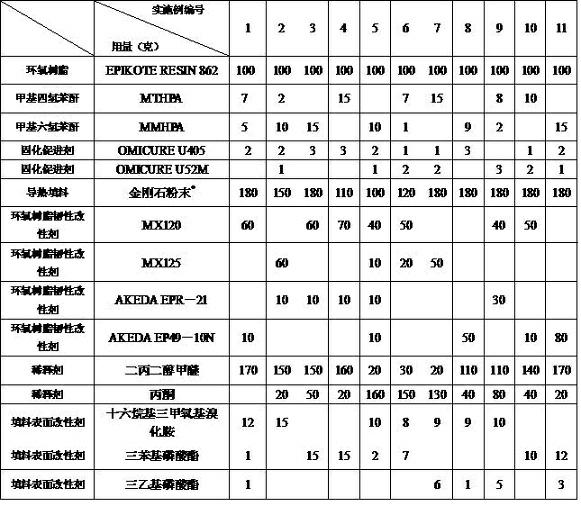

Embodiment 1~11

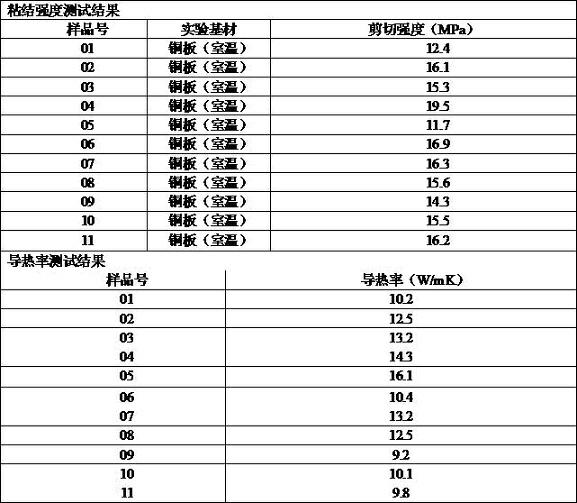

[0027] Prepare the colloid by the quality given in Table 1, and the specific preparation process is: epoxy resin, epoxy toughness modifier are mixed, and the mode of mixing is mechanical stirring, and stirring rate is 1500 rev / mins, and the time is 20 minutes, then Add diamond heat-conducting filler, filler surface modifier, and diluent to it while stirring, and continue stirring for 15 minutes after the addition is complete. After mixing evenly, add curing agent and curing accelerator to the mixture, mechanically stir the mixture for 5 minutes Transfer to a high-speed shear mixer for mixing, the mixing rate is 2000 rpm, and the time is 30s. Repeat the mixing process in the high-speed shear mixer 3 times to obtain a uniformly mixed jelly, which is the thermally conductive adhesive.

[0028] The bonding strength is prepared according to JISK6580 (Japanese Industrial Standards), using aluminum plate as the substrate, and the sample is a single-sided lap joint test piece, L=12.5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com