Laminated ternary positive material and preparation method thereof

A cathode material and layered technology, applied in the field of layered ternary cathode materials and their preparation, can solve the problems of low "energy/price" value, complicated preparation process, expensive price, etc., and achieve high consistency and high energy density , The effect of reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

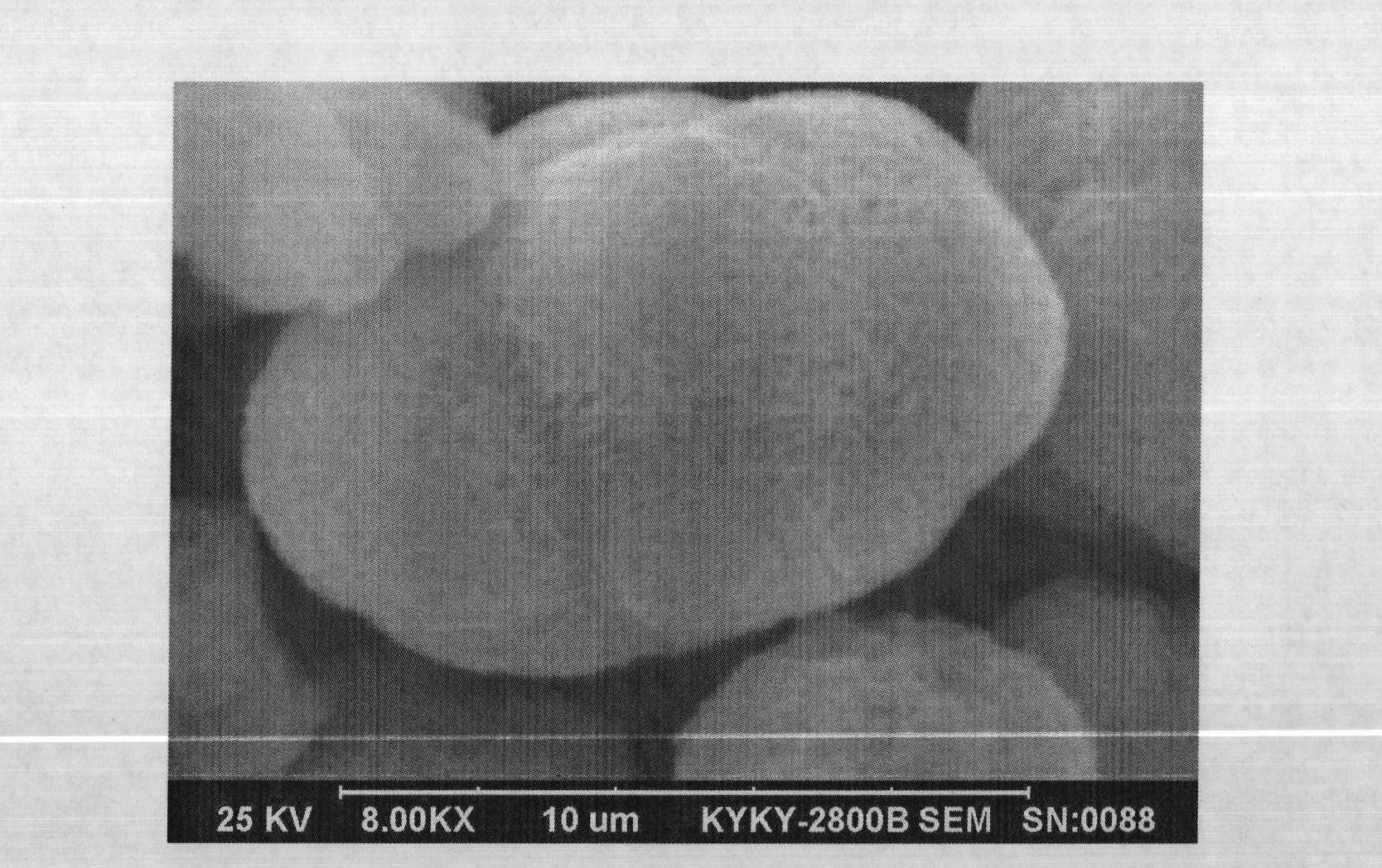

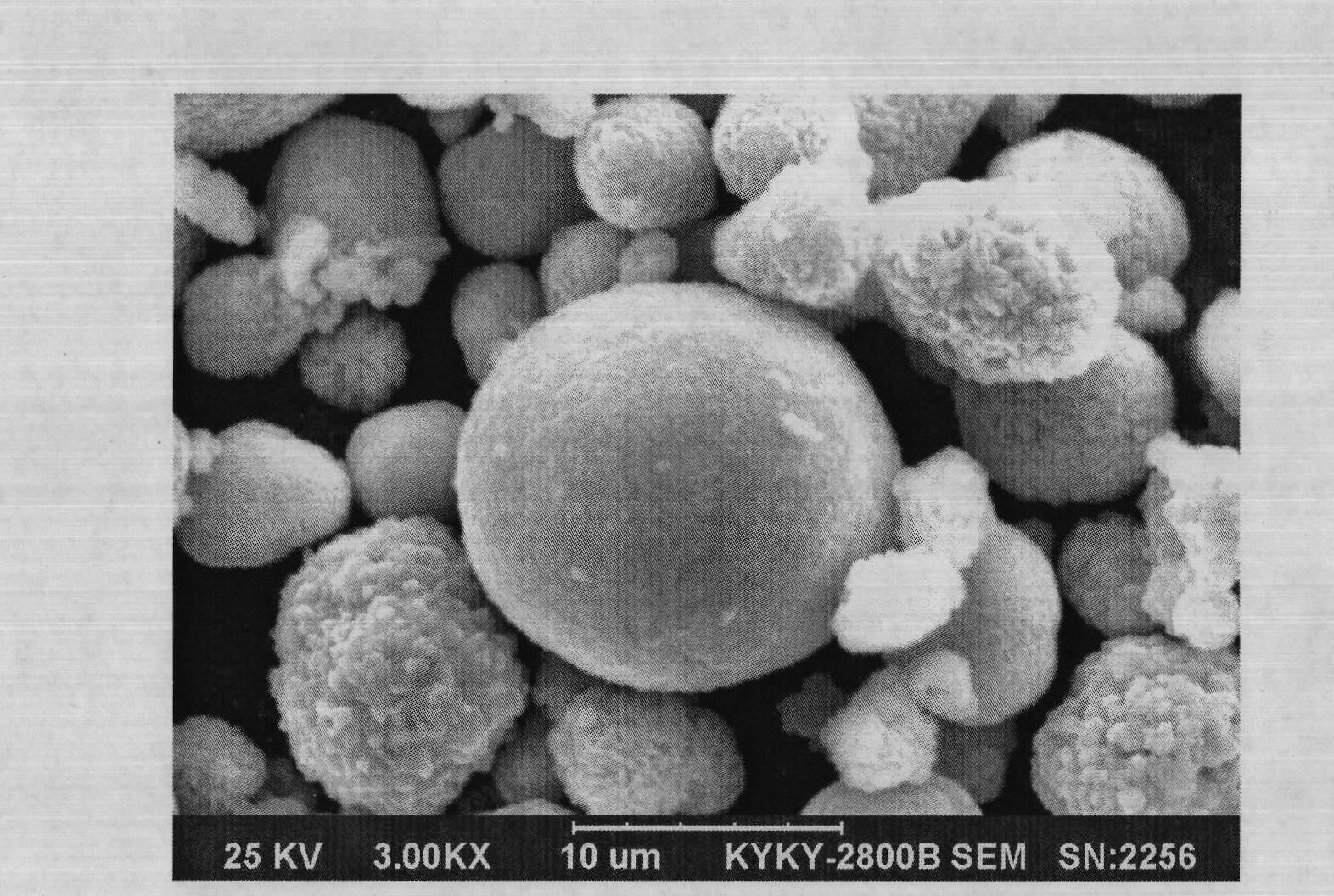

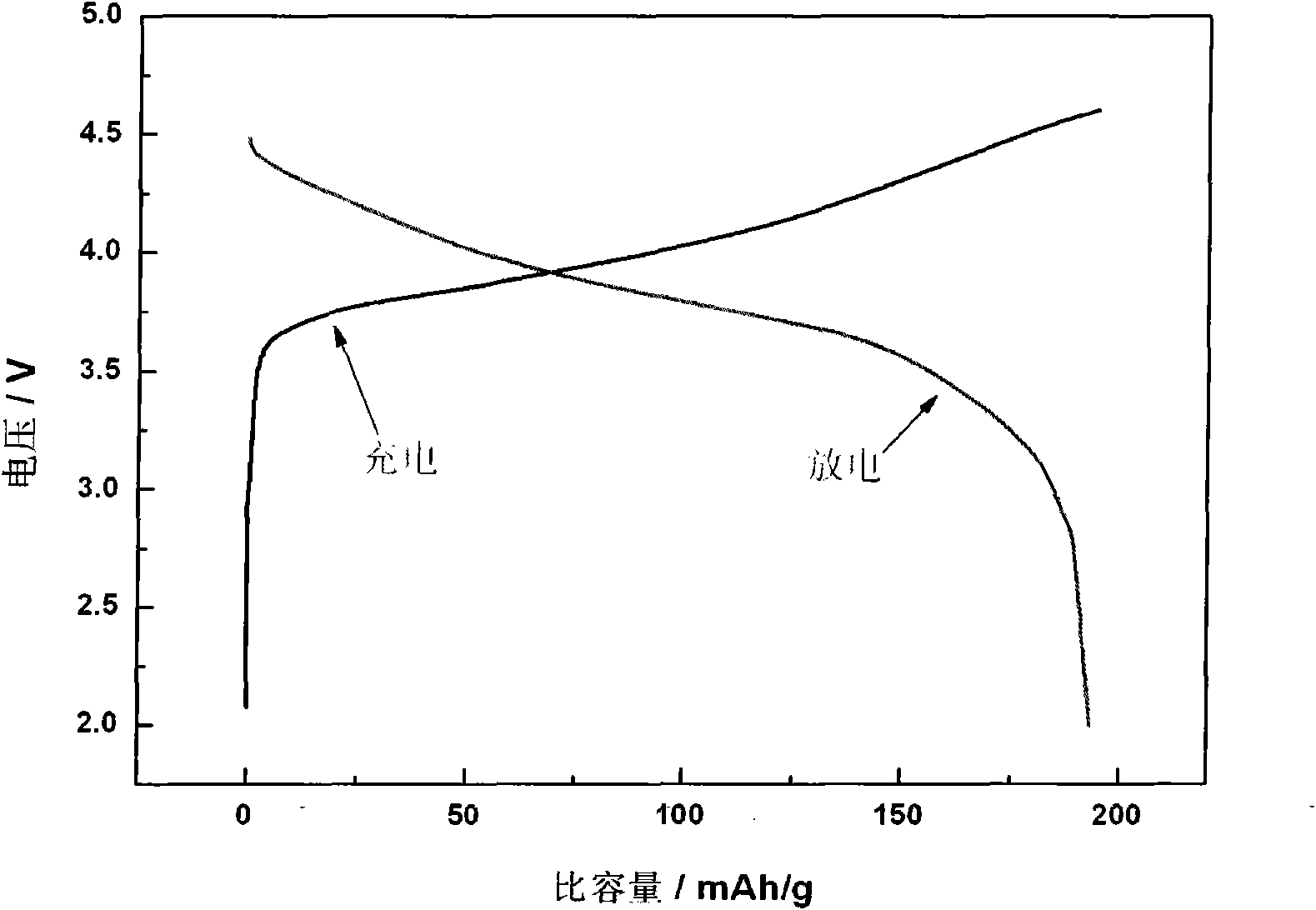

[0016] In summary, the preparation method of the layered ternary cathode material according to the present invention includes steps: step 1: preparing a precursor mixture with spheroidization; step 2: sintering the spheroidization precursor mixture to synthesize aLi 2 MnO 3 ·(1-a)LiMn (1-x-y) Ni x co y o 2 positive electrode material, where 02 MnO 3 ·(1-a)LiMn (1-x-y) Ni x co y o 2 / M layered ternary cathode material, where M is Al 2 o 3 、TiO 2 , ZrO 2 , La 2 o 3 , ZnO or MgO, the layered ternary positive electrode material has a layered structure of R-3m space group, contains three elements of nickel, cobalt and manganese, and has a spherical shape, an approximate spherical shape, a diamond shape, and a cone shape with a long-short axis ratio of 1 to 5 , flaky, layered or blocky microscopic features, with a particle size of 5-40 μm and a specific surface area of 0.2-10 m 2 / g.

[0017] In the preparation method of the layered ternary cathode material accordi...

Embodiment 1

[0045]The speed 50L / h that solution injects reactor, sodium hydroxide 2mol / L, nickel sulfate 2.33mol / L, manganese sulfate 5.33mol / L, cobalt sulfate 2.33mol / L, additive hydrazine 1wt%, press precursor (nickel+cobalt + manganese): the molar ratio of lithium is 0.77:1, the rotating speed of the ball mill is 200r / min, and the time is 2h to obtain the spheroidized precursor mixture; Speed, heating up to 950°C, sintering for 10h, continuously feeding dry oxygen during the sintering process, flow rate 500mL / min, to obtain 0.3Li 2 MnO 3 0.7LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 Positive electrode material: put the obtained positive electrode material in a box furnace, heat up to 600°C at a heating rate of 5°C / min, keep it warm for 10h, and then naturally cool to room temperature, and then crush, classify, and sieve; titanate Dissolved in ethanol, converted into corresponding oxides accounted for 0.5% of the mass of the positive electrode material, slowly added the crushed, sieved, and classi...

Embodiment 2

[0047] The speed 100L / h that solution injects reactor, potassium hydroxide 8mol / L, nickel chloride 6mol / L, manganese chloride 8mol / L, cobalt chloride 6mol / L, additive ethylenediamine 2wt%, press precursor (nickel + cobalt + manganese): the molar ratio of lithium is 0.91:1, the rotating speed of the ball mill is 100r / min, and the time is 40h to obtain the spheroidized precursor mixture; The heating rate is increased to 700°C, sintered for 24 hours, and dry air is continuously introduced during the sintering process, the flow rate is 1000mL / min, and 0.1Li 2 MnO 3 0.9LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 Positive electrode material: put the obtained positive electrode material in a box furnace, heat up to 500°C at a heating rate of 10°C / min, keep it warm for 24h, and then naturally cool to room temperature, and then crush, classify, and sieve; the zirconate Dissolved in acetone, converted into corresponding oxides accounted for 5% of the mass of the positive electrode material, slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com