Manufacturing method for electrode slice and electrode slice

A manufacturing method and electrode sheet technology, applied in battery electrodes, alkaline storage battery electrodes, circuits, etc., can solve the problems of poor performance of large current, micro-cracks in electrode sheets, and non-soft electrode sheets, and achieve smooth surface and internal resistance. Small, homogeneous effect of active substance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

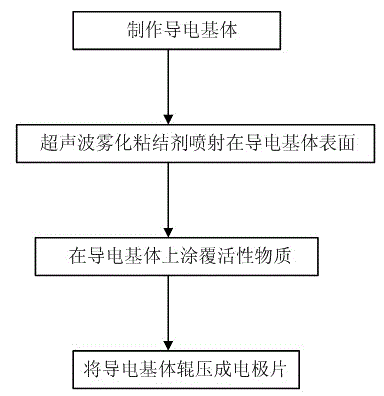

[0025] like figure 1 As shown, it is a flow chart of the manufacturing method of the electrode sheet in this specific embodiment, including the following steps:

[0026] 1) Make a conductive substrate. The conductive substrate is continuous nickel foam. Preferably, the thickness, surface density and porosity of the continuous nickel foam surface are consistent.

[0027] 2) The binder solution is atomized by ultrasonic waves, and the binder solution is sprayed onto the surface of the conductive substrate.

[0028] Wherein, the mass fraction of the binder in the binder solution is 0.5%-30%.

[0029] The binder components in the selected binder solution include hydrophilic binders and hydrophobic binders. This is because the hydrophilic binder has a good binding effect, and the active material will not fall off fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com