Container cleaning-drying and filling-sealing interlocking machine set control system

A unit control and container technology, applied in the field of control systems, can solve the problems of poor electrical performance consistency of the electronic control system, no real-time working condition display function, lack of electronic signature function, etc., to save assembly space, no current impact, and integration. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

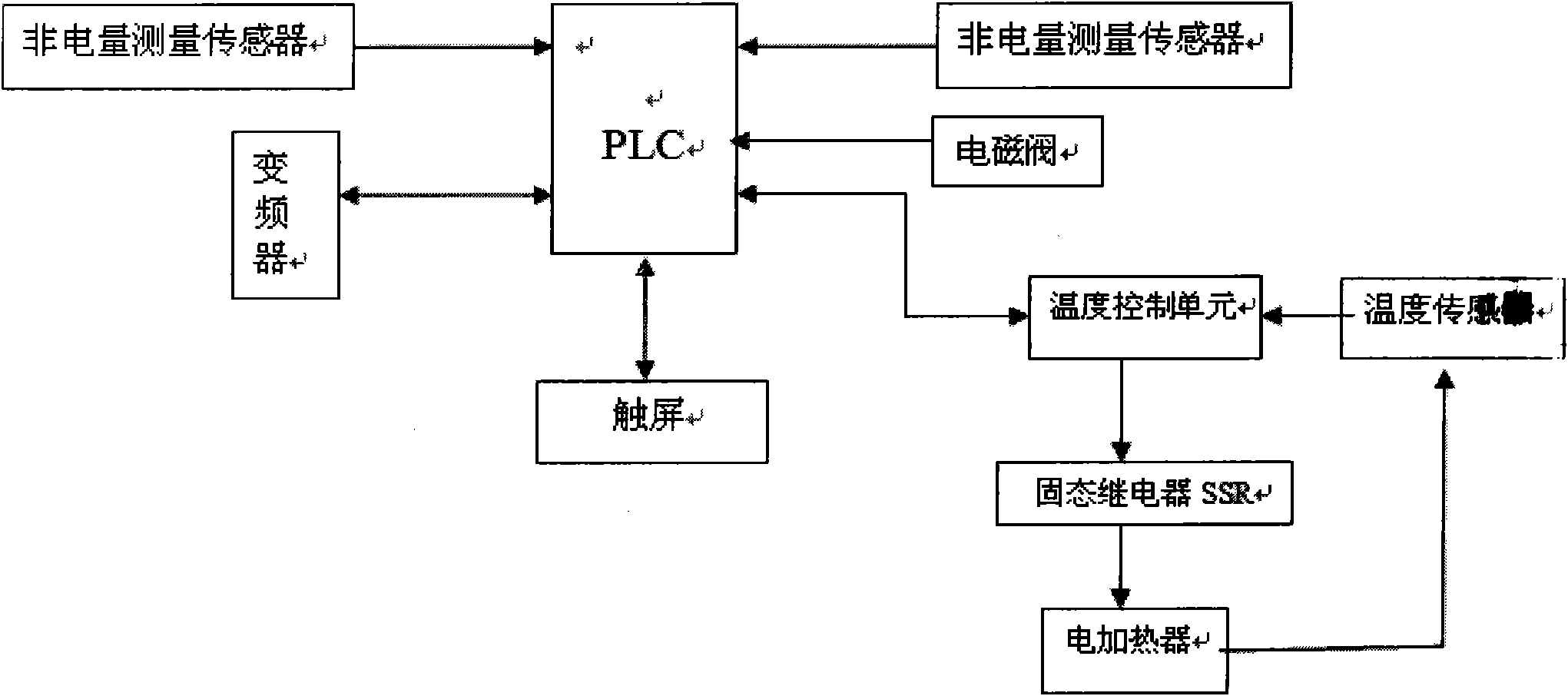

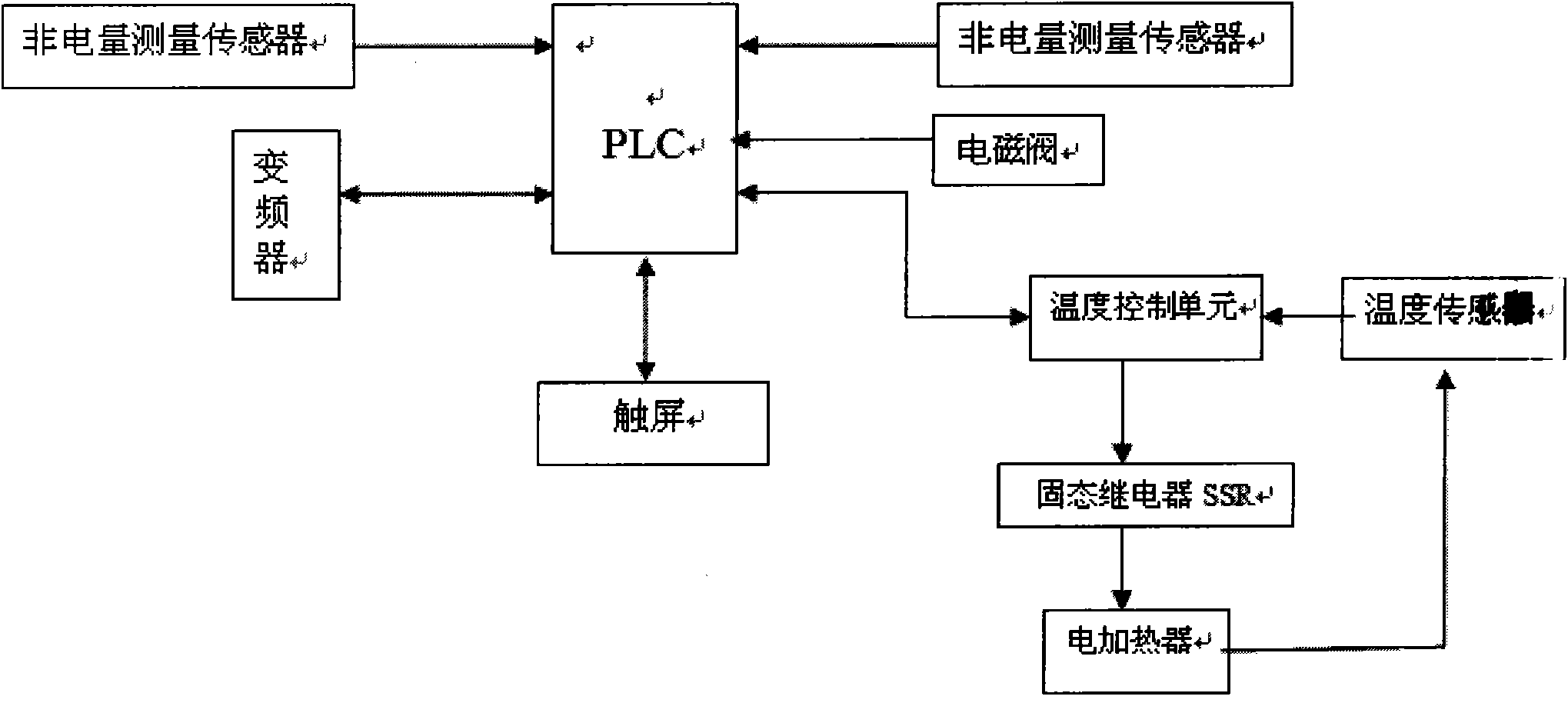

[0034] The transmission system of the mechanical part, the transmission system, the water gas system and the temperature system constitute a complete oral liquid glass bottle washing, drying, filling and rolling linkage unit, in which the bottle knocking and turning plate structures are in the transmission system.

[0035] The oral liquid glass bottle washing, drying, filling and rolling unit control system automatically completes the drive and control of the four major systems after the operator sends out the start command. At the same time, the field bus electronic control system monitors the failure of each component and link of the equipment in real time and starts immediately Protection, and real-time display of working conditions.

[0036] (1) Setting of driving and temperature heating elements

[0037] 1. Setting of driving components of the fieldbus electronic control system

[0038] ① 8 motors

[0039] The driving objects are the washing transmission system, the washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com