Production process of nuclear bolt

A production process and bolt technology, which is applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems that the requirements for strength, hardness and impact resistance are very strict, and the production process cannot meet the requirements, so as to achieve strong anti-corrosion ability, Good lubricity and fine phosphating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The production process of nuclear power bolts, the technological process is blank preparation-heat treatment-flaw detection inspection-surface treatment.

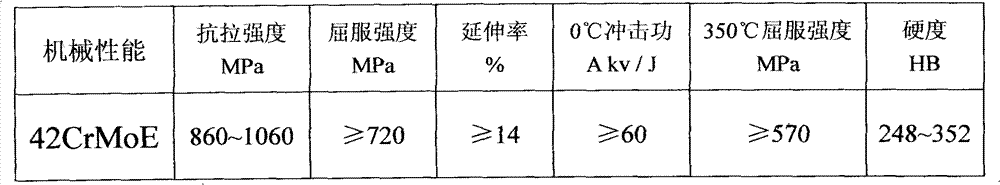

[0034] Using 42CrMoE steel as raw material, the chemical composition mass percentage is: C content 0.405%, Si content 0.23%, Mn content 0.78%, P content 0.012%, S content 0.013%, Cr content 0.94%, Mo content 0.17%, the balance is Fe. Raw material production inspection, blanking, plane chamfering, heat treatment, thread blank diameter grinding, thread rolling.

[0035] The heat treatment process quenches and tempers bolts < 0.5M and bolts ≥ 0.5M respectively. Bolts with a length of less than 0.5M are quenched in a mesh belt furnace with alloy steel quenching oil as the medium, the quenching temperature is 850°C, and the holding time is 2 hours. After quenching, continue tempering in the mesh belt furnace, the tempering temperature is 680°C, and the holding time is 2.5 hours.

[0036] Bolts with a length ≥ 0.5M are ...

Embodiment 2

[0039] The raw materials and process flow of this embodiment are the same as those in Embodiment 1, except that in the heat treatment process, for bolts with a length <0.5M, the quenching temperature is 860° C., and the holding time is 2 hours. After quenching, continue tempering in the mesh belt furnace, the tempering temperature is 630°C, and the holding time is 2.5 hours.

[0040] Bolts with a length ≥ 0.5M are quenched in a pit furnace with mechanical oil as the medium, the quenching temperature is 860°C, and the holding time is 2.5 hours. After quenching, continue to temper in the pit furnace, the tempering temperature is 630°C, and the time is 3 hours.

Embodiment 3

[0042] The process flow of this embodiment is the same as that of Embodiment 1, the difference is the raw materials and heat treatment process.

[0043] Using 42CrMoE steel as raw material, the chemical composition mass percentage is: C content 0.38%, Si content 0.10%, Mn content 0.75%, P content 0.025%, S content 0.015%, Cr content 0.80%, Mo content 0.15%, the balance is Fe.

[0044] For bolts with a length less than 0.5M, the quenching temperature is 860°C and the holding time is 2 hours. After quenching, continue tempering in the mesh belt furnace, the tempering temperature is 620°C, and the holding time is 2.5 hours.

[0045] Bolts with a length ≥ 0.5M are quenched in a pit furnace with mechanical oil as the medium, the quenching temperature is 860°C, and the holding time is 2.5 hours. After quenching, continue to temper in the pit furnace, the tempering temperature is 620°C, and the time is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com