Preparation method of mesoporous hollow sphere-shaped tungsten carbide

A hollow spherical, tungsten carbide technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve problems such as difficult structural transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

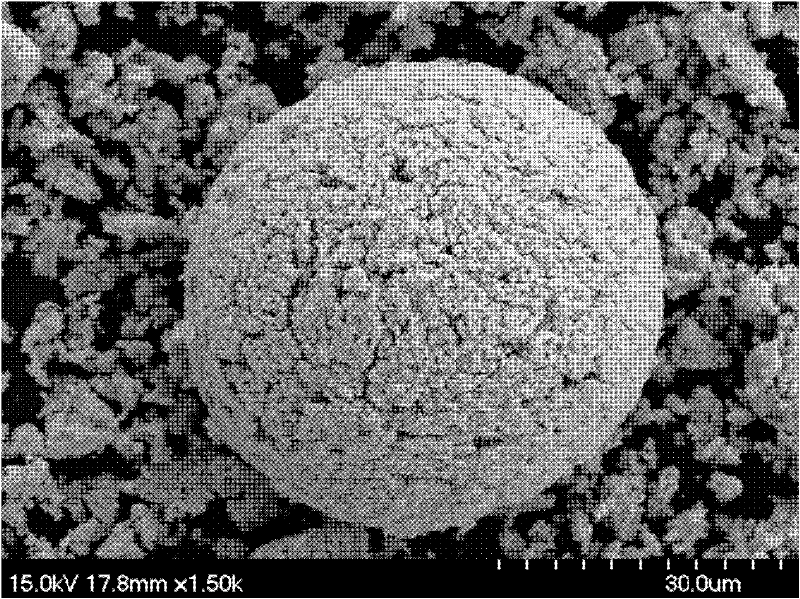

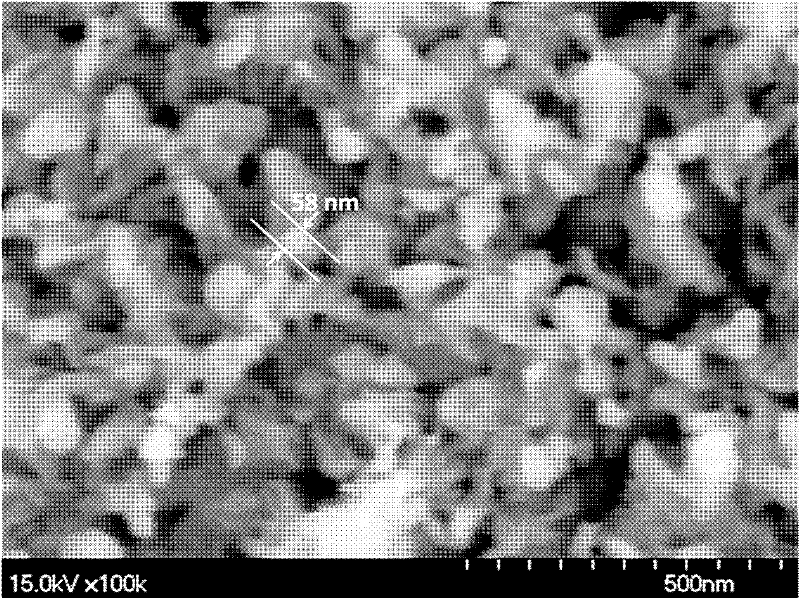

Embodiment 1

[0026] At room temperature, add 5g of ammonium metatungstate to 10ml of deionized water, and disperse by ultrasonication for 5 minutes. Take 250ml of absolute ethanol and pour it into a glass container, then put the glass container filled with absolute ethanol into the ultrasonic wave, and fix it after the ethanol liquid level in the glass container is higher than the ultrasonic medium liquid level. Add the ammonium metatungstate solution dropwise to absolute ethanol at a rate of 3 s at a rate of 5 μl / drop; when the ammonium metatungstate droplet is dropped into ethanol, precipitation occurs after instant granulation, and continues to be dispersed by ultrasound. After filtration, carry out vacuum drying at 40°C to obtain white solid ammonium metatungstate particles, in the volume ratio of 1:1.1 CO / H 2 The obtained ammonium metatungstate crystals were carbonized under atmosphere. According to the 2°C / min program, the temperature was raised to 750°C and kept for 8 hours. Obtai...

Embodiment 2

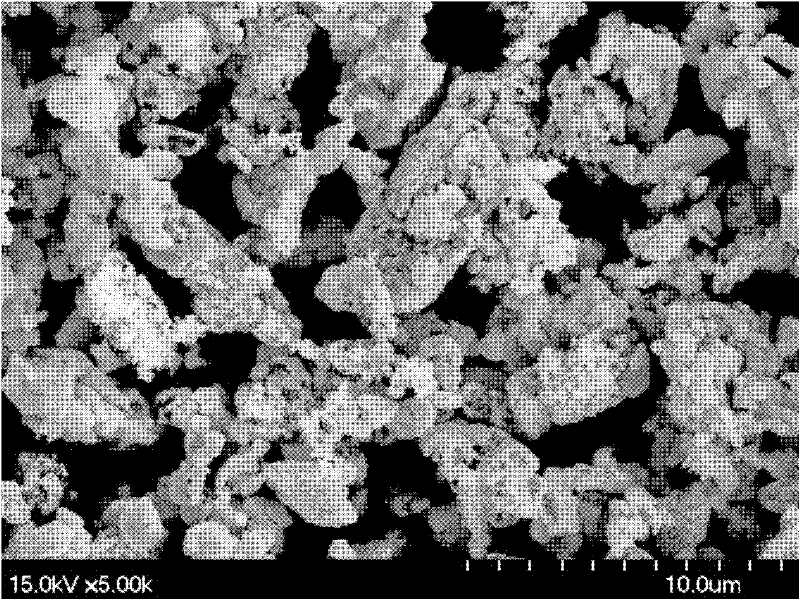

[0028] At room temperature, add 15g of ammonium metatungstate to 10ml of deionized water, and disperse by ultrasonication for 20 minutes. Take 200ml of absolute ethanol and pour it into a glass container, then put the glass container filled with absolute ethanol into the ultrasonic wave, and fix it after the ethanol liquid level in the glass container is higher than the ultrasonic medium liquid level. Add the ammonium metatungstate solution dropwise to absolute ethanol at 2 μl / drop, with an interval of 4 seconds between each drop; when the ammonium metatungstate droplet is dropped into ethanol, precipitation occurs after instant granulation, and continues to be dispersed by ultrasonication. After filtration, carry out vacuum drying at 45°C to obtain white solid ammonium metatungstate particles, in the volume ratio of 1:1.8 CO / H 2 The obtained ammonium metatungstate crystals were carbonized under atmosphere. According to the 3°C / min program, the temperature was raised to 750°C...

Embodiment 3

[0030] At room temperature, add 20g of ammonium metatungstate to 10ml of deionized water, and disperse by ultrasonication for 30 minutes. Take 250ml of absolute ethanol and pour it into a glass container, then put the glass container filled with absolute ethanol into the ultrasonic wave, and fix it after the ethanol liquid level in the glass container is higher than the ultrasonic medium liquid level. Add the ammonium metatungstate solution dropwise to absolute ethanol at 1 μl / drop, with an interval of 2 seconds between each drop; when the ammonium metatungstate droplet is dropped into ethanol, precipitation occurs after instant granulation, and continues to be dispersed by ultrasonication. After filtration, carry out vacuum drying at 60°C to obtain white solid ammonium metatungstate particles, in the volume ratio of 1:2.5 CO / H 2 The obtained ammonium metatungstate crystals were carbonized under atmosphere. According to the 10°C / min program, the temperature was raised to 900°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com