Negative plate of lead acid super battery, production method and lead acid super battery assembled by negative plate

A super battery and negative plate technology, which is applied in the direction of lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., can solve the problems of short working life of lead-acid super batteries, and achieve the purpose of suppressing hydrogen evolution on the surface, improving the state of charge, and good electrical conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

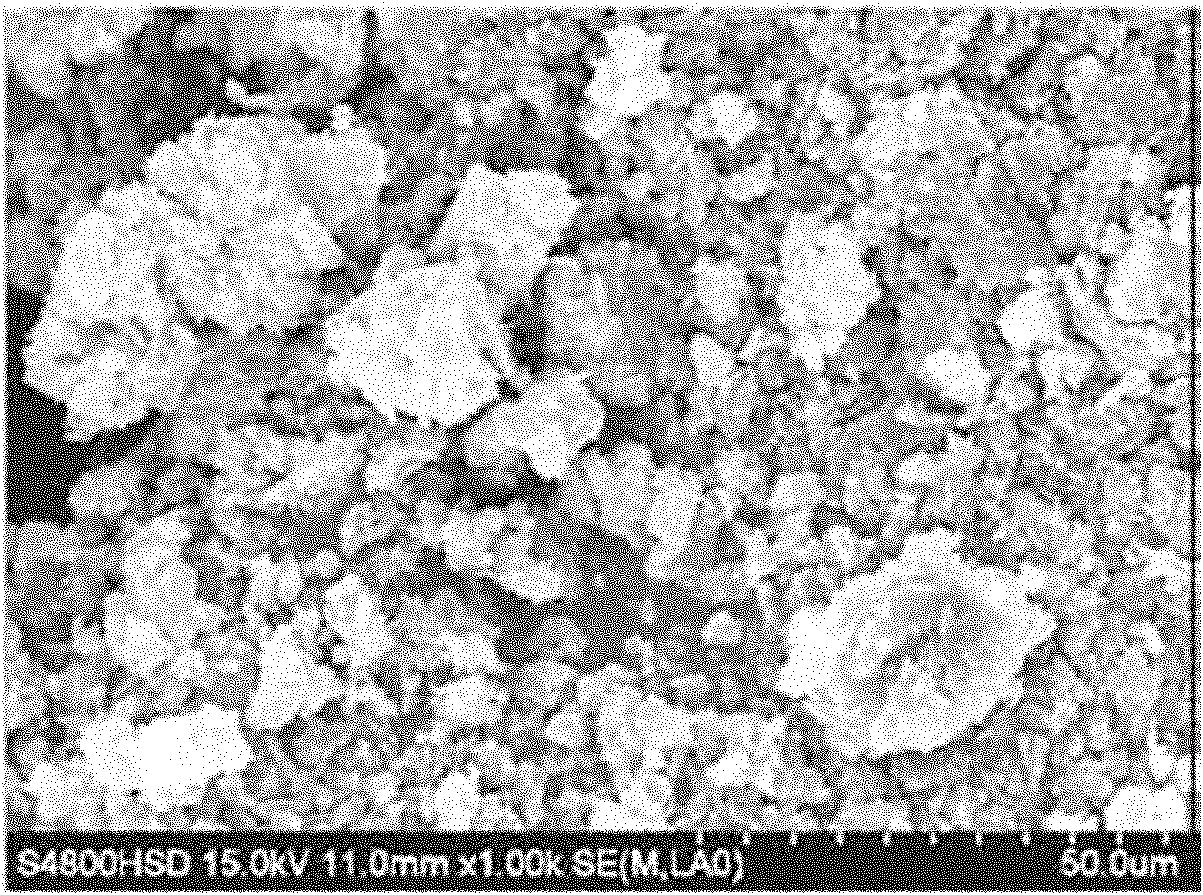

[0019] Embodiment 1: This embodiment is a lead-acid super battery negative plate, including a negative electrode grid and a negative electrode paste coated on the negative electrode grid, wherein the outer surface of the negative electrode paste is covered with a capacitor carbon paste layer, and the negative electrode paste is coated with a capacitor carbon paste layer. Expanded mesophase carbon microspheres (MCMB) are added, wherein, the capacitor carbon paste layer consists of 70-80 parts by weight of activated carbon loaded with lead oxide, 5-10 parts of polytetrafluoroethylene, 0.1-1 part It consists of sodium carboxymethyl cellulose, 0.1-2 parts of stearic acid and 5-20 parts of acetylene black, and the expanded mesophase carbon microspheres account for 0.1%-5% of the mass of the lead powder in the negative electrode paste.

[0020] In this embodiment, the high-performance supercapacitor material expansion mesophase carbon microspheres suitable for sulfuric acid electroly...

specific Embodiment approach 2

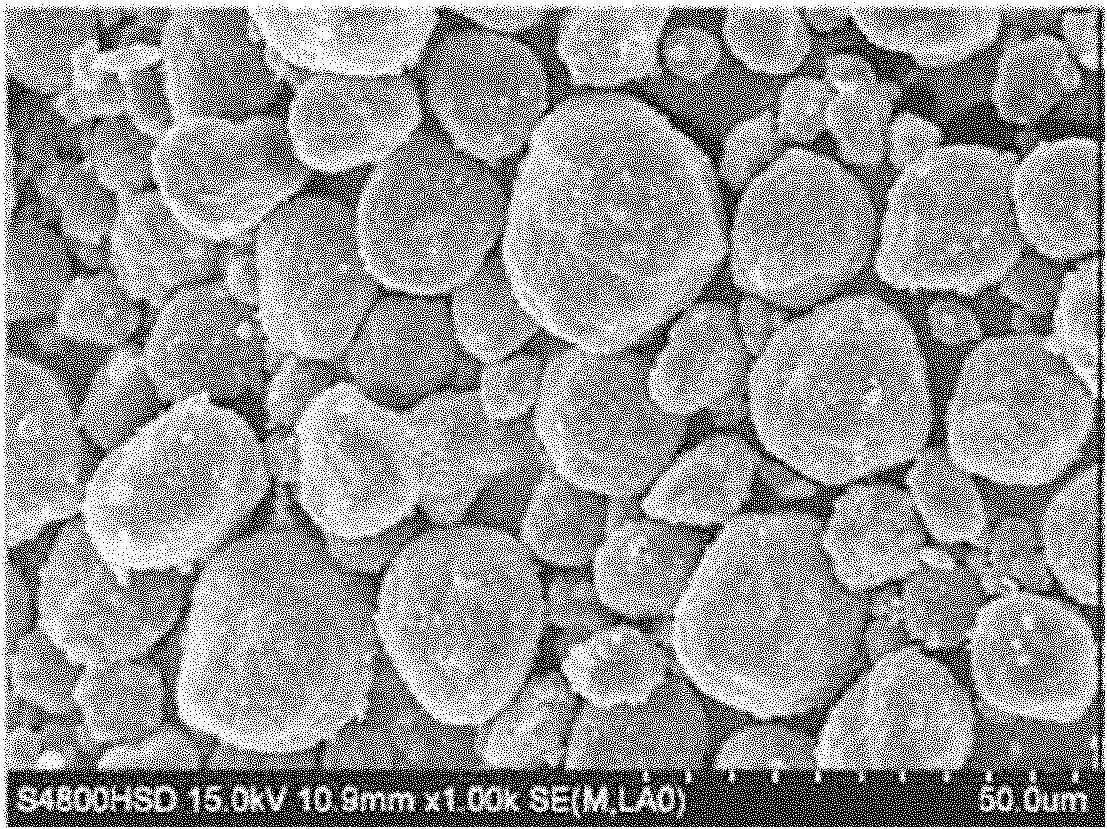

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that activated carbon, sub-nanometer graphite and conductive carbon black of loaded lead oxide (PbO) are also added in the negative electrode lead paste, wherein the mass of lead powder in the negative electrode lead paste As the base, the activated carbon loaded with lead oxide accounts for 0.1% to 10% of the base, the subnano graphite accounts for 0.1% to 3% of the base, and the conductive carbon black accounts for 0.1% to 5% of the base. Other parameters are the same as in the first embodiment.

[0024] In this embodiment, the high-performance supercapacitor material expanded mesophase carbon microspheres suitable for sulfuric acid electrolyte are mixed into the negative electrode paste of the lead-acid super battery, as well as activated carbon loaded with lead oxide, sub-nanometer graphite and conductive carbon black, At the same time, the supercapacitor material is effecti...

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the preparation method of the expanded mesophase carbon microspheres is as follows: 1. Place the container in an ice bath, then add concentrated sulfuric acid to the container, and then Add mesophase carbon microspheres and sodium nitrate into concentrated sulfuric acid, stir for 15-30 minutes, then add potassium permanganate, stir for 10 minutes, then place the container at 30-40°C for 1-5 hours to obtain viscous Thick liquid, wherein the ratio of the volume of concentrated sulfuric acid to the mass of mesophase carbon microspheres is 20-40mL: 1g, the mass ratio of sodium nitrate to mesophase carbon microspheres is 0.3-0.6:1, potassium permanganate and mesophase carbon microspheres are The mass ratio of the balls is 1.5-4:1; 2. Add the viscous liquid in step 2 into distilled water, stir at room temperature for 1-2 hours, then add hydrogen peroxide, stir at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com