Ag-CuO-NrGO air electrode with supercapacitor performance and preparation method

An air electrode and supercapacitor technology, applied to battery electrodes, fuel cell half-cells, primary battery half-cells, electrical components, etc., can solve the problems of easy falling off of the catalyst layer and low efficiency of zinc-air batteries, and achieve Effect of improving charge-discharge cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

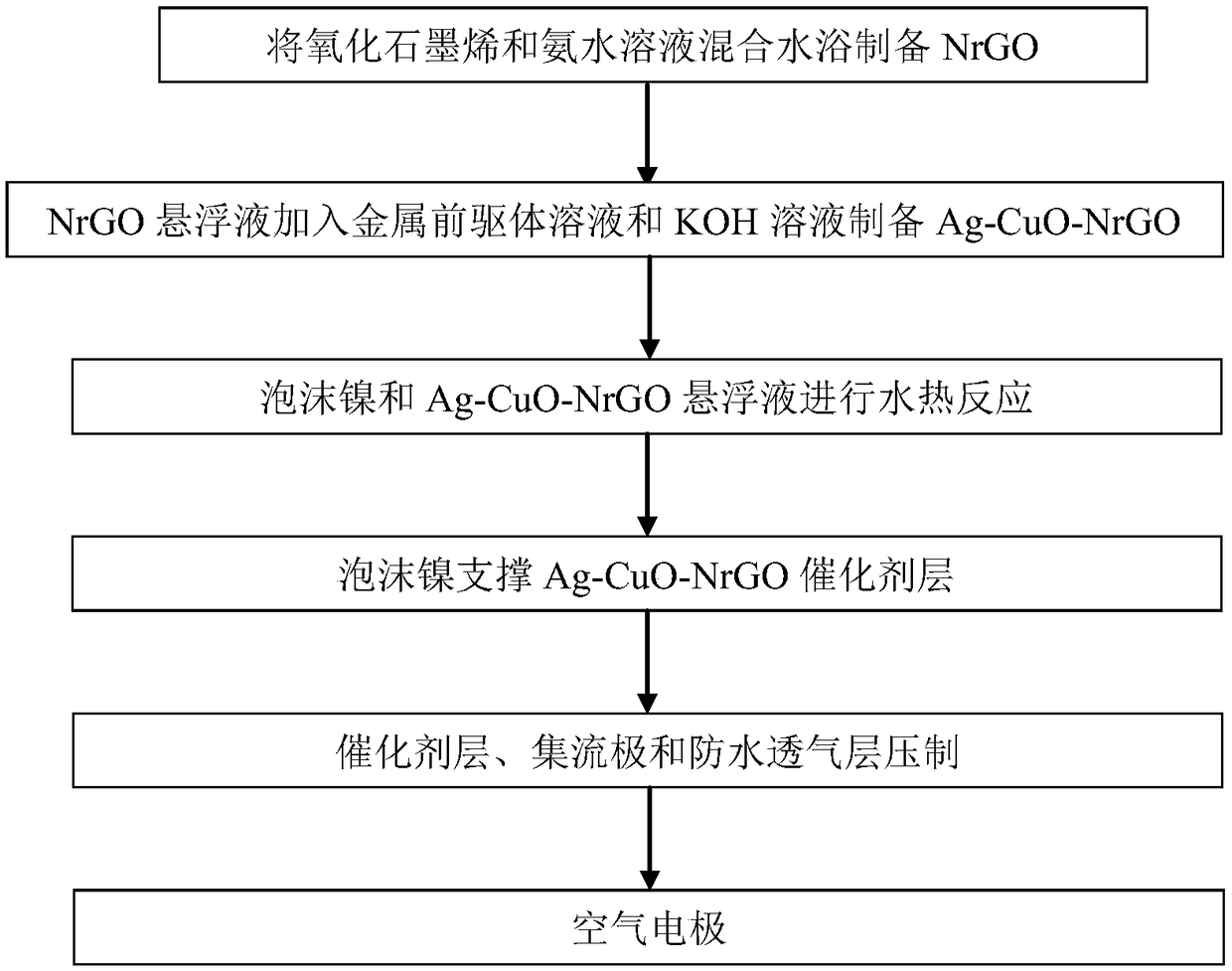

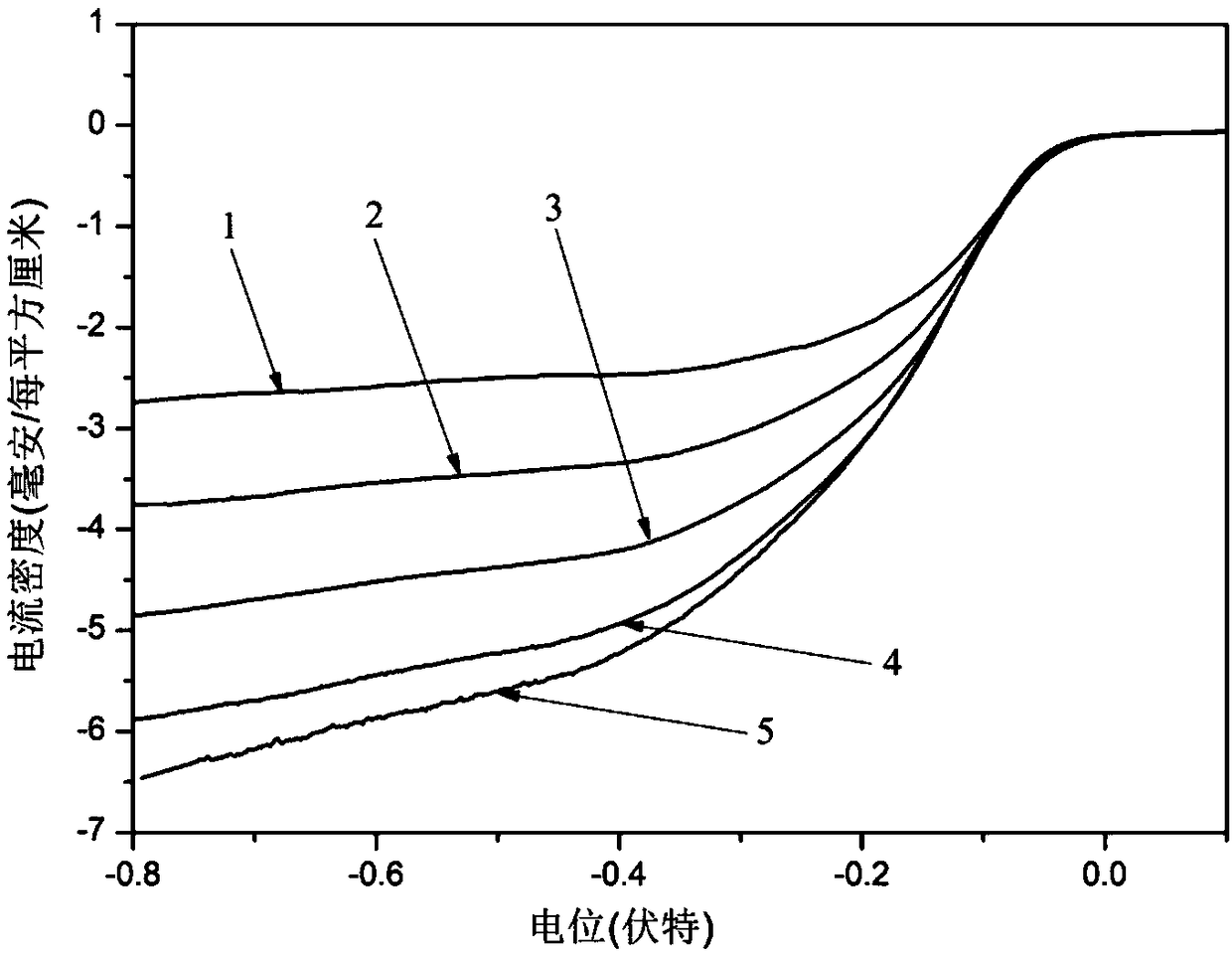

Embodiment 1

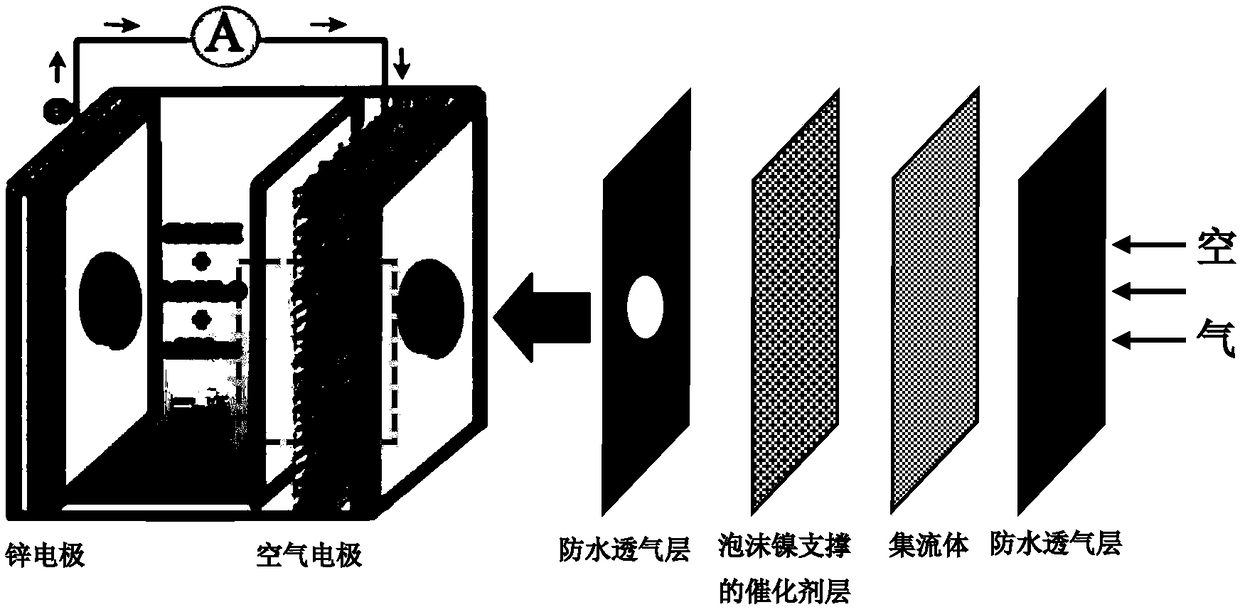

[0034] This example is a CuO-NrGO catalyst layer supported by nickel foam, wherein the ratio of CuO and NrGO is 16:84. Mix 13 mL of graphene oxide and 27 mL of deionized water and stir for 1 hour, put in an oil bath and stir for 10 minutes, then add 5 mL of NH 3 ·H 2 O, stir and keep the temperature at 80°C for 24 hours. Centrifuge and wash multiple times with deionized water to remove remaining NH 3 ·H 2 O, the resulting product is nitrogen-doped reduced graphene oxide NrGO (the NrGO catalyst can be obtained by freeze-drying it). Afterwards, it was dispersed in deionized water and ultrasonicated for 30 minutes to obtain a uniformly dispersed suspension. 1.6 mL of 0.1M CuCl 2 The aqueous solution was added dropwise to the NrGO suspension and stirred for 10 minutes, then 6 mL of 0.1 M KOH was added dropwise and stirred for 1 hour. The suspension was centrifuged and washed with deionized water several times, followed by freeze-drying to obtain the CuO-NrGO catalyst. Put t...

Embodiment 2

[0036] This example is an air electrode prepared by foaming nickel to support an Ag-CuO-NrGO catalyst layer, wherein the ratio of Ag-CuO to NrGO is 9:91. Mix 13 mL of graphene oxide and 27 mL of deionized water and stir for 1 hour, put in an oil bath and stir for 10 minutes, then add 5 mL of NH 3 ·H 2 O, stir and keep the temperature at 80°C for 24 hours. Centrifuge and wash multiple times with deionized water to remove remaining NH 3 ·H 2 O, the resulting product is nitrogen-doped reduced graphene oxide NrGO (the NrGO catalyst can be obtained by freeze-drying it). Afterwards, it was dispersed in deionized water and ultrasonicated for 30 minutes to obtain a uniformly dispersed suspension. 1.6mL of 0.05M AgNO 3 -Cu(NO 3 ) 2 The aqueous solution was added dropwise to the NrGO suspension and stirred for 10 minutes, then 6 mL of 0.1 M KOH was added dropwise and stirred for 1 hour. The Ag-CuO-NrGO catalyst was obtained by centrifuging the suspension and washing it several t...

Embodiment 3

[0040] This example is an air electrode prepared by foaming nickel to support an Ag-CuO-NrGO catalyst layer, wherein the ratio of Ag-CuO to NrGO is 16:84. Mix 13 mL of graphene oxide and 27 mL of deionized water and stir for 1 hour, put in an oil bath and stir for 10 minutes, then add 5 mL of NH 3 ·H 2 O, stir and keep the temperature at 80°C for 24 hours. Centrifuge and wash multiple times with deionized water to remove remaining NH 3 ·H 2 O, the resulting product is nitrogen-doped reduced graphene oxide NrGO (the NrGO catalyst can be obtained by freeze-drying it). Afterwards, it was dispersed in deionized water and ultrasonicated for 30 minutes to obtain a uniformly dispersed suspension. 1.6mL of 0.1M AgNO 3 -Cu(NO 3 ) 2 The aqueous solution was added dropwise to the NrGO suspension and stirred for 10 minutes, then 6 mL of 0.1 M KOH was added dropwise and stirred for 1 hour. The Ag-CuO-NrGO catalyst was obtained by centrifuging the suspension and washing it several t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com