Method for preparing water-oil repellent fluorine-containing textile finishing agent

A fluorine-containing fabric, water-repellent and oil-repellent technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of high cost, harsh operation, unfavorable development, etc., and achieve low cost, good mechanical stability, good water and repellency The effect of oil properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

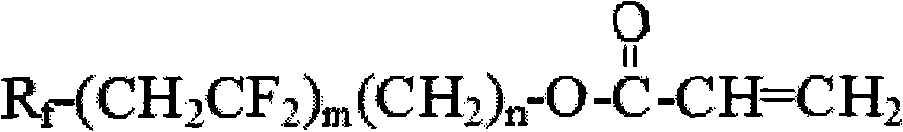

[0059] 100g perfluorononenyloxyethyl acrylate, 80g hexadecyl acrylate, 20g N-methylolacrylamide, 5g polyoxyethylene laurate (9), 5g octadecyltrimethylammonium chloride, 40g Acetone and 0.6g of dodecyl mercaptan were added to a 1000ml four-neck flask, heated at 30°C to melt, and 400ml of water was continuously added dropwise under high shear conditions for pre-emulsification, and 1g of potassium persulfate was added to the pre-emulsion after ultrasound , Polymerized at 50°C for 0.5h. Water repellency 70 points, oil repellency 2 grades.

Embodiment 2

[0061] 90g perfluorononenyloxyethyl methacrylate, 100g octadecyl methacrylate, 10g N-methylolacrylamide, 15g polyoxyethylene laurate (9), 15g hexadecyl trimethyl bromide Ammonium chloride, 100g of isopropanol, and 1.4g of dodecyl mercaptan were added to a 1000ml four-neck flask, heated at 60°C to melt, and 600ml of water was continuously added dropwise under high shear conditions for pre-emulsification. The pre-emulsion was ultrasonically Afterwards, 1.5 g of benzoyl peroxide was added, and polymerized at 70° C. for 1 h. 80 points for water repellency and 3 grades for oil repellency.

Embodiment 3

[0063] 80g perfluorononenylamine ethyl methacrylate, 100g hexadecyl acrylate, 20g gamma-mercaptopropyltrimethoxysilane, 10g polyoxyethylene laurate (9), 20g dodecyl trimethyl bromide Add ammonium chloride, 30g acetone, 30g isopropanol, and 1.4g dodecyl mercaptan into a 1000ml four-neck flask, heat it at 80°C to melt it, and add 800ml water continuously under high shear conditions for pre-emulsification. After ultrasonication, 1.6 g of azobisisobutylamidine dihydrochloride was added to the emulsion, and polymerized at 60° C. for 5 hours. 80 points for water repellency and 2 grades for oil repellency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com