Process for preparing olefins by methanol dehydration

A technology for methanol dehydration and olefin production, which is applied in the chemical industry, can solve the problems of easy carbonization and deactivation of catalysts, low olefin yield, and high olefin yield, so as to ensure high activity and long-term stable reaction, improve olefin yield, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

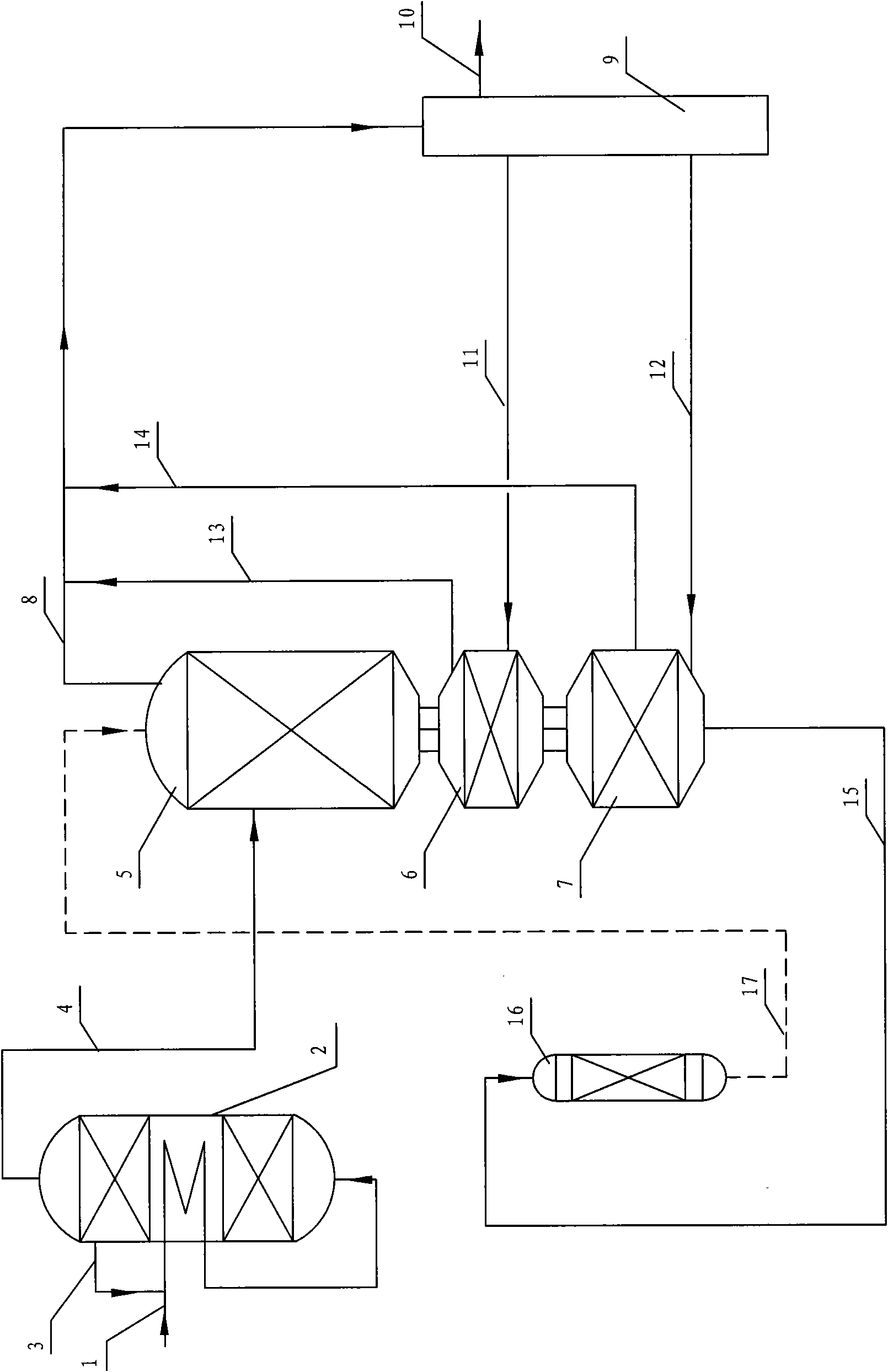

[0024] As shown in the figure, the raw material methanol 1 passes through the catalyst bed of catalytic distillation reactor 2 and heats it into steam, then enters the lower part of catalytic distillation reactor 2, and reacts with the shape-selective ZSM-5 zeolite molecular sieve catalyst. The reaction temperature is 200~280℃, preferably 210-250℃, and the weight hourly space velocity is 1~6h -1 , preferably 3~5h -1 . In the catalytic distillation reactor 2, the unreacted methanol stream 3 and the water generated by the reaction are respectively extracted from the side line of the catalytic distillation reactor 2. After the unreacted methanol stream 3 is mixed with the raw material methanol 1, it enters the catalytic distillation reactor 2 for reaction, and the reaction product The dimethyl ether stream 4 enters the first moving bed reactor 5 after coming out from the top of the catalytic distillation reactor 2, and contacts with the catalyst for catalytic reaction; the gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com