Reaction system and method for preparing lactide from oligomer

A reaction system, lactide technology, applied in separation methods, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, etc. In order to improve the reaction separation efficiency, achieve full recycling and simple structure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

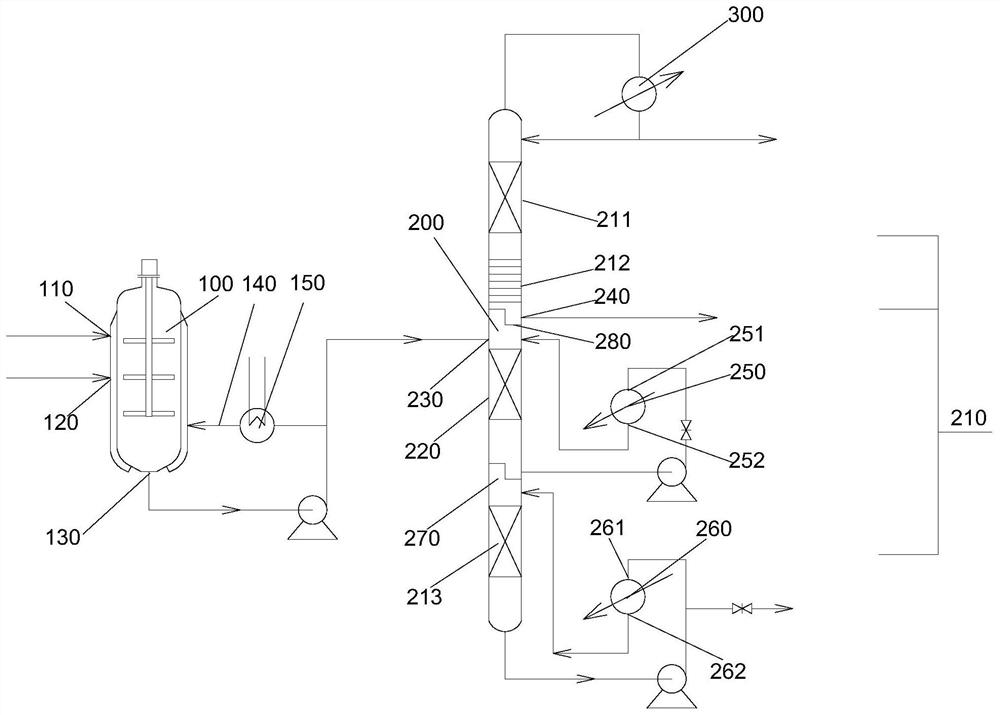

[0075] refer to figure 1 As shown, it is a reaction system for preparing lactide from an oligomer in an embodiment of the present invention, which includes a lactide synthesis kettle 100 and a reactive distillation tower 200 connected in sequence. The reactive distillation tower 200 includes a rectification Distillation section 210 and lactide deep synthesis section 220.

[0076] The rectification section 210 includes a light component separation section 211 for separating water, lactic acid and a small amount of oligomers, a product separation section 212 for lactide product separation, and a heavy component separation section 213 for separating oligomers, The light component separation section 211 and the product separation section 212 are arranged on the upper part of the lactide deep synthesis section 220 from top to bottom, and the heavy component separation section 213 is arranged on the lower part of the lactide deep synthesis section 220; A first feed port 230 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com