Lactic acid oligomer synthesis system capable of regulating and controlling polymerization degree and synthesis method thereof

A technology of lactic acid oligomer and synthesis method, applied in the field of biodegradable material production, can solve problems such as wide distribution of polymerization degree of lactic acid oligomer, and achieve the effect of solving wide distribution of polymerization degree, concentrated degree of polymerization, and optimizing reaction route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

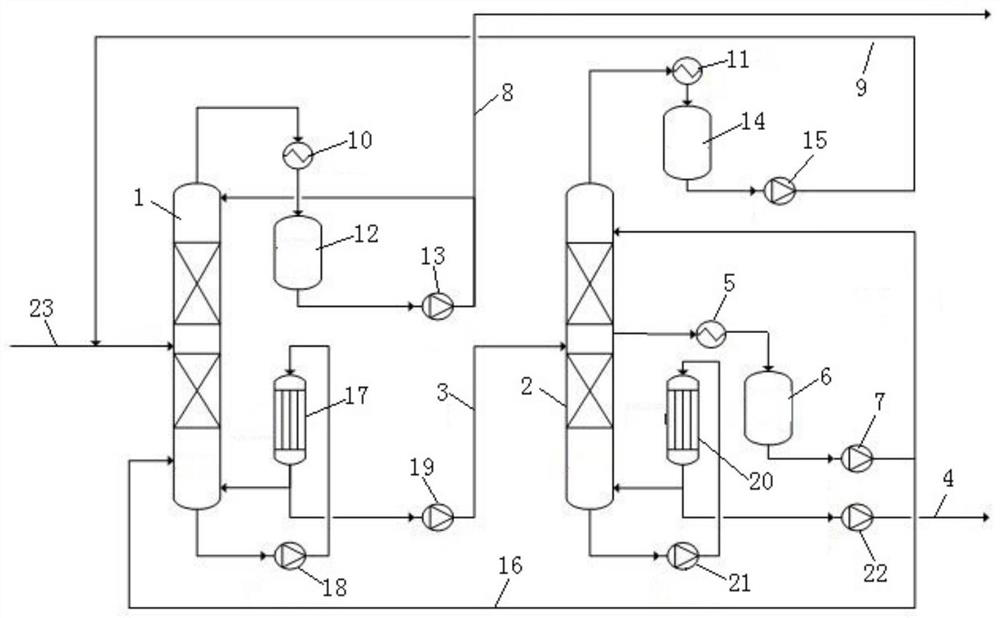

[0050] The present invention also includes a method for synthesizing lactic acid oligomers that can regulate the degree of polymerization, which includes the following steps:

[0051] S1. Send the raw material lactic acid into the first reaction rectification tower 1 for polycondensation reaction and rectification separation. The working pressure is 5-30KPaA, the reaction temperature is 100-170°C, and the residence time is 1-4h to obtain the first light group and the first heavy component, the first light component is discharged into the first condensation system, and the first heavy component is sent into the second reactive distillation column 2 through the first tower still extraction pipe 3;

[0052] S2. The second reactive distillation tower 2 performs polycondensation reaction and rectification separation on the first heavy component, the working pressure is 0.1-5.0KPaA, the reaction temperature is 160-190°C, and the residence time is 1-4h to obtain the second light compo...

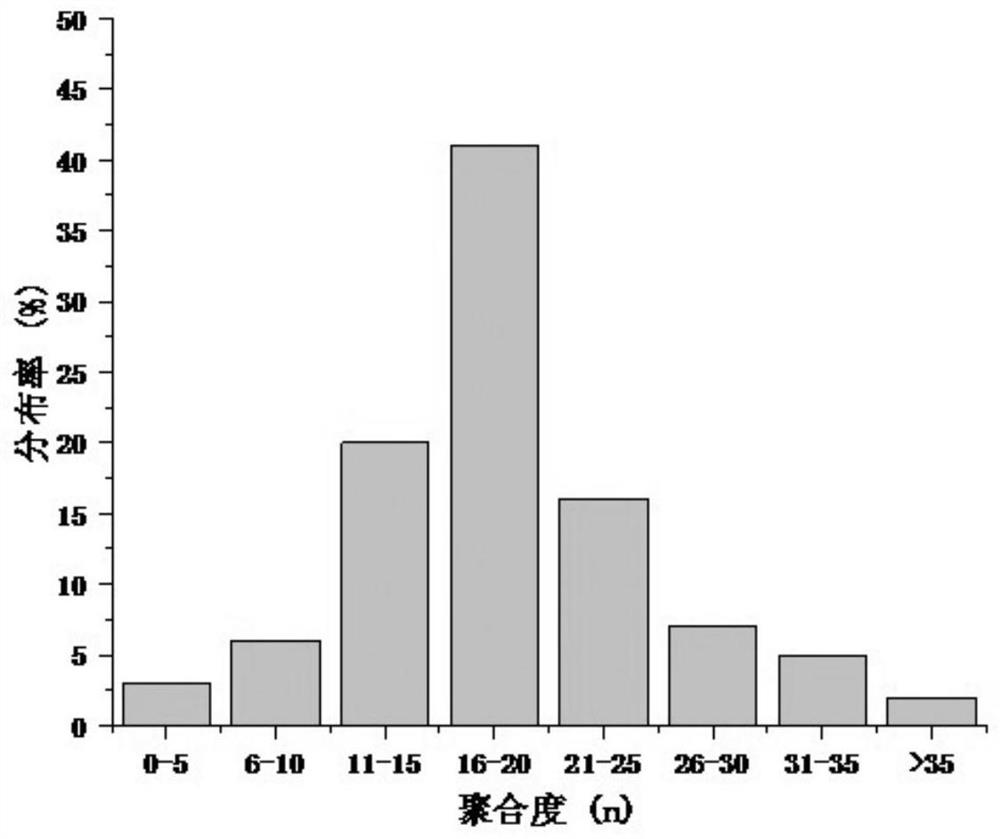

Embodiment 2

[0063] The synthesis method and system used in this example are the same as in Example 1, except that the operating temperature of the materials in the first reactive distillation column is 155°C, and the operating temperature of the second reactive distillation column is 180°C.

[0064] The degree of polymerization distribution rate of the target product obtained in this example is as follows: the degree of polymerization accounts for 9% in the interval of 0-5, the proportion of degree of polymerization in the interval of 6-10 accounts for 18%, and the degree of polymerization in the interval of 11-15 The proportion is 24%, the proportion of the degree of polymerization in the range of 16-20 is 29%, the proportion of the degree of polymerization in the range of 21-25 is 10%, the proportion of the degree of polymerization in the range of 26-30 is 6%, the proportion of the degree of polymerization is In the range of 31-35, the proportion is 3%, and in the range of the degree of ...

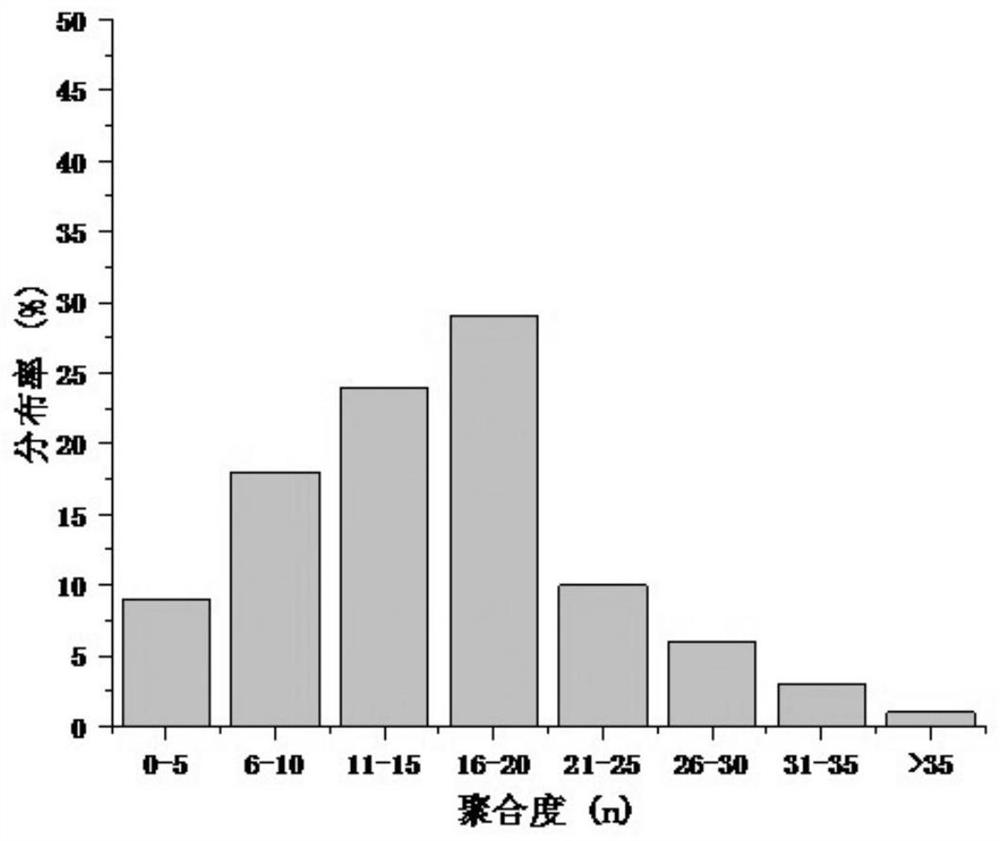

Embodiment 3

[0066] The synthesis method and system used in this example are the same as in Example 1, except that the operating temperature of the materials in the first reactive distillation column is 165°C, and the operating temperature of the second reactive distillation column is 190°C.

[0067] The degree of polymerization distribution rate of the target product obtained in this example is as follows: the degree of polymerization accounts for 2% in the interval of 0-5, the proportion of degree of polymerization in the interval of 6-10 is 3%, and the degree of polymerization in the interval of 11-15 The proportion is 13%, the proportion of the degree of polymerization in the range of 16-20 is 26%, the proportion of the degree of polymerization in the range of 21-25 is 28%, the proportion of the degree of polymerization in the range of 26-30 is 17%, the proportion of the degree of polymerization is 7% in the range of 31-35, and 4% in the range of aggregation degree greater than 35. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com