Process for cutting silicon wafer by using steel wire with diameter of 0.1mm

A steel wire and silicon wafer technology, which is applied in the process of cutting silicon wafers with a steel wire with a diameter of 0.1mm, can solve the problems of increased wire breakage rate and reduced cutting ability, and achieves reduction of cutting loss, obvious benefits, and reduced cutting loss. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

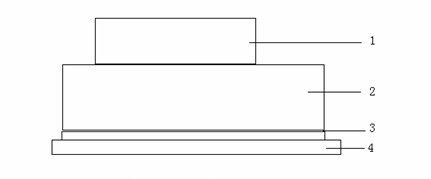

Image

Examples

Embodiment Construction

[0017] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with embodiment:

[0018] The steel wire used in this example is a steel wire with a diameter of 0.10mm. The corundum is 2000# green silicon carbide, the cutting fluid is PEG205, the groove distance of the groove wheel used is 350μm, the multi-wire cutting machine model: Meyerberg DS-264; raw material: 125*125 solar square rod, the following is the used diameter 0.11 The production method and specific process of mm steel wire cutting silicon wafers:

[0019] (1) Mortar configuration: The operator will dry the corundum, the drying temperature is 40-70 degrees, and the drying time is 20-60 minutes. This example uses 40 minutes. Calculate the amount of cutting fluid and emery according to the ratio (in this example, the mass ratio of cutting fluid: emery = 1:0.95), weigh them, and prepare the mortar in the mixing bucket. The mixing time is 6-24 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com