Diffusion welding method of tungsten alloy and tantalum alloy at low temperature

A diffusion welding and tungsten alloy technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of reducing material fracture toughness, low corrosion resistance, reducing material service life, etc., to achieve strong applicability, flat surface Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

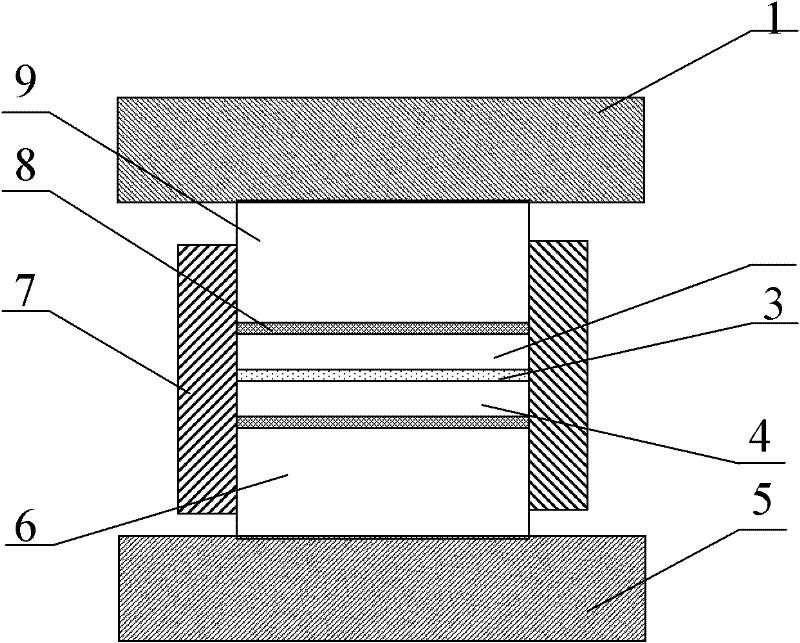

Method used

Image

Examples

Embodiment 1

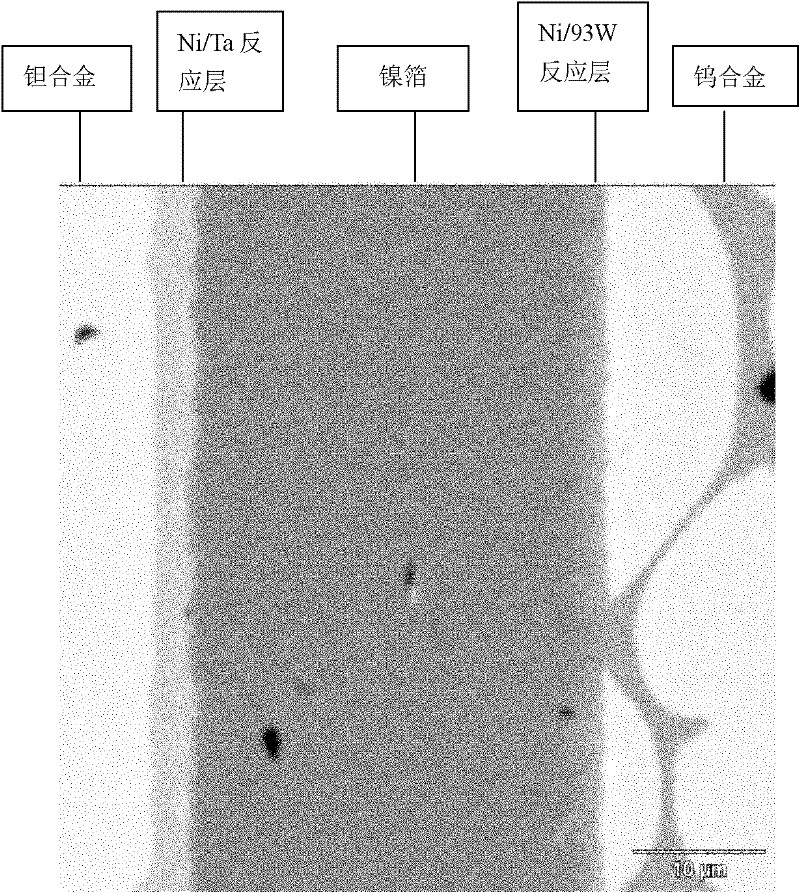

[0032] A nickel foil with a thickness of 38 μm is selected as the intermediate layer for welding 93W-4.9Ni-2.1Fe alloy and TA1 industrial pure tantalum disc. The diffusion welding process conditions are: welding temperature 930 ° C, holding time 10 min, welding pressure 30 MPa.

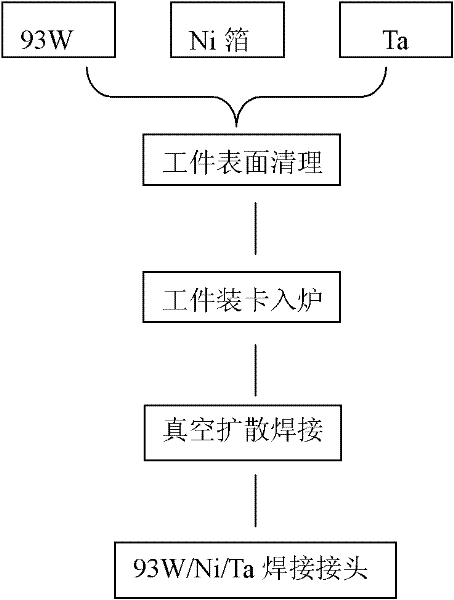

[0033] A method for low-temperature diffusion welding of tungsten alloys and tantalum alloys using a nickel intermediate layer, comprising the following steps:

[0034] (1) Surface cleaning of the workpiece:

[0035] The weldment is 93W-4.9Ni-2.1Fe alloy with a diameter of 23mm and industrial pure tantalum disc; the middle layer of 38μm nickel foil is 99.0% pure and 23mm in diameter. The surface was ultrasonically cleaned with acetone solution for 10 min. Use a surface grinder to process tungsten alloy sheets and tantalum alloy sheets into round sheets with a parallelism better than 0.05mm. Before welding, use 1000#, 1200# and No. 05, 06 metallographic sandpaper to polish the surface to be welded of ...

Embodiment 2

[0042] The 38μm nickel foil is selected as the intermediate layer connecting the 93W-4.9Ni-2.1Fe alloy and the TA2 industrial pure tantalum disc. The diffusion welding process conditions are: welding temperature 810 ℃, holding time 90min, welding pressure 5MPa.

[0043] A method for low-temperature diffusion welding of tungsten alloys and tantalum alloys using a nickel intermediate layer, comprising the following steps:

[0044] (1) Surface cleaning of the workpiece:

[0045] The weldment is a 93W-4.9Ni-2.1Fe alloy with a diameter of 50mm and an industrially pure tantalum disc. The 38μm nickel intermediate layer is 99.0% pure and 50mm in diameter. Before welding, use No. 05 and No. 06 metallographic sandpaper to polish the surface to be welded of the disc. , ultrasonic cleaning with acetone solution for 1 min. Use a surface grinder to process tungsten alloy sheets and tantalum alloy sheets into round sheets with a parallelism better than 0.05mm. Before welding, use 1000#, 120...

Embodiment 3

[0052] A 5 μm nickel foil was selected as the intermediate layer connecting the 93W-4.9Ni-2.1Fe alloy and the TA1 industrial pure tantalum wafer. The diffusion bonding process conditions were: welding temperature 930°C, holding time 10min, and welding pressure 5MPa.

[0053] A method for low-temperature diffusion welding of tungsten alloys and tantalum alloys using a nickel intermediate layer, comprising the following steps:

[0054] (1) Surface cleaning of the workpiece:

[0055] The weldment is a 93W-4.9Ni-2.1Fe alloy with a diameter of 50mm and an industrial pure tantalum disc. The nickel intermediate layer is 99.0% pure and 50mm in diameter. Ultrasonic cleaning with acetone solution for 1 min. Use a surface grinder to process tungsten alloy sheets and tantalum alloy sheets into round sheets with a parallelism better than 0.05mm. Before welding, use 1000#, 1200# and No. 05, 06 metallographic sandpaper to polish the surface to be welded of the round sheets, and use acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com