Ceramide-containing tea seed extract and preparation method thereof

The technology of ceramide and extract is applied to the field of tea seed extract containing ceramide and its preparation, which can solve the problems of high cost and complicated process, and achieve the effects of low production cost, simple preparation process and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

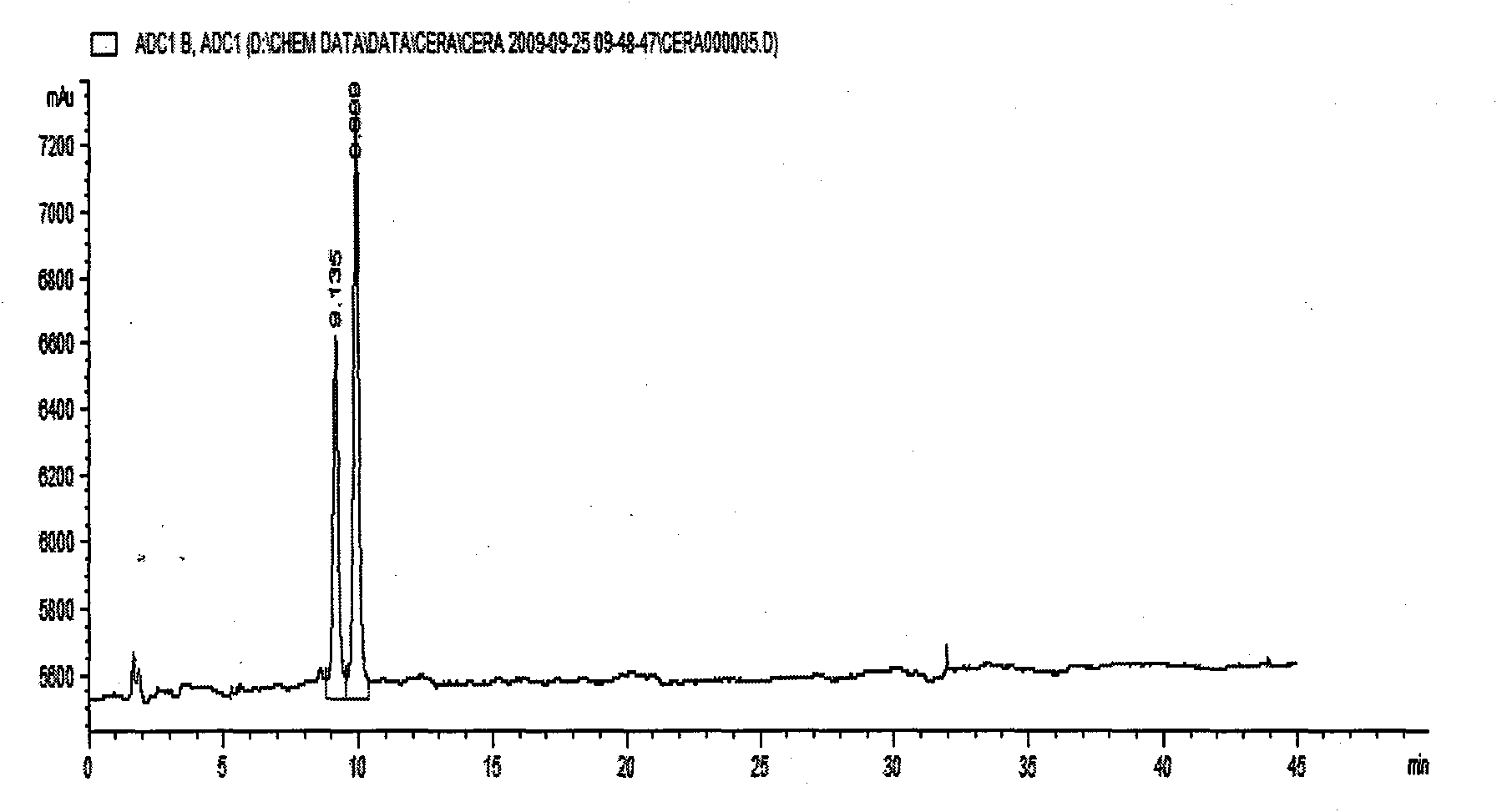

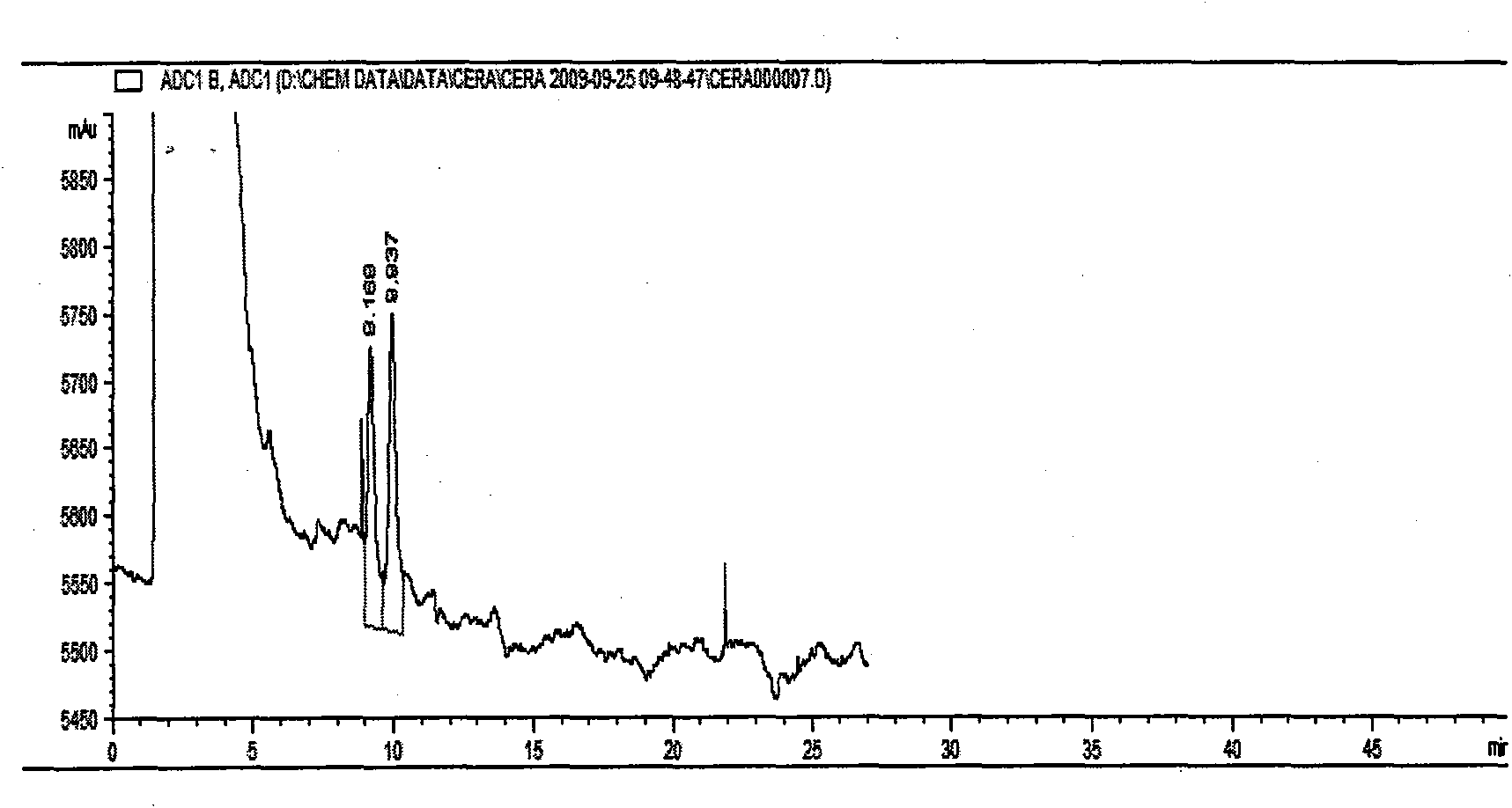

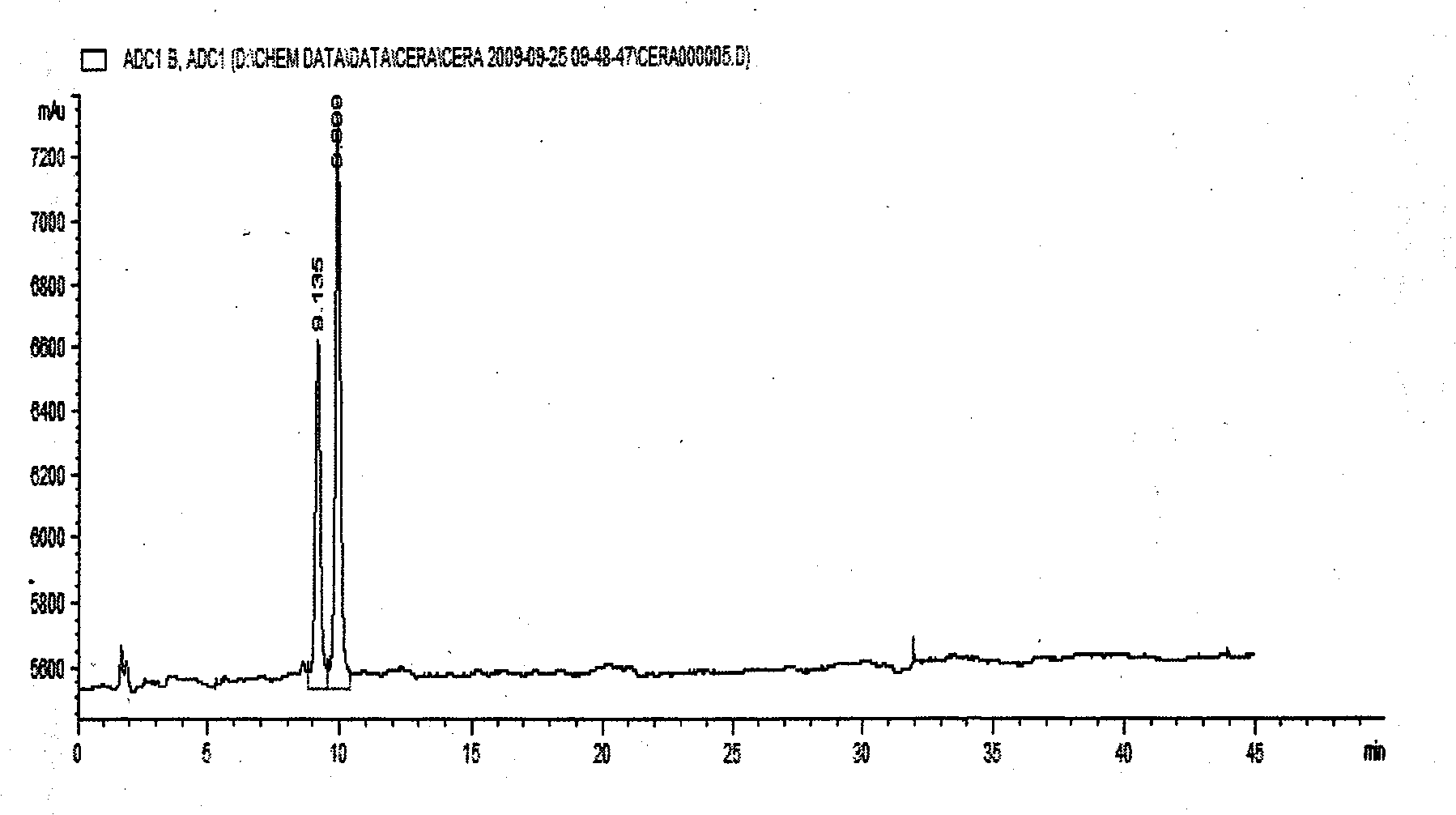

Image

Examples

Embodiment 1

[0026] 1) Extraction and concentration: use the residue of camellia oleifera seeds as raw material after squeezing and extracting the oil and fat components, crush to 20 mesh, put into the extraction container, add 95% (v / v) ethanol equivalent to 3 times the weight of the raw material, and control the temperature at 80 DEG C, reflux extraction for 30 min for the first time, and separate the medicinal solution; add 95% (v / v) ethanol equivalent to 4 times the weight of the raw material for the second time, reflux extraction for 30 min at 80 DEG C, combine the extracts, reduce Press to recover ethanol to obtain extract;

[0027] 2) Hydrolysis: add sodium hydroxide solution equivalent to 5 times the weight of raw materials and a mass concentration of 10% to the extract for hydrolysis, the temperature of hydrolysis is 25 ° C, and the time is 15 hours;

[0028] 3) Extraction: the hydrolyzate is extracted twice with petroleum ether, and the extraction phases are combined; the amount ...

Embodiment 2

[0034] 1) Extraction and concentration: use the residue after extracting oil and fat from camellia seeds as raw material, crush it to 40 mesh, put it into an extraction container, add 90% (v / v) methanol equivalent to 5 times the weight of the raw material, and control the temperature at 60°C , stirring and extracting for 90 minutes, and separating the medicinal liquid; repeating the above conditions and then carrying out the second stirring and extraction; combining the extracts, recovering methanol under reduced pressure, and obtaining an extract;

[0035]2) Hydrolysis: Add potassium hydroxide solution equivalent to 5 times the weight of raw materials and a mass concentration of 10% to the extract for hydrolysis, the temperature of hydrolysis is 50 ° C, and the time is 3 hours;

[0036] 3) Extraction: the hydrolyzate is extracted twice with cyclohexane, and the extract phases are combined; the amount of cyclohexane used for extraction is 1 time of the volume of the hydrolyzate...

Embodiment 3

[0041] 1) Extraction and concentration: use tea tree seeds as raw materials, crush them to 80 mesh, put them into an extraction container, add water equivalent to 10 times the weight of raw materials, heat to 80°C for the first leaching, the time is 10 hours, and separate the drug liquid; for the second time, add water equivalent to 5 times the weight of the raw material, heat to 100 ° C for the second leaching, and the time is 3 hours, and separate the liquid medicine; add water equivalent to 1 time the weight of the raw material for the third time, Heating to 60°C for the third leaching for 1 hour, combining the extracts, concentrating under reduced pressure to obtain the extract;

[0042] 2) Hydrolysis: add sodium carbonate solution equivalent to 0.5 times the weight of raw materials and a mass concentration of 30% to the extract for hydrolysis, the temperature of hydrolysis is 80 ° C, and the time is 1 h;

[0043] 3) The obtained hydrolyzate is separated into the AB-8 type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com