Method for preparing half-fin anchovy antibacterial peptides

An antibacterial peptide and protein technology, which is applied in the field of preparation of the antibacterial peptide of yellow crucian carp protein, and achieves the effects of simple preparation method, good absorption and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

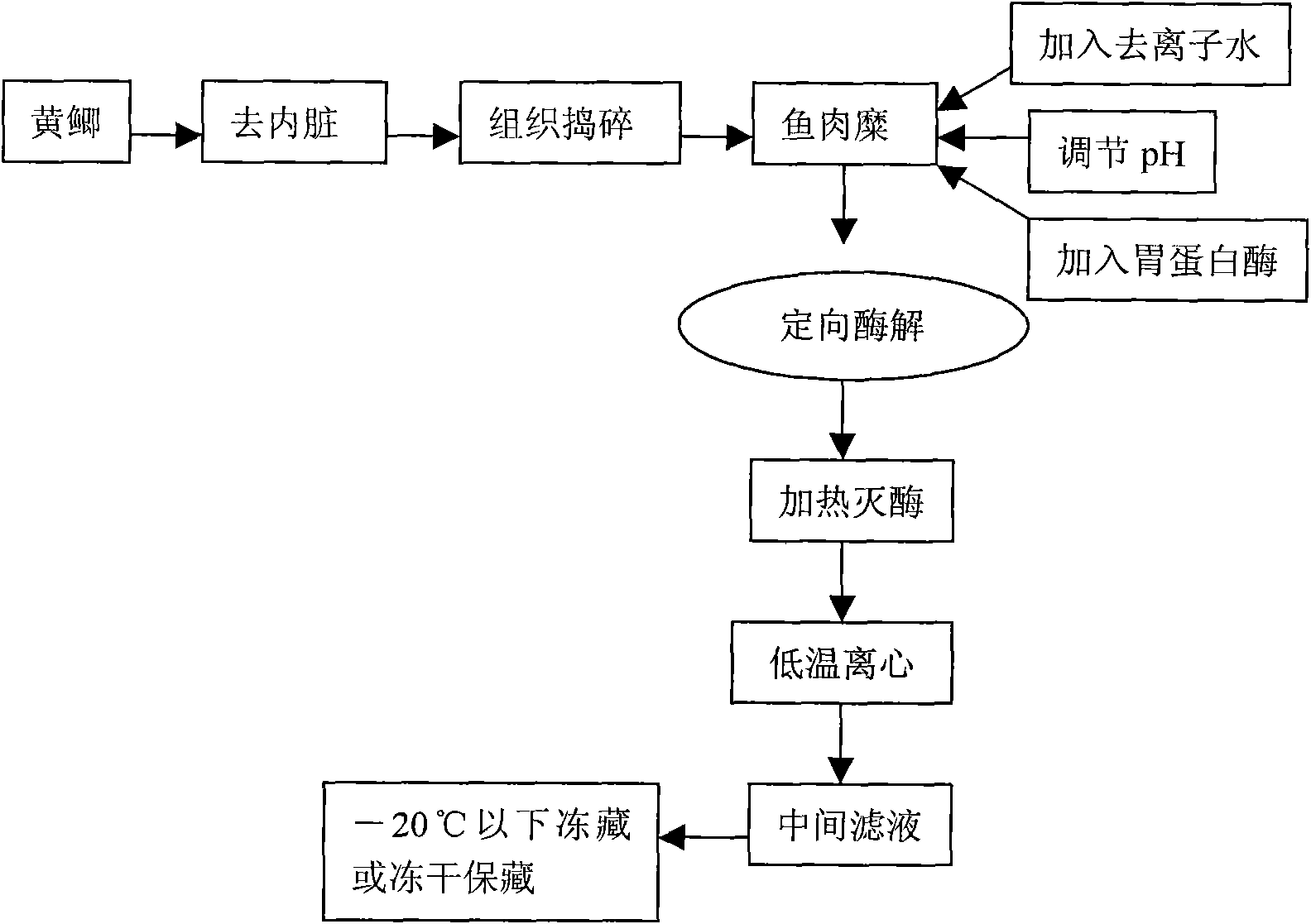

[0020] 1) Remove the internal organs of the yellow crucian carp, wash and cut into small pieces, and use a tissue grinder to grind it evenly to make minced fish. Take 50 grams of minced fish and add 200 grams of deionized water;

[0021] 2) Use 6mol / L hydrochloric acid and 6mol / L sodium hydroxide to adjust the pH value of the minced fish and water mixture to 2.0 and keep it constant;

[0022] 3) Add 55,000 U of pepsin into the mixture, and perform enzymatic hydrolysis for 2.4 hours while maintaining the enzymatic hydrolysis temperature at 37°C;

[0023] 4) Heat up to 95-100°C to passivate and inactivate the enzyme, and the inactivation time is 10 minutes;

[0024] 5) Cool to below 4°C and perform centrifugation for 10 minutes at a speed of 7000r / min;

[0025] 6) Filtrate, and take the intermediate filtrate and store it frozen or freeze-dried at -20°C.

[0026] Trichloroacetic acid precipitation (TCA) combined with Kjeldahl method to determine the extraction rate of soluble p...

Embodiment 2

[0048] 1) Remove the internal organs of the yellow crucian carp, wash and cut into small pieces, and use a tissue grinder to grind it evenly to make minced fish. Take 50 grams of minced fish and add 150 grams of deionized water;

[0049] 2) Use 6mol / L hydrochloric acid and 6mol / L sodium hydroxide to adjust the pH value of the minced fish and water mixture to 2.0 and keep it constant;

[0050] 3) Add 65,000 U of pepsin into the mixture, and perform enzymatic hydrolysis for 3 hours while maintaining the enzymatic hydrolysis temperature at 35°C;

[0051] 4) Heating to 100° C. to passivate and inactivate the enzyme, and the inactivation time is 5 minutes;

[0052] 5) Cool to below 5°C and perform centrifugation for 15 minutes at a speed of 6000r / min;

[0053] 6) Filtrate, and take the intermediate filtrate and store it frozen or freeze-dried at -22°C.

Embodiment 3

[0055] 1) Remove the viscera of the yellow crucian carp, wash and cut into small pieces, and grind it evenly with a tissue grinder to make minced fish. Take 50 grams of minced fish and add 250 grams of deionized water;

[0056] 2) Use 6mol / L hydrochloric acid and 6mol / L sodium hydroxide to adjust the pH value of the minced fish and water mixture to 2.0 and keep it constant;

[0057] 3) Add 50,000 U of pepsin into the mixture, and perform enzymatic hydrolysis for 2 hours while maintaining the enzymatic hydrolysis temperature at 45°C;

[0058] 4) Heat up to 95° C. to passivate and inactivate the enzyme, and the inactivation time is 15 minutes;

[0059] 5) Cool to below 4°C and perform centrifugation for 5 minutes at a speed of 8000r / min;

[0060] 6) Filtrate, and take the intermediate filtrate and store it frozen or freeze-dried at -25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com