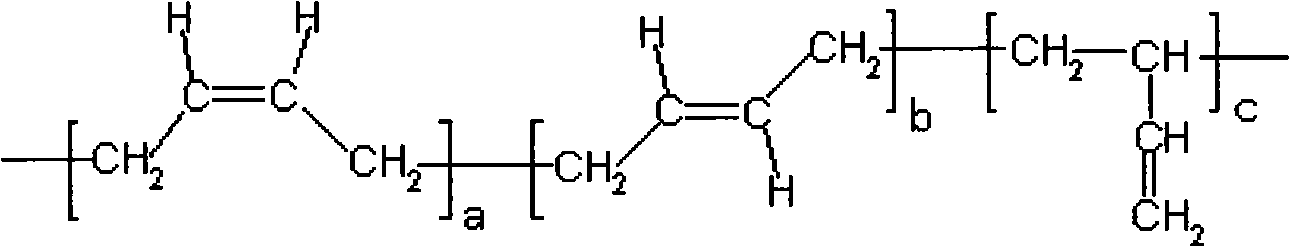

Method for synthesizing continuous body of inflaming retarding ABS (Acrylonitrile Butadiene Styrene)

A synthesis method and bulk synthesis technology are used in the synthesis of ABS and the continuous bulk synthesis of flame retardant ABS, which can solve the problems of large flame retardant particles, poor dispersion effect, long production process, etc. Ease of use and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

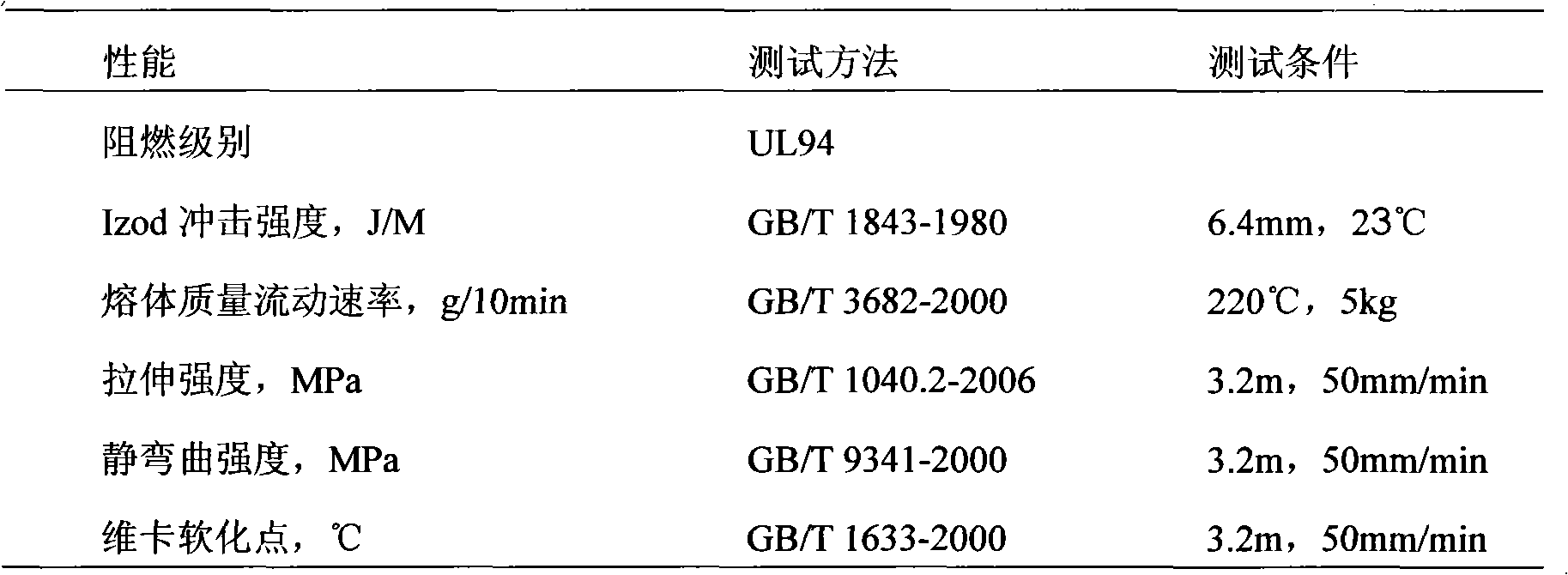

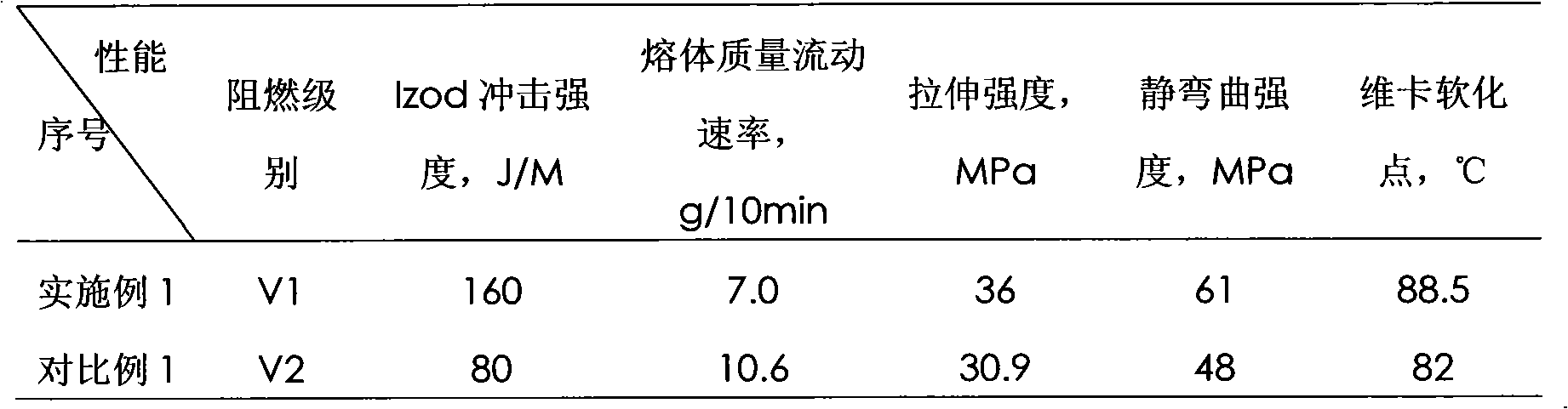

Embodiment 1

[0042] Add 78 parts of styrene, 22 parts of acrylonitrile, 14 parts of ethylbenzene, 11 parts of Firestone 35AC10 polybutadiene rubber, and 14 parts of triphenyl phosphate into the compounding tank. After mixing evenly, add 0.04 parts of tert-butyl peroxynondecanoate, and mix thoroughly, and then add the mixture to the bottom of the first reaction kettle continuously at a speed of 1200 g per hour, and continuously enter the second reaction kettle from the top of the first kettle. Reactor. Add 1% ethylbenzene solution of antioxidant 1076 into the second reaction kettle, the feed rate is 1% of the main feed rate. After the material comes out of the second reaction kettle, it is devolatilized and extruded to make the material to obtain the product. The temperatures of the first reactor and the second reactor were controlled at 90±1°C and 140±1°C respectively, and the stirring speed of each reactor was 120r / min.

Embodiment 2

[0046] Add 83 parts of styrene, 17 parts of acrylonitrile, 13.3 parts of Firestone 35AC10 polybutadiene rubber, and 36.5 parts of triphenyl phosphate into the preparation tank, mix well and then add 0.03 parts of peroxy-2-ethylhexanoic acid tert-butyl ester, and fully mixed, then this mixed solution is continuously added to the bottom of the first reactor at a speed of 1200g per hour, and continuously enters the second reactor from the top of the first reactor. Add 1% ethylbenzene solution of antioxidant 1076 into the second reaction kettle, the feed rate is 1% of the main feed rate. After the material comes out of the second reaction kettle, it is devolatilized and extruded to make the material to obtain the product. The temperatures of the first reactor and the second reactor were controlled at 92±1°C and 150±1°C respectively, and the stirring speed of each reactor was 110r / min.

Embodiment 3

[0050] Add 84 parts of styrene, 16 parts of acrylonitrile, 24.8 parts of ethylbenzene, 11.5 parts of Firestone 721A styrene-butadiene block rubber, and 28 parts of triphenyl phosphate into the preparation tank. After mixing evenly, add 0.03 parts of tert-butyl peroxy-2-ethylhexanoate, and fully mix, then add the mixed solution from the bottom of the kettle continuously at a rate of 2000 g per hour, and there are five reactors in total. Add 1% ethylbenzene solution of antioxidant 1076 in the fourth reaction kettle, and the feed rate is 1% of the main feed rate. The material is directly fed into the devolatilization extruder from the outlet at the top of the last reactor for devolatilization extrusion and material making to obtain the product. The temperature of each reactor is controlled at 90±1°C, 100±1°C, 110±1°C, 130±1°C, 150±1°C, and the stirring speed of each reactor is 130r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com