Polymer, resist composition, and process for producing semiconductor using resist composition

A manufacturing method and polymer technology, applied in semiconductor/solid-state device manufacturing, photoengraving process of pattern surface, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

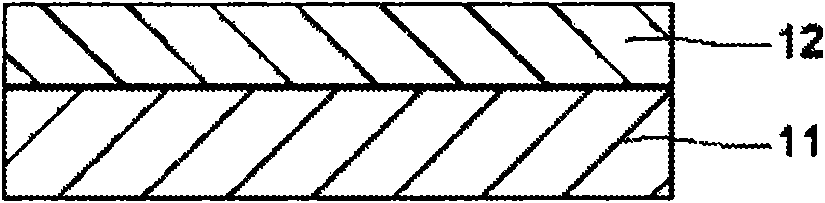

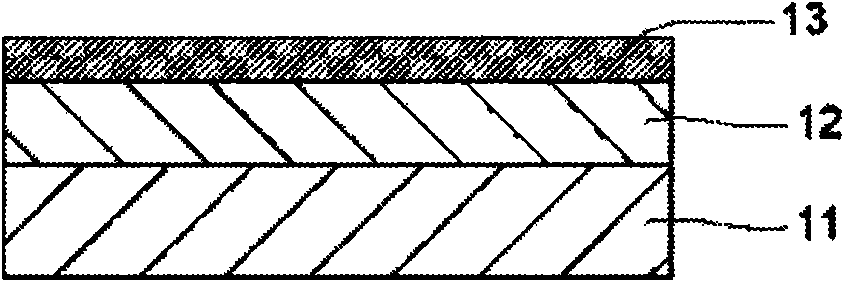

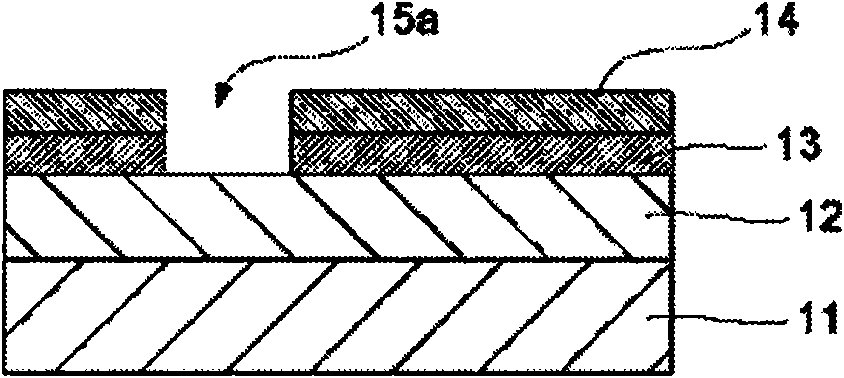

Method used

Image

Examples

Synthetic example 1

[0112] Synthesis of 1,3-Dithianylmethyl Methacrylate (Dithianyl Methyl) (Following Formula (2))

[0113] According to methods known in the literature (Tetrahedron Letters, 41, 5653-5657 (2000)), 3.41 g of 2-hydroxymethyl -1,3-dithiane and 2.3g of triethylamine were added to a 100mL three-necked flask, 40mL of dry dichloromethane was added, and a stirring bar coated with Teflon (Teflon) (registered trademark) was put into the flask under nitrogen atmosphere. , Stirring at 0°C. Through the dropping funnel, 2.3 g of methacryloyl chloride was slowly added, reacted at 0° C. for 2 hours, returned to room temperature, and made to react for another 2 hours. After confirming the disappearance of the starting material by thin layer chromatography (TLC), the reaction solution was poured into a 300mL separatory funnel, washed with 100mL of water, then washed with 100mL of saturated saline (brine), and washed with sodium sulfate to dry. The solvent was distilled off from the obtained so...

Synthetic example 2

[0119] Synthesis of poly(2-methyl-2-adamantyl-methacrylate-1,3-dithianylmethyl methacrylate) (following formula (3))

[0120] Add 1.12g of 2-methyl-2-adamantyl methacrylate and 1.0g of 1,3-dithianylmethyl methacrylate into a 50mL eggplant-shaped flask, add 6.1mL of dioxane (dioxane) , put into a stirring bar coated with Teflon (registered trademark), and blow bubbles with nitrogen for 15 minutes to fully remove oxygen from the reaction system. 0.23 g of AIBN was added as a radical polymerization initiator, and a three-necked flask with a Liebig condenser was placed in an oil bath at 70° C. to react for 5 hours. The obtained reaction solution was cooled to room temperature, diluted to about 25 mL with dioxane, and added dropwise to 500 mL of methanol while stirring to obtain a white precipitate. After filtering and separating with a glass filter, the obtained resin was placed in a vacuum drying oven at 50° C. and dried for 6 hours. The obtained resin was dissolved in about 20...

Embodiment 1 and comparative example 1

[0124] Measurement of Refractive Index

[0125] Using the resin (Example 1) of the above-mentioned Synthesis Example 2 represented by the formula (3) and the general-purpose ArF resist resin (Comparative Example 1) of the following formula (4), with respect to each resin of 100 parts by mass, respectively 750 parts by mass of 2-heptanone and 250 parts by mass of γ-butyrolactone were added to prepare a resin solution. The resulting solution was filtered with a 0.2 μm Teflon (registered trademark) membrane filter to remove particles and the like. The obtained solutions were spin-coated on silicon wafers, respectively, and baked at 110° C. / 60 seconds to form resin films. The refractive index of each resin film was measured using a spectroscopic ellipsometer (GES-5, manufactured by SOPRA). The results are shown in Table 1.

[0126] Formula (4)

[0127] Table 1

[0128] resin Refractive index (400-850nm) Example 1 Formula (3) 1.533 Comparative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com