Zone melting furnace for purifying crystalline silicon and method for purifying crystalline silicon

A technology of crystalline silicon and zone melting furnace, which is applied in the field of silicon preparation technology and equipment, and can solve the problems of small size of the melting zone, many impurities, and single crystal silicon can not meet the purity requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Such as image 3 As shown, the process flow chart of the crystalline silicon preparation method provided by the present invention includes:

[0050] S101: a rough selection process for polysilicon raw materials;

[0051] S102: the selection process of magnetic separation or flotation of polysilicon raw materials;

[0052] S103: performing one or more cleaning processes of high-purity water cleaning, pickling, alkali cleaning, cleaning agent cleaning, and ultrasonic cleaning on the polysilicon raw material;

[0053] S104: preparing crystalline silicon by Czochralski method using polysilicon after the cleaning process as a raw material;

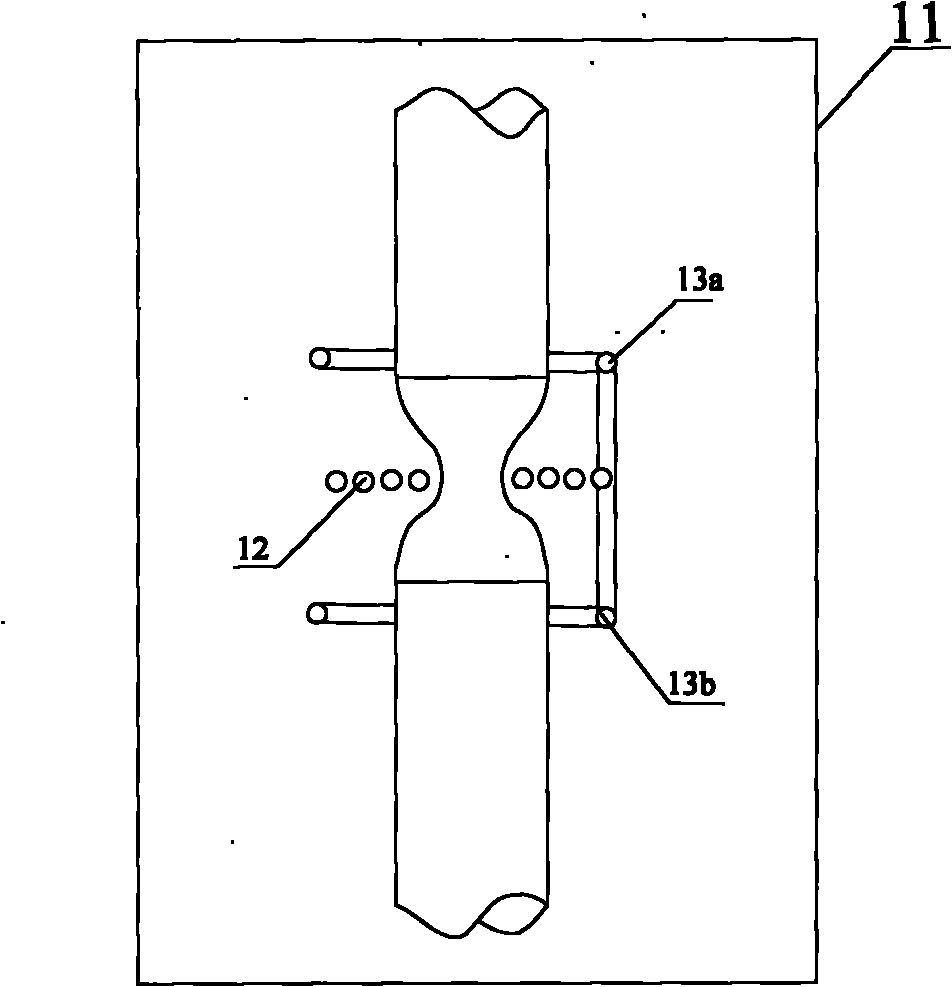

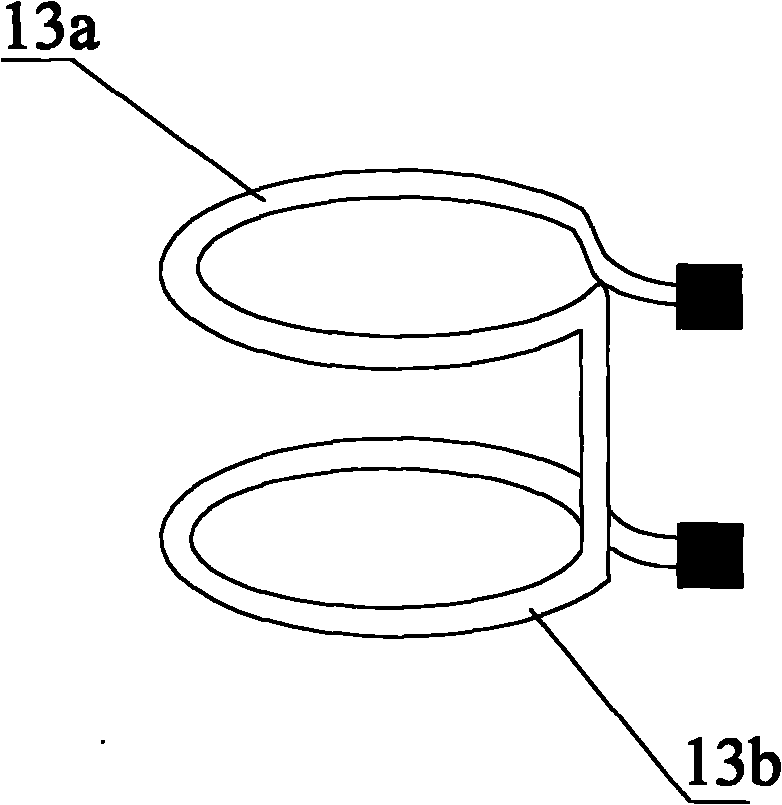

[0054] S105: purifying the crystalline silicon rods by vacuum zone melting or hydrogen zone melting;

[0055] After testing the purified crystalline silicon rods, the crystalline silicon can be purified again with a zone melting furnace, or the process can be terminated.

Embodiment 1

[0058] The polysilicon raw material is a polysilicon mixture of wire saw silicon powder and metallurgical silicon ingot;

[0059] The polysilicon mixture is first roughed in a screening machine;

[0060] Select the polysilicon mixture after rough selection in a magnetic separator with a magnetic field strength of 3000 Oersted;

[0061] For the selected polysilicon mixture, use HNO with a mass ratio concentration of 65% 3 , 40% HF, high-purity water, pickling with a mixed solution with a ratio of 3:1:10, and then cleaning with high-purity water;

[0062] The cleaned polysilicon mixture is placed in a crucible in a Czochralski furnace, and a P-type dopant is added. The Czochralski furnace is a CG-3000 Czochralski furnace made in the United States, and then the crucible is heated to 1550° C. After the polysilicon mixture is melted into a molten state, the seed crystal rotation mechanism is started, the seed crystal is lowered, and the seed crystal is welded to the molten body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com