Heat-insulating coating with spectral selectivity

A nano heat-insulating and selective technology, applied in the direction of radiation-absorbing coatings, reflective/signal coatings, coatings, etc., can solve the problems of unfavorable heat-insulating coatings widely used, long film forming cycle, etc., to achieve enhanced storability, Good heat insulation effect, improve the effect of barrier efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

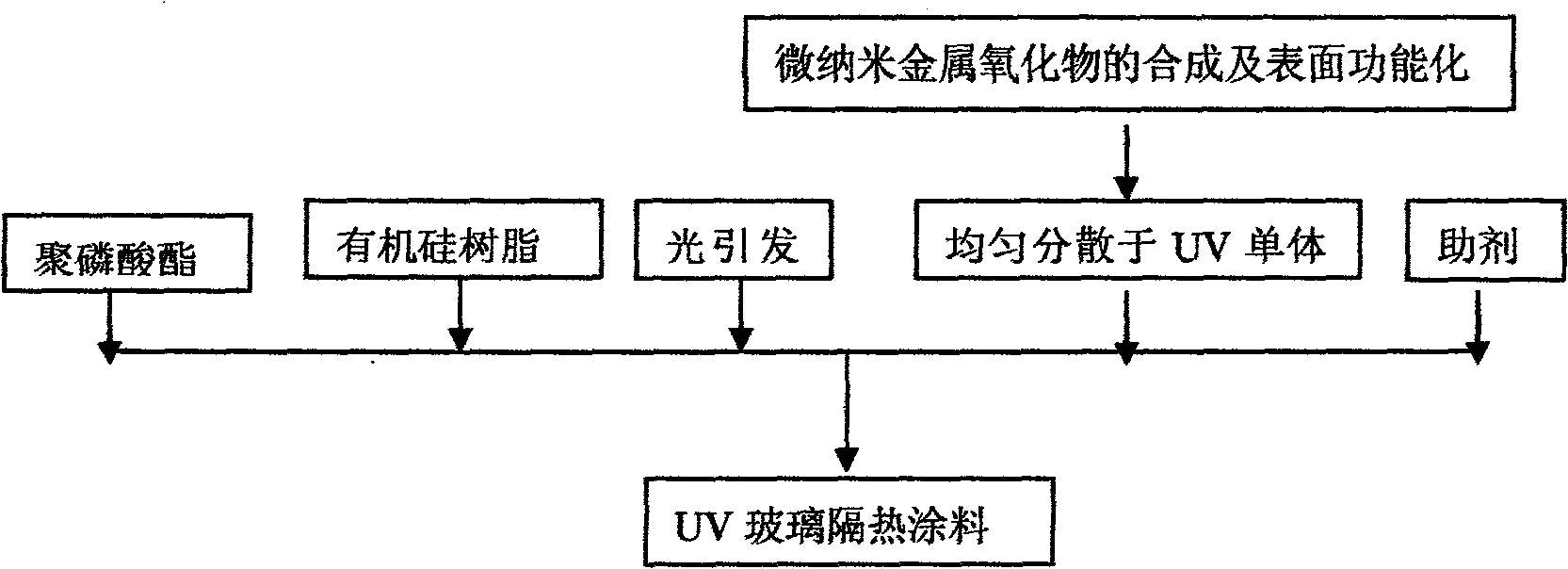

Method used

Image

Examples

Embodiment 1

[0029] Polyphosphate: 30%

[0030] Polyurethane: 20%

[0031] Silicone modified polyacrylic resin: 10%

[0032] Cobalt oxide, TiO 2 with SiO 2 : 10%

[0033] Additives: 1%

[0034] Photoinitiator: 6%

[0035] Monomer: 23%

[0036] This embodiment can be used as a topcoat. All the components are weighed according to the weight ratio, stirred and mixed to form a finished product, which can be directly coated on surfaces such as glass.

Embodiment 2

[0038] Polyphosphate: 25%

[0039] Silicone modified polyacrylic resin: 30%

[0040] Cobalt oxide, TiO 2 , SiO 2 with MnO 2 : 15%

[0041] Auxiliary: 2%

[0042] Photoinitiator: 6%

[0043] Monomer: 22%

[0044] This embodiment can be used as a topcoat. All the components are weighed according to the weight ratio, stirred and mixed to form a finished product, which can be directly coated on surfaces such as glass.

Embodiment 3

[0046] Polyphosphate: 25%

[0047] Polyurethane: 10%

[0048] Silicone modified polyacrylic resin: 15%

[0049] Cobalt oxide, TiO 2 , SiO 2 With CuO: 15%

[0050] Auxiliary: 3%

[0051] Photoinitiator: 5%

[0052] Monomer: 27%

[0053] This embodiment can be used as a topcoat. All the components are weighed according to the weight ratio, stirred and mixed to form a finished product, which can be directly coated on surfaces such as glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com